1.Chiyambi

Kuwala kwa magalimoto kunayamba m'maiko otukuka ndipo poyambilira kumatsogozedwa ndi zimphona zamagalimoto zamagalimoto. Ndi chitukuko chosalekeza, chawonjezeka kwambiri. Kuyambira nthawi yomwe Amwenye adagwiritsa ntchito aloyi ya aluminiyamu kupanga ma crankshafts amagalimoto kupita ku Audi yoyamba kupanga magalimoto onse a aluminiyamu mu 1999, aloyi ya aluminiyamu yawona kukula kwamphamvu pamagalimoto ogwiritsira ntchito magalimoto chifukwa cha zabwino zake monga kachulukidwe otsika, mphamvu zenizeni zenizeni ndi kuuma, kulimba kwabwino komanso kulimba, kulimba kwamphamvu, kukana kwamphamvu komanso kusinthika kwakukulu. Pofika chaka cha 2015, gawo la ntchito ya aloyi ya aluminiyamu m'galimoto linali litadutsa kale 35%.

Kuwala kwamagalimoto aku China kudayamba zosakwana zaka 10 zapitazo, ndipo ukadaulo ndi magwiridwe antchito zimatsalira kumayiko otukuka monga Germany, United States, ndi Japan. Komabe, ndi chitukuko cha magalimoto atsopano mphamvu, zinthu lightweighting ikupita mofulumira. Pogwiritsa ntchito kukwera kwa magalimoto amagetsi atsopano, ukadaulo waku China wopepuka wopepuka wagalimoto ukuwonetsa chizolowezi chofikira mayiko otukuka.

Msika wazinthu zopepuka waku China ndi waukulu. Kumbali imodzi, poyerekeza ndi mayiko otukuka akunja, ukadaulo wopepuka waku China unayamba mochedwa, ndipo kulemera kwagalimoto yonse ya Curb ndikokulirapo. Poganizira za kuchuluka kwa zida zopepuka m'maiko akunja, pali malo okwanira otukuka ku China. Kumbali inayi, motsogozedwa ndi mfundo, kutukuka kwachangu kwamakampani opanga magalimoto aku China kudzakulitsa kufunikira kwa zida zopepuka komanso kulimbikitsa makampani amagalimoto kuti atsogolere kuzinthu zopepuka.

Kuwongolera kwamafuta otulutsa komanso kugwiritsa ntchito mafuta kukukakamiza kukwera kwa kuyatsa kwa magalimoto. China idakwaniritsa bwino miyezo ya China VI yotulutsa mpweya mu 2020. Malinga ndi "Kuwunika Njira ndi Zizindikiro Zogwiritsira Ntchito Mafuta a Magalimoto Okwera" ndi "Kupulumutsa Mphamvu ndi New Energy Vehicle Technology Roadmap," ndi 5.0 L/km kugwiritsa ntchito mafuta. Poganizira za malo ochepa oti achite bwino kwambiri paukadaulo wa injini ndi kuchepetsa mpweya, kugwiritsa ntchito njira zopangira zida zamagalimoto zopepuka kumatha kuchepetsa kutulutsa kwamagalimoto komanso kugwiritsa ntchito mafuta. Kuchepetsa mphamvu zamagalimoto atsopano kwakhala njira yofunikira pakukula kwamakampani.

Mu 2016, bungwe la China Automotive Engineering Society linapereka "Kupulumutsa Mphamvu ndi New Energy Vehicle Technology Roadmap," yomwe inakonza zinthu monga mphamvu yogwiritsira ntchito mphamvu, maulendo oyendayenda, ndi zipangizo zopangira magalimoto atsopano amphamvu kuchokera ku 2020 mpaka 2030. Kuwala kopepuka kudzakhala chitsogozo chofunikira pa chitukuko chamtsogolo cha magalimoto atsopano amphamvu. Kupepuka kumatha kukulitsa maulendo oyenda ndikuwongolera "nkhawa zosiyanasiyana" pamagalimoto atsopano amphamvu. Pakuchulukirachulukira kwa maulendo ataliatali, kuyatsa magalimoto kumakhala kofunika, ndipo kugulitsa magalimoto amphamvu zatsopano kwakula kwambiri m'zaka zaposachedwa. Malinga ndi zomwe zimafunikira pamakina ndi "Mid-to-Term-Term Development Plan for the Automotive Industry," akuti pofika chaka cha 2025, malonda aku China amagetsi atsopano adzadutsa mayunitsi 6 miliyoni, ndikukula kwapachaka kupitilira 38%.

2.Makhalidwe a Aluminium Alloy ndi Mapulogalamu

2.1 Makhalidwe a Aluminium Alloy

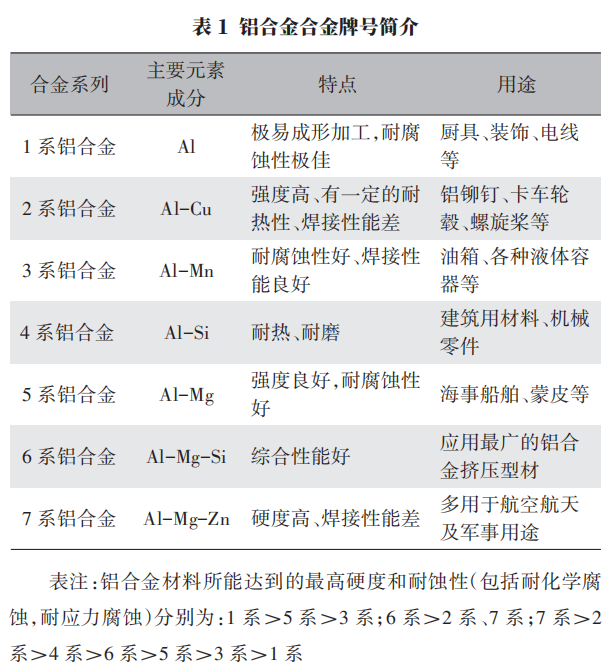

Kuchulukana kwa aluminiyumu ndi gawo limodzi mwa magawo atatu a chitsulo, kupangitsa kuti ikhale yopepuka. Ili ndi mphamvu zapadera kwambiri, kuthekera kwabwino kwa extrusion, kukana kwa dzimbiri kolimba, komanso kubwezanso kwambiri. Ma aluminiyamu aloyi amadziwika kuti makamaka amapangidwa ndi magnesium, kusonyeza kukana kutentha, katundu wabwino kuwotcherera, zabwino kutopa mphamvu, kulephera kulimbikitsidwa ndi kutentha mankhwala, ndi luso kuonjezera mphamvu mwa ntchito ozizira. Mndandanda wa 6 umadziwika kuti umapangidwa makamaka ndi magnesium ndi silicon, ndi Mg2Si monga gawo lalikulu lolimbikitsa. Ma aloyi omwe amagwiritsidwa ntchito kwambiri m'gululi ndi 6063, 6061, ndi 6005A. 5052 aluminiyamu mbale ndi AL-Mg mndandanda aloyi aluminiyamu mbale, ndi magnesium monga chinthu chachikulu aloyi. Ndilo aluminiyamu yotsutsana ndi dzimbiri yomwe imagwiritsidwa ntchito kwambiri. Aloyiyi imakhala ndi mphamvu zambiri, mphamvu yotopa kwambiri, pulasitiki yabwino komanso kukana kwa dzimbiri, sungalimbikitsidwe ndi chithandizo cha kutentha, imakhala ndi pulasitiki yabwino pakugwira ntchito mozizira kwambiri, kutsika kwa pulasitiki mu ntchito yozizira kuuma, kukana kwa dzimbiri, ndi zinthu zabwino zowotcherera. Amagwiritsidwa ntchito makamaka pazinthu monga mapanelo am'mbali, zophimba padenga, ndi zitseko. 6063 aluminiyamu alloy ndi aloyi kulimbikitsa kutentha mu mndandanda AL-Mg-Si, ndi magnesium ndi silicon monga zinthu zazikulu alloying. Ndi mawonekedwe a aluminiyamu ochiritsira omwe amalimbitsa kutentha ndi mphamvu yapakatikati, yomwe imagwiritsidwa ntchito kwambiri pazinthu zamapangidwe monga mizati ndi mapanelo am'mbali kuti anyamule mphamvu. Chiyambi cha magawo a aluminiyamu aloyi chikuwonetsedwa mu Gulu 1.

2.2 Extrusion ndi Njira Yofunika Yopangira Aluminiyamu Aloyi

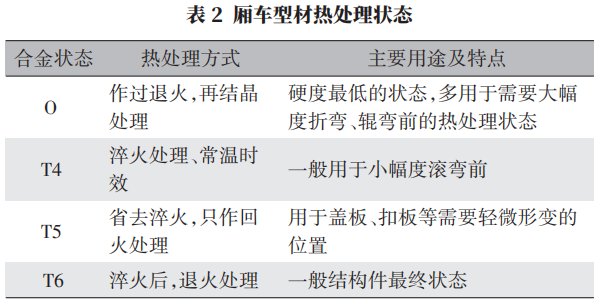

Aluminiyamu alloy extrusion ndi njira yotentha yopangira, ndipo njira yonse yopanga imaphatikizapo kupanga aloyi ya aluminiyamu pansi pa kupsinjika kwa njira zitatu. Njira yonse yopangira zinthu itha kufotokozedwa motere: a. Aluminiyamu ndi ma aloyi ena amasungunuka ndikuponyedwa muzitsulo zofunikira za aluminiyamu; b. Ma billets otenthedwa amayikidwa mu zida za extrusion kuti zitheke. Pansi pa zochita za silinda yayikulu, aluminium alloy billet imapangidwa m'magawo ofunikira kudzera pakhungu la nkhungu; c. Pofuna kukonza mawotchi amtundu wa aluminiyamu, chithandizo chamankhwala chimachitika panthawi kapena pambuyo pa extrusion, ndikutsatiridwa ndi chithandizo chaukalamba. The makina katundu pambuyo ukalamba mankhwala zimasiyanasiyana malinga ndi zipangizo zosiyanasiyana ndi ukalamba maulamuliro. Mkhalidwe wa kutentha kwambiri zamagalimoto amtundu wa bokosi akuwonetsedwa mu Gulu 2.

Aluminiyamu aloyi extruded mankhwala ali ndi ubwino angapo kuposa kupanga njira zina:

a. Pa extrusion, ndi extruded zitsulo amapeza amphamvu ndi yunifolomu njira zitatu compressive kupsyinjika mu zone mapindikidwe kuposa kugubuduza ndi forging, kotero akhoza mokwanira kusewera plasticity wa kukonzedwa zitsulo. Itha kugwiritsidwa ntchito popanga zitsulo zovuta kupotoza zomwe sizingasinthidwe ndi kugubuduza kapena kufota ndipo zitha kugwiritsidwa ntchito popanga zida zosiyanasiyana zopanda kanthu kapena zolimba.

b. Chifukwa ma geometry a aluminiyamu amtundu wa aluminiyumu amatha kukhala osiyanasiyana, zigawo zawo zimakhala ndi kuuma kwakukulu, zomwe zingapangitse kuti thupi la galimoto likhale lolimba, kuchepetsa makhalidwe ake a NVH, ndikuwongolera machitidwe oyendetsa galimoto.

c. Zogulitsa zomwe zimakhala ndi mphamvu zowonjezera, pambuyo pozimitsa ndi kukalamba, zimakhala ndi mphamvu zotalika kwambiri (R, Raz) kuposa zomwe zimagwiritsidwa ntchito ndi njira zina.

d. Pamwamba pa zinthu pambuyo extrusion ali ndi mtundu wabwino ndi kukana dzimbiri, kuthetsa kufunika zina odana dzimbiri pamwamba mankhwala.

e. Extrusion processing ali kusinthasintha kwambiri, otsika tooling ndi nkhungu ndalama, ndi otsika mtengo kusintha kamangidwe.

f. Chifukwa cha controllability a aluminiyamu mbiri mtanda zigawo, mlingo wa kusakanikirana chigawo akhoza ziwonjezeke, chiwerengero cha zigawo zikuluzikulu akhoza kuchepetsedwa, ndi mapangidwe osiyana mtanda gawo akhoza kukwaniritsa yeniyeni kuwotcherera udindo.

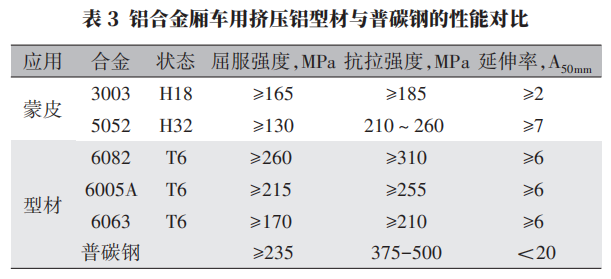

Kuyerekeza kwa magwiridwe antchito pakati pa mbiri ya aluminiyamu yotulutsidwa pamagalimoto amtundu wa bokosi ndi chitsulo chopanda kaboni chawonetsedwa mu Gulu 3.

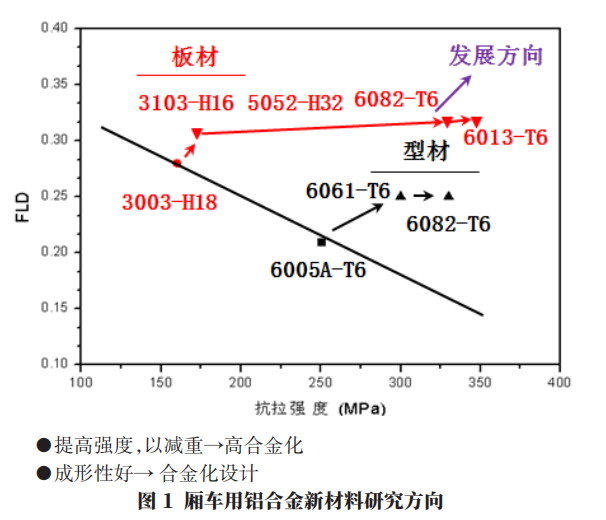

Njira Yotsatira Yachitukuko cha Mbiri ya Aluminium Alloy ya Magalimoto amtundu wa Box: Kupititsa patsogolo mphamvu za mbiri ndikuwonjezera magwiridwe antchito. Kafufuzidwe kazinthu zatsopano zama profiles a aluminiyamu aloyi zamagalimoto amtundu wa bokosi akuwonetsedwa pazithunzi 1.

3.Aluminium Alloy Box Truck Structure, Strength Analysis, ndi Verification

3.1 Aluminiyamu Alloy Box Kapangidwe ka Truck

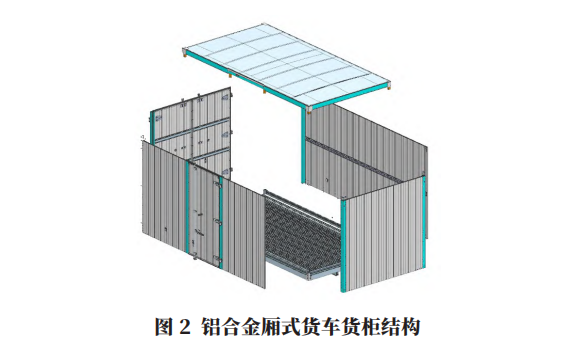

Bokosi galimoto chidebe makamaka tichipeza gulu gulu msonkhano, kumanzere ndi kumanja gulu gulu msonkhano, kumbuyo chitseko mbali gulu msonkhano, msonkhano pansi, msonkhano denga, komanso mabawuti U-woboola pakati, alonda mbali, alonda kumbuyo, matope flaps, ndi zipangizo zina olumikizidwa kwa chassis kalasi yachiwiri. Bokosi thupi mtanda matabwa, mizati, mbali matabwa, ndi mapanelo zitseko anapangidwa ndi aluminiyamu aloyi extruded mbiri, pamene pansi ndi mapanelo padenga amapangidwa ndi 5052 zotayidwa aloyi mbale lathyathyathya. Mapangidwe a galimoto ya aluminiyamu alloy box akuwonetsedwa mu Chithunzi 2.

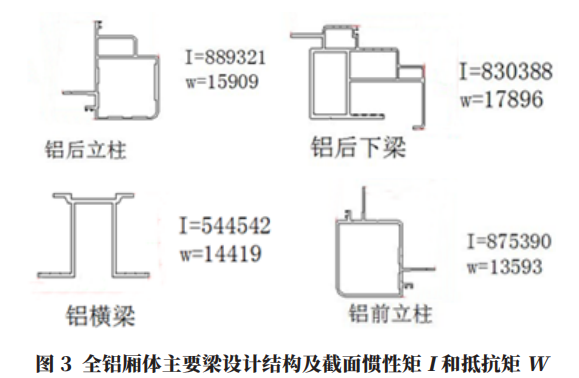

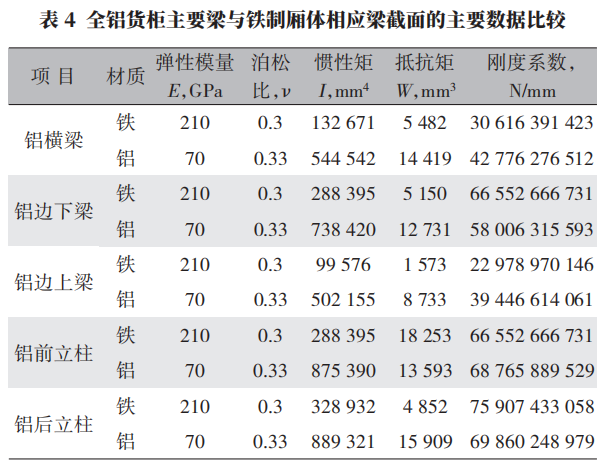

Kugwiritsa ntchito kutentha extrusion ndondomeko 6 mndandanda zotayidwa aloyi akhoza kupanga zovuta dzenje mtanda zigawo, kamangidwe ka mbiri zotayidwa ndi zovuta mtanda zigawo akhoza kupulumutsa zipangizo, kukumana ndi zofunika za mankhwala mphamvu ndi stiffness, ndi kukwaniritsa zofunika kugwirizana pakati pa zigawo zosiyanasiyana. Chifukwa chake, kapangidwe kake kakang'ono ka mtengo ndi mphindi za inertia I ndi mphindi zotsutsa W zikuwonetsedwa pazithunzi 3.

Kuyerekeza kwa deta yayikulu mu Table 4 kukuwonetsa kuti nthawi zapagawo za inertia ndi kukana kwa mbiri yopangidwa ndi aluminiyamu ndizopambana kuposa zomwe zikugwirizana ndi mbiri yamtengo wopangidwa ndi chitsulo. Deta ya coefficient ya kuuma imakhala yofanana ndi mbiri yachitsulo yopangidwa ndi chitsulo, ndipo zonse zimakwaniritsa zofunikira za deformation.

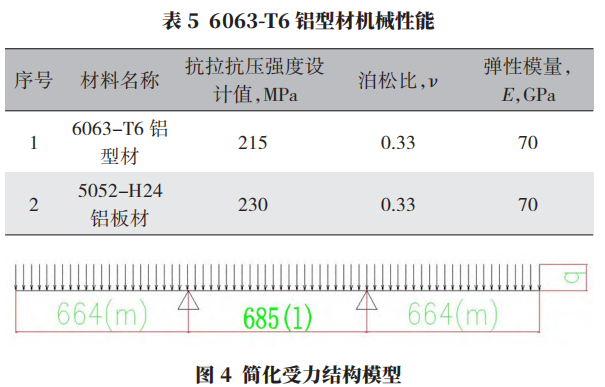

3.2 Kuwerengera Kupsinjika Kwambiri

Kutenga chigawo chofunikira chonyamula katundu, mtandawo, monga chinthu, kupanikizika kwakukulu kumawerengedwa. Kulemera kwake ndi 1.5 t, ndipo mtandawo umapangidwa ndi 6063-T6 aluminiyamu alloy profile ndi makina opangira monga momwe tawonetsera mu Table 5. Mtsinjewo umakhala wosavuta ngati mawonekedwe a cantilever kuti awerengere mphamvu, monga momwe tawonetsera pa Chithunzi 4.

Kutenga 344mm span mtanda, katundu woponderezedwa pamtengowo amawerengedwa ngati F = 3757 N kutengera 4.5t, yomwe ili katatu kuchuluka kwa static katundu. q=F/L

kumene q ndi kupsinjika kwamkati kwa mtengo pansi pa katundu, N / mm; F ndi katundu wonyamulidwa ndi mtengo, wowerengedwa kutengera nthawi za 3 kuchuluka kwa static, komwe ndi 4.5 t; L ndiye kutalika kwa mtengo, mm.

Chifukwa chake, kupsinjika kwamkati q ndi:

Njira yowerengera stress ndi motere:

Nthawi yabwino kwambiri ndi:

Kutenga mtengo wokwanira wa mphindi, M=274283 N·mm, kupanikizika kwakukulu σ=M/(1.05×w)=18.78 MPa, ndi kupanikizika kwakukulu kwa σ<215 MPa, zomwe zimakwaniritsa zofunikira.

3.3 Kulumikizana Makhalidwe a Zigawo Zosiyanasiyana

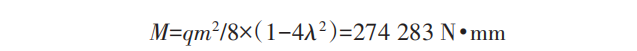

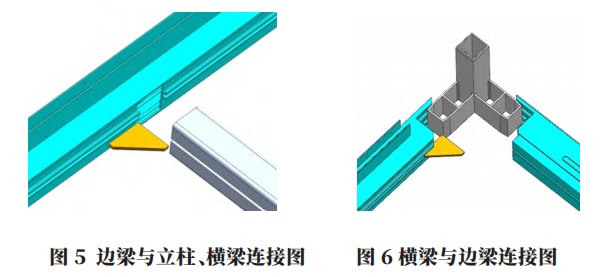

Aluminiyamu aloyi ndi osauka kuwotcherera katundu, ndi kuwotcherera mfundo mphamvu yake ndi 60% chabe za m'munsi mphamvu zakuthupi. Chifukwa cha kuphimba kwa Al2O3 pamwamba pa aluminiyumu alloy pamwamba, malo osungunuka a Al2O3 ndi apamwamba, pamene kusungunuka kwa aluminiyumu kumakhala kochepa. Pamene zitsulo zotayidwa welded, Al2O3 pamwamba ayenera kusweka mwamsanga kuchita kuwotcherera. Pa nthawi yomweyo, zotsalira za Al2O3 adzakhala mu njira zotayidwa aloyi, zimakhudza zotayidwa aloyi dongosolo ndi kuchepetsa mphamvu ya zotayidwa aloyi kuwotcherera mfundo. Chifukwa chake, popanga chidebe chonse cha aluminiyamu, izi zimaganiziridwa bwino. Kuwotcherera ndiye njira yayikulu yoyikira, ndipo zigawo zazikulu zonyamula katundu zimalumikizidwa ndi mabawuti. Malumikizidwe monga ma riveting ndi ma dovetail akuwonetsedwa pazithunzi 5 ndi 6.

Kapangidwe kake kabokosi ka aluminiyamu kamene kamakhala ndi mizati yopingasa, mizati yowongoka, mizati yam'mbali, ndi zitsulo zam'mphepete zomwe zimalumikizana wina ndi mnzake. Pali malo anayi olumikizirana pakati pa mtengo uliwonse wopingasa ndi mzati woyima. Malo olumikiziranawo amakhala ndi ma serrated gaskets kuti azitha kumana ndi m'mphepete mwachitsulo chopingasa, kuteteza bwino kutsetsereka. Makona asanu ndi atatu amalumikizidwa makamaka ndi zoyika zachitsulo, zokhazikika ndi ma bolts ndi ma rivets odzitsekera okha, ndipo amalimbikitsidwa ndi mbale za 5mm triangular aluminiyamu zowotcherera mkati mwa bokosi kuti alimbikitse malo angodya mkati. Maonekedwe akunja a bokosi alibe kuwotcherera kapena kuwonekera polumikizira, kuonetsetsa mawonekedwe onse a bokosi.

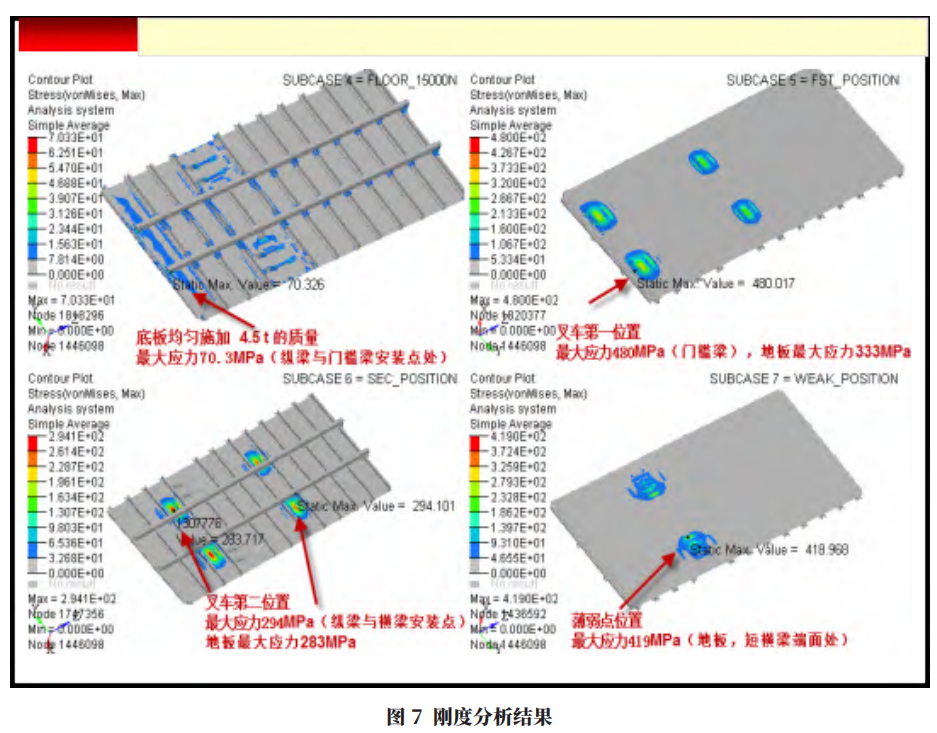

3.4 SE Synchronous Engineering Technology

Ukadaulo waukadaulo wa SE synchronous engineering umagwiritsidwa ntchito kuthana ndi zovuta zomwe zimayambitsidwa ndi kusokonekera kwakukulu kwa kukula kwa magawo omwe ali mubokosi la bokosi ndi zovuta zopeza zomwe zimayambitsa mipata ndi kulephera kwamphamvu. Kupyolera mu kusanthula kwa CAE (onani Chithunzi 7-8), kusanthula kofananitsa kumachitidwa ndi matupi opangidwa ndi chitsulo kuti ayang'ane mphamvu zonse ndi kuuma kwa bokosi la bokosi, kupeza mfundo zofooka, ndikuchitapo kanthu kuti akwaniritse ndi kukonza ndondomeko yokonza bwino.

4.Lightweighting Effect of Aluminium Alloy Box Truck

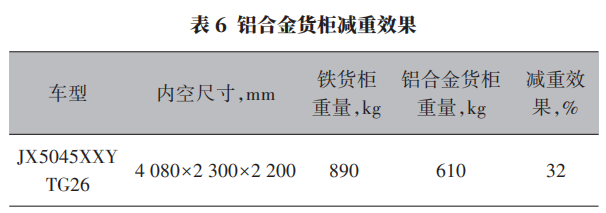

Kuphatikiza pa bokosilo, ma aloyi a aluminiyumu angagwiritsidwe ntchito m'malo mwa zitsulo zamitundu yosiyanasiyana yamagalimoto amtundu wa bokosi, monga alonda amatope, alonda akumbuyo, alonda am'mbali, zitseko za zitseko, mahinji a zitseko, ndi m'mphepete mwa apuloni akumbuyo, ndikuchepetsa kulemera kwa 30% mpaka 40% pagawo lonyamula katundu. Kuchepetsa kulemera kwa chidebe chonyamula katundu cha 4080mm×2300mm×2200mm chopanda kanthu chikuwonetsedwa mu Table 6. Izi zimathetsa mavuto a kulemera kwakukulu, kusagwirizana ndi zilengezo, ndi kuopsa kwa kayendetsedwe ka katundu wamtundu wopangidwa ndi chitsulo.

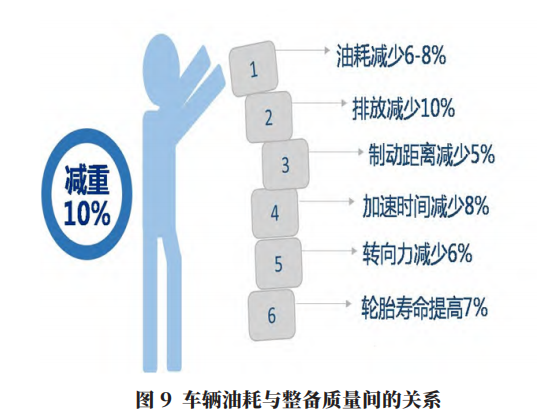

Posintha zitsulo zamtundu wa aluminiyamu pazigawo zamagalimoto, sizongowonjezera zopepuka zopepuka, komanso zimathandizira pakupulumutsa mafuta, kuchepetsa utsi, komanso kuyendetsa bwino galimoto. Pakalipano, pali malingaliro osiyanasiyana pa zopereka zopepuka kuti ziwongolere mafuta. Zotsatira za kafukufuku wa International Aluminium Institute zikuwonetsedwa mu Chithunzi 9. Kuchepetsa kulikonse kwa 10% pa kulemera kwa galimoto kungachepetse kugwiritsa ntchito mafuta ndi 6% mpaka 8%. Kutengera ziwerengero zapakhomo, kuchepetsa kulemera kwa galimoto yonyamula anthu ndi 100 kg kumatha kuchepetsa kugwiritsa ntchito mafuta ndi 0,4 L/100 km. Kuthandizira kopepuka pakupulumutsa mafuta kumatengera zotsatira zopezeka munjira zosiyanasiyana zofufuzira, kotero pali kusiyana kwina. Komabe, kuyatsa kwa magalimoto kumakhudza kwambiri kuchepetsa kugwiritsa ntchito mafuta.

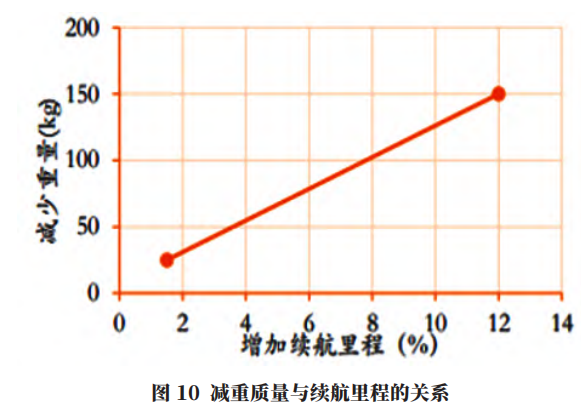

Kwa magalimoto amagetsi, mphamvu yopepuka imawonekera kwambiri. Pakadali pano, kuchuluka kwa mphamvu zamagalimoto amagetsi amagetsi ndikosiyana kwambiri ndi magalimoto amtundu wamafuta amadzimadzi. Kulemera kwa mphamvu zamagetsi (kuphatikizapo batri) zamagalimoto amagetsi nthawi zambiri zimakhala 20% mpaka 30% ya kulemera kwa galimoto. Nthawi yomweyo, kuthana ndi vuto la mabatire ndizovuta padziko lonse lapansi. Pasanakhale kupambana kwakukulu muukadaulo wapamwamba wa batri, kuwotcha ndi njira yabwino yosinthira magalimoto amagetsi amagetsi. Pakuchepetsa kulemera kwa 100 kg, magalimoto oyendetsa magetsi amatha kuwonjezereka ndi 6% mpaka 11% (ubale pakati pa kuchepetsa kulemera kwa thupi ndi maulendo oyendayenda akuwonetsedwa pa Chithunzi 10). Pakalipano, magalimoto oyendetsa magetsi osasunthika sangathe kukwaniritsa zosowa za anthu ambiri, koma kuchepetsa kulemera kwake kungathe kusintha kwambiri maulendo, kuchepetsa nkhawa komanso kupititsa patsogolo luso la wogwiritsa ntchito.

5.Mapeto

Kuphatikiza pa mapangidwe a aluminiyumu amtundu wa aluminium alloy box truck yomwe yatulutsidwa m'nkhaniyi, pali mitundu yosiyanasiyana ya magalimoto a bokosi, monga zisa za aluminiyamu, mbale za aluminiyamu, mafelemu a aluminiyamu + zikopa za aluminiyamu, ndi zotengera zonyamula katundu zosakanizidwa za iron-aluminium. Iwo ali ndi ubwino wa kulemera kwa kuwala, mphamvu zenizeni zenizeni, ndi kukana kwa dzimbiri bwino, ndipo safuna utoto wa electrophoretic kuti ateteze dzimbiri, kuchepetsa chilengedwe cha utoto wa electrophoretic. Galimoto ya aluminium alloy box box imathetsa mavuto olemera kwambiri, kusagwirizana ndi zilengezo, komanso kuopsa koyang'anira malo onyamula katundu opangidwa ndi chitsulo.

Extrusion ndi njira yofunikira yopangira ma aluminiyamu aloyi, ndipo mbiri ya aluminiyamu imakhala ndi makina abwino kwambiri, kotero kuuma kwa gawo la zigawo zake ndikokwera kwambiri. Chifukwa cha magawo osinthika, ma aluminiyamu aloyi amatha kukwaniritsa kuphatikiza kwazinthu zingapo, ndikupangitsa kuti ikhale chinthu chabwino pakuwunikira magalimoto. Komabe, kufalikira kwa ma aluminiyamu aloyi kumayang'anizana ndi zovuta monga kusakwanira kwa kapangidwe ka zipinda zonyamula katundu za aluminiyamu, zovuta zopanga ndi kuwotcherera, komanso mtengo wokwera ndi kukwezera zinthu zatsopano. Chifukwa chachikulu ndichakuti aloyi wa aluminiyumu amawononga ndalama zambiri kuposa chitsulo chisanayambe kukonzanso zachilengedwe zazitsulo zotayidwa.

Pomaliza, kuchuluka kwa ma aloyi a aluminiyamu m'magalimoto kudzakhala kokulirapo, ndipo kugwiritsidwa ntchito kwawo kukupitilirabe. M'machitidwe apano a kupulumutsa mphamvu, kuchepetsa utsi, ndi chitukuko cha mafakitale amagetsi atsopano, ndikumvetsetsa kwakuya kwa ma aluminiyamu aloyi ndi njira zothetsera mavuto ogwiritsira ntchito aluminum alloy application, zida za aluminium extrusion zidzagwiritsidwa ntchito kwambiri pakuwunikira magalimoto.

Adasinthidwa ndi May Jiang kuchokera ku MAT Aluminium

Nthawi yotumiza: Jan-12-2024