Chifukwa chomwe mbiri ya aluminiyamu ya aloyi imagwiritsidwa ntchito kwambiri m'moyo ndi kupanga ndikuti aliyense amazindikira bwino zabwino zake monga kutsika kachulukidwe, kukana dzimbiri, madulidwe apamwamba amagetsi, zinthu zopanda ferromagnetic, mawonekedwe, komanso kubwezanso.

Makampani opanga mbiri ya aluminiyamu yaku China yakula kuchokera pachiwopsezo, kuyambira yaying'ono mpaka yayikulu, mpaka idakhala dziko lalikulu lopanga mbiri ya aluminiyamu, lomwe limakhala loyamba padziko lonse lapansi. Komabe, monga momwe msika umafunira kuti zinthu za aluminiyamu zikuchulukirachulukira, kupanga mbiri ya aluminiyamu kwachitika movutikira, kulondola kwambiri, komanso kupanga kwakukulu, komwe kwabweretsa zovuta zingapo zopanga.

Mbiri ya aluminiyamu nthawi zambiri imapangidwa ndi extrusion. Pakupanga, kuwonjezera pa kulingalira ntchito ya extruder, mapangidwe nkhungu, zikuchokera zotayidwa ndodo, kutentha mankhwala ndi zinthu zina ndondomeko, mtanda ndimeyi kamangidwe ka mbiri ayeneranso kuganizira. Mapangidwe abwino kwambiri amtundu wagawo sangangochepetsa zovuta za njira kuchokera ku gwero, komanso kusintha khalidwe ndi ntchito ya mankhwala, kuchepetsa ndalama ndikufupikitsa nthawi yobereka.

Nkhaniyi ikufotokoza mwachidule njira zingapo zomwe zimagwiritsidwa ntchito kwambiri pamapangidwe amtundu wa aluminiyamu kudzera muzochitika zenizeni popanga.

1. Mfundo zopangira gawo la Aluminium profile

Aluminiyamu mbiri extrusion ndi processing njira imene mkangano zotayidwa ndodo yodzaza mu mbiya extrusion, ndi kukakamizidwa ntchito kudzera extruder extruder izo kuchokera kufa dzenje la mawonekedwe anapatsidwa ndi kukula, kuchititsa kupunduka pulasitiki kupeza chofunika mankhwala. Popeza ndodo ya aluminiyamu imakhudzidwa ndi zinthu zosiyanasiyana monga kutentha, kuthamanga kwa extrusion, kuchuluka kwa mapindikidwe, ndi nkhungu pa nthawi yowonongeka, kufanana kwazitsulo kumakhala kovuta kulamulira, zomwe zimabweretsa zovuta pakupanga nkhungu. Pofuna kuonetsetsa mphamvu ya nkhungu ndikupewa ming'alu, kugwa, kupukuta, ndi zina zotero, zotsatirazi ziyenera kupeŵedwa mu kapangidwe ka gawo la mbiri: cantilevers zazikulu, zotseguka zazing'ono, mabowo ang'onoang'ono, porous, asymmetrical, woonda-mipanda, makulidwe a khoma, etc. Popanga, choyamba tiyenera kukwaniritsa ntchito yake pogwiritsira ntchito, kukongoletsa, ndi zina zotero. Chifukwa pamene okonza alibe chidziwitso cha ndondomeko extrusion ndipo samvetsa zofunikira ndondomeko zida, ndi zofunika ndondomeko kupanga ndi okwera kwambiri ndi okhwima, mlingo oyenerera adzachepetsedwa, mtengo adzawonjezeka, ndi mbiri yabwino si kupangidwa. Chifukwa chake, mfundo ya kapangidwe ka gawo la aluminiyamu ndikugwiritsa ntchito njira yosavuta momwe mungathere ndikukwaniritsa mawonekedwe ake.

2. Malangizo ena pa kapangidwe ka mawonekedwe a aluminiyamu

2.1 Kubweza zolakwika

Kutseka ndi chimodzi mwa zolakwika zomwe zimachitika pakupanga mbiri. Zifukwa zazikulu ndi izi:

(1) Mbiri yokhala ndi mipata yozama kwambiri imatseka ikatulutsidwa.

(2) Kutambasula ndi kuwongola mbiri kudzakulitsa kutseka.

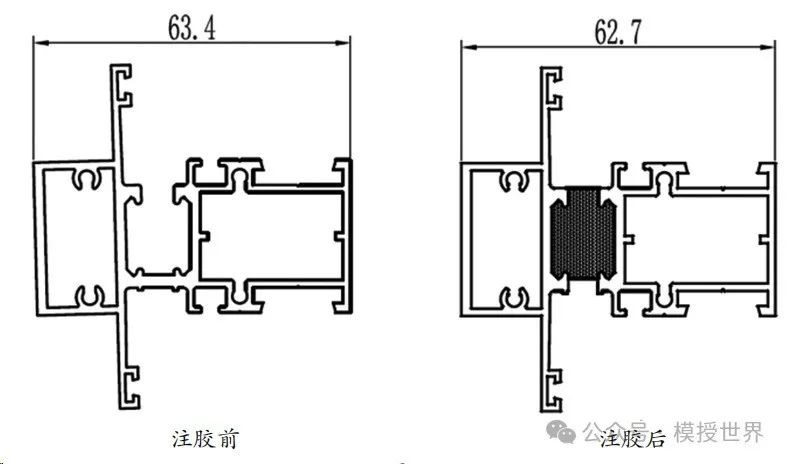

(3) Ma profayilo ojambulidwa ndi zomatira okhala ndi zida zina adzakhalanso ndi kutseka chifukwa cha kuchepa kwa colloid pambuyo jekeseni guluu.

Ngati kutsekedwa kotchulidwa pamwambapa sikuli koopsa, kungapewedwe mwa kuwongolera kuthamanga kwa kayendedwe ka nkhungu; koma ngati zinthu zingapo zili pamwamba ndipo mapangidwe a nkhungu ndi njira zokhudzana nazo sizingathe kuthetsa kutseka, chiwongoladzanja chisanachitike chingaperekedwe mu mapangidwe a gawo, ndiko kuti, kutsegulira.

Kuchuluka kwa chiwongoladzanja chotsegulira chisanadze chiyenera kusankhidwa malinga ndi dongosolo lake lenileni ndi zomwe zatsekeredwa kale. Panthawiyi, mapangidwe a chojambula chotsegulira nkhungu (kutsegula chisanadze) ndi chojambula chomaliza ndi chosiyana (Chithunzi 1).

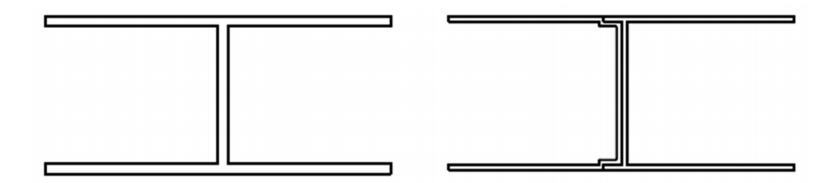

2.2 Gawani zigawo zazikuluzikulu m'zigawo zingapo zazing'ono

Ndi chitukuko cha mbiri zazikulu za aluminiyamu, mapangidwe amtundu wa ma profayilo ambiri akukulirakulira, zomwe zikutanthauza kuti zida zingapo monga ma extruders akuluakulu, nkhungu zazikulu, ndodo zazikulu za aluminiyamu, ndi zina zotero zimafunika kuti ziwathandize, ndipo ndalama zopangira zimakwera kwambiri. Pazigawo zina zazikuluzikulu zomwe zingatheke pophatikizana, ziyenera kugawidwa m'magawo angapo ang'onoang'ono panthawi yopanga. Izi sizingachepetse ndalama zokha, komanso zimapangitsa kuti zikhale zosavuta kuonetsetsa kuti flatness, kupindika, ndi kulondola (Chithunzi 2).

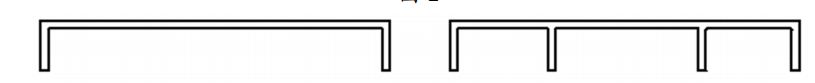

2.3 Khazikitsani nthiti zolimbitsa kuti ziwongolere kusalala kwake

Zofunikira za flatness nthawi zambiri zimakumana popanga magawo a mbiri. Mafotokozedwe ang'onoang'ono ndi osavuta kuonetsetsa kuti ali ophwanyika chifukwa cha mphamvu zawo zapamwamba. Mbiri zazitali zidzagwa chifukwa cha mphamvu yokoka itangotuluka, ndipo gawo lomwe lili ndi kupsinjika kwakukulu kopindika pakati lidzakhala lopindika kwambiri. Komanso, chifukwa gulu la khoma ndi lalitali, n'zosavuta kupanga mafunde, zomwe zidzawonjezera kufalikira kwa ndege. Chifukwa chake, mapangidwe a mbale zazikulu zazikuluzikulu ziyenera kupewedwa pamapangidwe apakati. Ngati ndi kotheka, kulimbitsa nthiti akhoza anaika pakati kusintha flatness ake. (Chithunzi 3)

2.4 Secondary processing

Mu ndondomeko yopanga mbiri, zigawo zina zimakhala zovuta kumaliza ndi extrusion processing. Ngakhale zitha kuchitika, mtengo wokonza ndi kupanga udzakhala wokwera kwambiri. Panthawiyi, njira zina zogwirira ntchito zikhoza kuganiziridwa.

Mlandu 1: Mabowo okhala ndi mainchesi osakwana 4mm pagawo lambiri amapangitsa nkhungu kukhala yosakwanira mphamvu, yowonongeka mosavuta, komanso yovuta kuyikonza. Ndibwino kuti muchotse mabowo ang'onoang'ono ndikugwiritsa ntchito kubowola m'malo mwake.

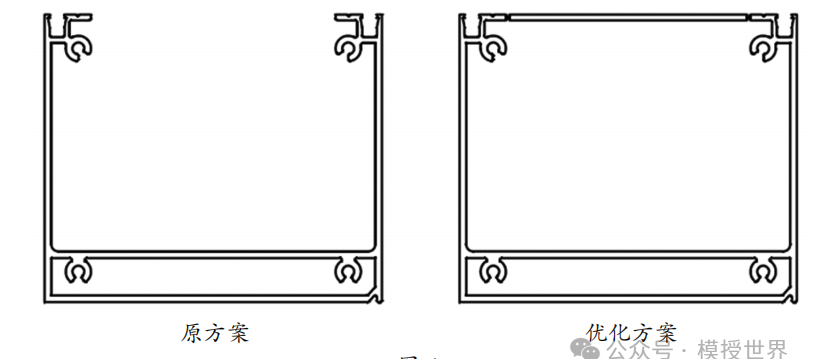

Mlandu wa 2: Kupanga ma groove wamba ooneka ngati U sikovuta, koma ngati kuya kwa groove ndi m'lifupi mwake kupitilira 100mm, kapena chiŵerengero cha m'lifupi mwake mpaka kuzama kwa groove sichanzeru, mavuto monga kusakwanira kwa nkhungu ndi zovuta pakuwonetsetsa kuti kutsegulira kudzakumananso panthawi yopanga. Popanga gawo la mbiri, kutsegula kungaganizidwe kuti kwatsekedwa, kotero kuti nkhungu yoyambirira yolimba yokhala ndi mphamvu zosakwanira ikhoza kusinthidwa kukhala nkhungu yogawanika yokhazikika, ndipo sipadzakhala vuto lotsegula mapindikidwe panthawi ya extrusion, kupanga mawonekedwe osavuta kusunga. Kuphatikiza apo, zina zitha kuchitika pakulumikizana pakati pa malekezero awiri otsegulira panthawi yopanga. Mwachitsanzo: ikani zizindikiro zooneka ngati V, ma grooves ang'onoang'ono, ndi zina zotero, kuti athe kuchotsedwa mosavuta panthawi yokonza makina omaliza (Chithunzi 4).

2.5 Zovuta kunja koma zosavuta mkati

Aluminiyamu mbiri extrusion zisamere pachakudya akhoza kugawidwa mu zisamere pachakudya zolimba ndi shunt zisamere pachakudya malinga ngati gawo mtanda ali patsekeke. Kukonzekera kwa nkhungu zolimba kumakhala kosavuta, pamene kukonza nkhungu za shunt kumaphatikizapo njira zovuta kwambiri monga mapanga ndi mitu yapakati. Choncho, kuganizira mozama kuyenera kuperekedwa ku mapangidwe a gawo la mbiriyo, ndiko kuti, mawonekedwe akunja a gawolo akhoza kupangidwa kuti akhale ovuta kwambiri, ndipo grooves, mabowo opopera, ndi zina zotero ziyenera kuikidwa pamtunda momwe zingathere, pamene mkati mwake ayenera kukhala ophweka momwe angathere, ndipo zofunikira zolondola sizingakhale zapamwamba kwambiri. Mwanjira imeneyi, kukonza ndi kukonza nkhungu kudzakhala kosavuta, ndipo zokolola zidzasinthanso.

2.6 malire osungidwa

Pambuyo extrusion, mbiri aluminiyamu ndi osiyana njira mankhwala pamwamba malinga ndi zosowa za makasitomala. Pakati pawo, njira za anodizing ndi electrophoresis sizimakhudza kukula kwake chifukwa cha filimu yopyapyala. Ngati njira yochizira pamwamba pa kupaka ufa ikugwiritsidwa ntchito, ufa umatha kudziunjikira m'ngodya ndi grooves, ndipo makulidwe a wosanjikiza umodzi amatha kufika 100 μm. Ngati ili ndi malo a msonkhano, monga slider, zikutanthauza kuti pali zigawo zinayi za zokutira zopopera. Kukula mpaka 400 μm kumapangitsa kuti msonkhano ukhale wosatheka komanso umakhudza kugwiritsidwa ntchito.

Kuonjezera apo, pamene chiwerengero cha extrusions chikuwonjezeka ndipo nkhungu imavala, kukula kwa malo otsetsereka kudzakhala kochepa komanso kakang'ono, pamene kukula kwa slider kudzakhala kokulirapo komanso kukulirakulira, zomwe zimapangitsa msonkhano kukhala wovuta kwambiri. Kutengera pazifukwa zomwe zili pamwambazi, malire oyenerera ayenera kusungidwa molingana ndi zikhalidwe zinazake pakapangidwe kuti awonetsetse kuti asonkhanitsidwa.

2.7 Chizindikiro cha kulolerana

Pamapangidwe amitundu yosiyanasiyana, chojambula chapagulu chimapangidwa poyamba ndiyeno chojambula chambiri chimapangidwa. Kujambula koyenera kwa msonkhano sikukutanthauza kuti zojambula zamtundu wambiri ndi zangwiro. Okonza ena amanyalanyaza kufunika kwa miyeso ndi kulolerana chizindikiro. Malo olembedwa nthawi zambiri amakhala miyeso yomwe imayenera kutsimikiziridwa, monga: malo osonkhanitsira, kutseguka, kuzama kwa poyambira, m'lifupi mwaphoko, ndi zina zotero, ndipo ndizosavuta kuyeza ndikuwunika. Kwa kulolerana kwapang'onopang'ono, mulingo wolondola wofananira ukhoza kusankhidwa molingana ndi muyezo wadziko. Zina zofunika zomangirira ziyenera kuzindikirika ndi kulolerana kwapadera pachithunzichi. Ngati kulekerera kuli kwakukulu kwambiri, msonkhano udzakhala wovuta kwambiri, ndipo ngati kulekerera kuli kochepa kwambiri, mtengo wopangira udzawonjezeka. Kulekerera koyenera kumafuna kudzikundikira kwa tsiku ndi tsiku kwa wopanga.

2.8 Zosintha mwatsatanetsatane

Tsatanetsatane imatsimikizira kupambana kapena kulephera, ndipo zomwezo ndizofanana ndi mapangidwe amitundu yosiyanasiyana. Kusintha kwakung'ono sikungangoteteza nkhungu ndikuwongolera kuthamanga kwa magazi, komanso kuwongolera mawonekedwe a pamwamba ndikuwonjezera kuchuluka kwa zokolola. Imodzi mwa njira zomwe zimagwiritsidwa ntchito kwambiri ndikuzungulira ngodya. Ma profiles owonjezera sangakhale ndi ngodya zakuthwa kwenikweni chifukwa mawaya owonda amkuwa omwe amagwiritsidwa ntchito podula mawaya alinso ndi ma diameter. Komabe, kuthamanga kothamanga pamakona ndi pang'onopang'ono, kukangana ndi kwakukulu, ndipo kupanikizika kumakhazikika, nthawi zambiri pamakhala zochitika zomwe zizindikiro za extrusion zimakhala zoonekeratu, kukula kwake kumakhala kovuta kulamulira, ndipo nkhungu zimakhala zosavuta kuphulika. Chifukwa chake, utali wozungulira uyenera kukulitsidwa momwe mungathere popanda kusokoneza kugwiritsidwa ntchito kwake.

Ngakhale atapangidwa ndi makina ang'onoang'ono a extrusion, makulidwe a khoma la mbiriyo sikuyenera kukhala osachepera 0.8mm, ndipo makulidwe a khoma la gawo lililonse la gawoli sayenera kusiyana nthawi zoposa 4. Pakupanga, mizere ya diagonal kapena kusintha kwa arc kutha kugwiritsidwa ntchito pakusintha kwadzidzidzi kwa makulidwe a khoma kuti muwonetsetse mawonekedwe otulutsa nthawi zonse komanso kukonza nkhungu mosavuta. Kuphatikiza apo, ma profiles okhala ndi mipanda yopyapyala amakhala ndi elasticity yabwino, ndipo makulidwe a khoma la ma gussets, ma battens, ndi zina zambiri amatha kukhala pafupifupi 1mm. Pali ntchito zambiri zosinthira tsatanetsatane mu kapangidwe kake, monga kusintha ma angles, kusintha mayendedwe, kufupikitsa cantilevers, mipata yowonjezera, kuwongolera ma symmetry, kusintha kulolerana, etc. Mwachidule, kapangidwe kake kagawo kakang'ono kambiri kumafuna chidule chokhazikika komanso chatsopano, ndikuganizira kwathunthu mgwirizano ndi kapangidwe ka nkhungu, kupanga, ndi kupanga.

3. Mapeto

Monga wopanga, kuti mupeze phindu labwino kwambiri lazachuma kuchokera pakupanga mbiri, zinthu zonse za moyo wonse wazinthu ziyenera kuganiziridwa panthawi yopangira, kuphatikiza zosowa za ogwiritsa ntchito, mapangidwe, kupanga, mtundu, mtengo, ndi zina zambiri, yesetsani kukwaniritsa chipambano chachitukuko choyamba. Izi zimafuna kutsata tsiku ndi tsiku za kapangidwe kazinthu ndi kusonkhanitsa ndi kusonkhanitsa zidziwitso zodziwikiratu kuti mulosere zotsatira za kapangidwe kake ndikuzikonza pasadakhale.

Nthawi yotumiza: Sep-10-2024