1. Makhalidwe a aluminiyamu ndi zotayidwa aloyi wapadera mwatsatanetsatane extrusion zipangizo

Mtundu uwu wa mankhwala ali ndi mawonekedwe apadera, woonda khoma makulidwe, kuwala unit kulemera, ndi okhwima kwambiri kulolerana zofunika. Zogulitsa zotere zimatchedwa aluminium alloy precision (kapena ultra-precision) mbiri (mapaipi), ndipo ukadaulo wopangira zinthu zotere umatchedwa kulondola. (kapena ultra-precision) extrusion.

Zinthu zazikulu za aluminiyamu alloy kulondola kwapadera (kapena kopitilira muyeso) ndi:

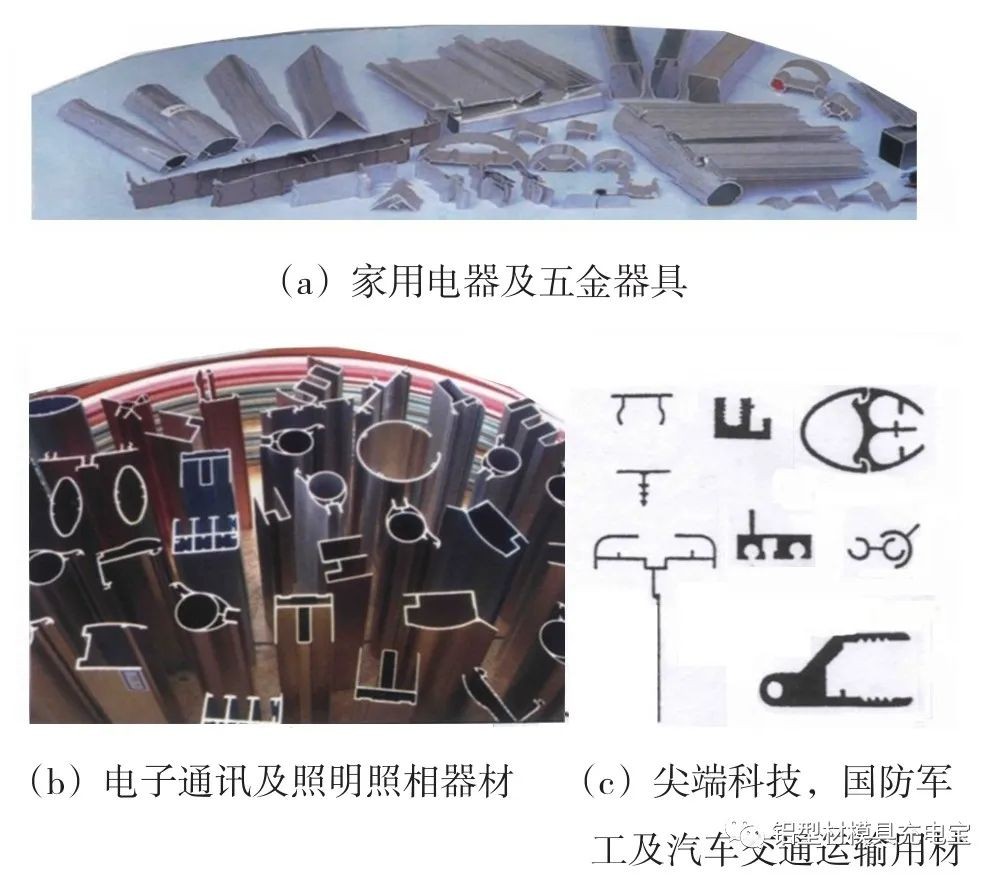

(1) Pali mitundu yambiri, magulu ang'onoang'ono, ndipo ambiri mwa iwo ndi zipangizo zapadera za extrusion, zomwe zimagwiritsidwa ntchito pafupifupi m'madera onse a moyo wa anthu komanso mbali zonse za moyo wa anthu, kuphatikizapo zinthu zonse za extrusion, monga mipope, mipiringidzo, mbiri ndi mawaya, kuphatikizapo aloyi osiyanasiyana ndi boma. Chifukwa cha magawo ake ang'onoang'ono, makulidwe a khoma laling'ono, kulemera kwake, ndi timagulu ting'onoting'ono, nthawi zambiri zimakhala zovuta kukonza kupanga.

(2) Mawonekedwe ovuta ndi ma contour apadera, makamaka opangidwa, osalala, otambalala, otambalala, mapiko, mano, ma porous profiles kapena mapaipi. Pamwamba pa voliyumu ya unit ndi yayikulu, ndipo ukadaulo wopanga ndi wovuta.

(3) Kugwiritsa ntchito kwakukulu, magwiridwe antchito apadera komanso zofunikira zogwirira ntchito. Kuti akwaniritse zofunikira zogwiritsira ntchito mankhwalawa, maiko ambiri a aloyi amasankhidwa, kuphimba pafupifupi ma aloyi onse kuyambira 1 × × × mpaka 8 × × mndandanda ndi mayiko ambiri amankhwala, okhala ndi luso lapamwamba.

(4) Maonekedwe okongola ndi makulidwe woonda khoma, zambiri zosakwana 0.5mm, ena kufika pafupifupi 0.1mm, kulemera kwa mita ndi magalamu ochepa chabe magalamu makumi, koma kutalika akhoza kufika mamita angapo, kapena mazana a mamita.

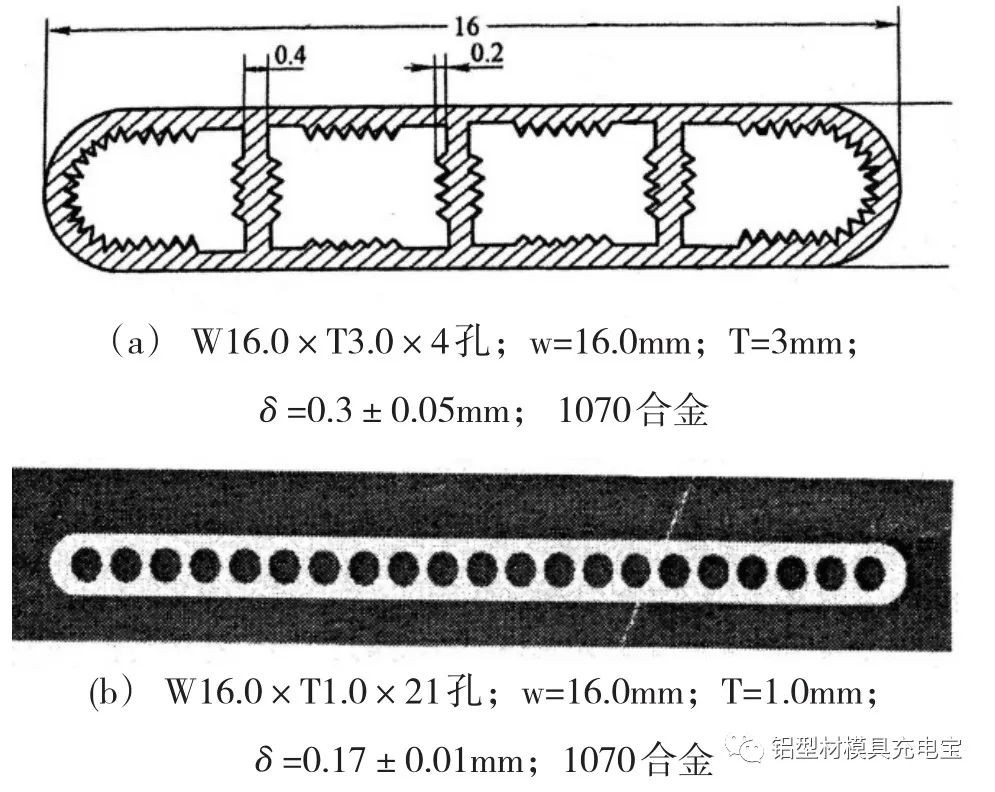

5) Kulondola kwazithunzi ndi zofunikira za kulekerera kwa geometric za gawoli ndizovuta kwambiri. Nthawi zambiri, kulolerana kwa ma profiles ang'onoang'ono a aluminiyamu mwatsatanetsatane ndizovuta kwambiri kuposa kulekerera kwapadera kwa JIS, GB, ndi ASTM. Kulekerera kwa makulidwe a khoma la mbiri yolondola ya aluminiyamu ya aloyi kumafunika kukhala pakati pa ± 0.04mm ndi 0.07mm, pomwe kulolerana kwa gawo la mbiri ya aluminiyamu yolondola kwambiri kumatha kukhala ± 0.01mm. Mwachitsanzo, kulemera kwa mbiri yolondola ya aluminiyamu yomwe imagwiritsidwa ntchito pa potentiometer ndi 30g/m, ndipo kulekerera kwa gawoli ndi ± 0.07mm. Kulekerera kwapang'onopang'ono kwa mbiri ya aluminiyamu yolondola yoluka ndi ± 0.04mm, kupatuka kwa ngodya kumakhala kosakwana 0.5 °, ndipo digiri yopindika ndi 0.83 × L. Chitsanzo china ndi chubu chapamwamba kwambiri chowonda kwambiri chagalimoto, chokhala ndi m'lifupi mwake 20mm, kutalika kwa 1.7mm, makulidwe a khoma la 0.17 ± 0.01mm, ndi mabowo 24, omwe ndi mbiri ya aluminiyamu yolondola kwambiri.

(6) Zili ndi luso lapamwamba kwambiri ndipo zimakhala zovuta kupanga, ndipo zimakhala ndi zofunikira zapadera za zipangizo zowonjezera, zida, ma billets ndi njira zopangira. Chithunzi 1 ndi chitsanzo cha gawo la mbiri yaying'ono yolondola ya aluminiyamu aloyi.

2. Gulu la aluminiyamu aloyi wapadera mwatsatanetsatane extrusion zipangizo

mwatsatanetsatane kapena kopitilira muyeso zotayidwa aloyi extrusions chimagwiritsidwa ntchito zida zamagetsi, zipangizo kulankhulana ndi kudula-m'mphepete sayansi, chitetezo dziko ndi asilikali makampani mwatsatanetsatane makina zida, ofooka zipangizo zamakono, zakuthambo, makampani nyukiliya, mphamvu ndi mphamvu, sitima zapamadzi ndi zombo, magalimoto ndi zida zoyendera , zipangizo zachipatala, zida hardware, kuyatsa, kujambula ndi zipangizo zamagetsi. Nthawi zambiri, ma aluminium alloy extrusions olondola kapena olondola kwambiri amatha kugawidwa m'magulu awiri molingana ndi mawonekedwe awo: gulu loyamba ndi mbiri zokhala ndi miyeso yaying'ono. Mbiri yamtunduwu imatchedwanso mawonekedwe ang'onoang'ono kapena mawonekedwe ang'onoang'ono. Kukula kwake konseko kumangokhala mamilimita ochepa, makulidwe ochepera a khoma ndi osakwana 0.5mm, ndipo kulemera kwake ndi magalamu angapo mpaka makumi a magalamu pa mita. Chifukwa cha kukula kwawo kochepa, kulolerana kolimba kumafunika pa iwo. Mwachitsanzo, kulolerana kwa magawo apakati ndi ochepera ± 0.05mm. Komanso, zofunika kuwongoka ndi torsion wa mankhwala extruded ndi okhwima kwambiri.

Mtundu winawo ndi mbiri zomwe sizili zazing'ono kwambiri mu kukula kwapang'onopang'ono koma zimafuna kulolerana kolimba kwambiri, kapena mbiri zomwe zimakhala ndi mawonekedwe ozungulira komanso makulidwe a khoma laling'ono ngakhale kukula kwa gawoli ndi lalikulu. Chithunzi 2 chikuwonetsa chubu chopangidwa mwapadera (aluminiyamu yoyera yamafakitale) yotulutsidwa ndi kampani yaku Japan pa makina osindikizira a 16.3MN opingasa a hydraulic okhala ndi chogawanika chapadera chopangira chowongolera mpweya wamagalimoto. Kuvuta kwa extrusion kupanga mawonekedwe amtundu uwu sikuchepera kuposa mtundu wakale wa mbiri yaying'ono kwambiri. Ma profayilo owonjezera okhala ndi gawo lalikulu komanso zofunikira zololera zokhwima sizimangofunika luso laukadaulo wamapangidwe a nkhungu, komanso zimafunikira ukadaulo wokhwima wowongolera ntchito yonse yopangira kuchokera kulibe kanthu mpaka kumaliza.

Kuyambira kumayambiriro kwa zaka za m'ma 1980, chifukwa cha kugwiritsa ntchito ukadaulo wa Conform mosalekeza waukadaulo komanso chitukuko chaukadaulo wamafakitale, kutulutsa kwambiri kochepa komanso kopitilira muyeso kwakula mwachangu. Komabe, chifukwa chazifukwa zosiyanasiyana monga kuchepa kwa zida, zofunikira zamtundu wazinthu, komanso kupita patsogolo kwaukadaulo wa extrusion, kupanga mbiri yaying'ono pazida wamba za extrusion kumakhalabe ndi gawo lalikulu. Chithunzi 2 chikusonyeza mwatsatanetsatane mbiri za extrusion wa ochiritsira kugawanika kufa. Moyo wa nkhungu (makamaka mphamvu ndi kuvala kukana kwa shunt mlatho ndi nkhungu pachimake) ndi kutuluka kwa zinthu panthawi ya extrusion kumakhala zinthu zazikulu zomwe zimakhudza kupanga kwake. Ichi ndi chifukwa pamene extruding mbiri, kukula kwa nkhungu pachimake ndi ang'onoang'ono ndi mawonekedwe ndi zovuta, ndi mphamvu ndi kuvala kukana ndi zinthu zofunika zimakhudza moyo wa nkhungu, moyo nkhungu zimakhudza mwachindunji mtengo kupanga. Kumbali inayi, mbiri zambiri zolondola zimakhala ndi makoma owonda komanso mawonekedwe ovuta, ndipo kutuluka kwa zinthu panthawi ya extrusion kumakhudza mwachindunji mawonekedwe ndi kulondola kwazithunzi.

Pofuna kupewa filimu ya okusayidi ndi mafuta pamwamba pa billet kuti asalowe mu mankhwala ndikuonetsetsa kuti yunifolomu ndi khalidwe lodalirika la mankhwala, billet imatenthedwa mpaka kutentha kwapadera kungathe kupukuta pamaso pa extrusion (yotchedwa hot peeling), ndiyeno mwamsanga kuika mu mbiya ya extrusion kwa extrusion. Pa nthawi yomweyo, ndi extruded gasket ayenera kukhala woyera kuteteza mafuta ndi dothi kutsatira gasket pa ndondomeko kuchotsa mavuto owonjezera pambuyo extrusion ndi khazikitsa gasket mu extrusion lotsatira.

Malinga ndi gawo laling'ono lolondola ndi mawonekedwe ndi kulolerana kwa malo, ma aluminium alloy extrusion mwapadera angagawidwe mwatsatanetsatane mbiri ya aluminiyamu ya aloyi ndi mbiri yaying'ono (yaing'ono) yapamwamba kwambiri ya aluminiyamu ya aloyi. Ambiri, kulondola kwake kuposa muyezo dziko (monga GB, JIS, ASTM, etc.) kopitilira muyeso-mkulu mwatsatanetsatane amatchedwa wapadera mwatsatanetsatane zotayidwa aloyi mbiri Mwachitsanzo, kulolerana dimensional pamwamba ± 0.1mm, kulolerana khoma makulidwe a pamwamba wosweka ndi mkati ± 0.05mm ~ ± 0.03mm mbiri.

Pamene kulondola kwake ndi kuwirikiza kawiri dziko muyezo kopitilira muyeso-mkulu mwatsatanetsatane, amatchedwa yaing'ono (yaing'ono) ultra-mkulu mwatsatanetsatane aloyi aloyi mbiri, monga kulolerana mawonekedwe ± 0.09mm, khoma makulidwe kulolerana ± 0.03mm ~ ± 0.01mm kwa mbiri yaing'ono (yaing'ono) kapena chitoliro.

3. Chiyembekezo cha chitukuko cha aluminiyamu ndi aluminiyamu aloyi wapadera mwatsatanetsatane extrusion zipangizo

Mu 2017, kupanga ndi malonda a zotayidwa processing zipangizo mu dziko kuposa 6000kt/a, amene kupanga ndi malonda a zotayidwa ndi zotayidwa aloyi extrusion zipangizo kuposa 25000kt/a, mlandu oposa 40% ya kupanga okwana ndi malonda a aluminiyamu. Aluminiyamu extruded sing'anga mipiringidzo amawerengera 90%, amene mbiri ambiri ndi mipiringidzo ndi ang'onoang'ono ndi sing'anga-kakulidwe mbiri zomangamanga boma mlandu oposa 80% ya bala, mbiri yaikulu ndi sing'anga-kakulidwe ndi mbiri yapadera wapadera ndi mipiringidzo nkhani za 15% yokha. The chitoliro nkhani za 8% ya zotayidwa aloyi extruded zakuthupi, pamene chitoliro zooneka ndi wapadera chitoliro chifukwa cha 20% okha chitoliro. Zitha kuwonedwa kuchokera pamwambapa kuti kupanga kwakukulu ndi kugulitsa kwa aluminiyamu ndi zitsulo zotayidwa aloyi extrusion ndipo zomwe zimagwiritsidwa ntchito kwambiri ndizojambula zazing'ono komanso zapakatikati, mbiri yakale ndi mipiringidzo ndi mapaipi. Ndipo mbiri yapadera, mipiringidzo ndi mapaipi amangowerengera pafupifupi 15%, zizindikiro zazikulu za zinthu zoterezi ndi: ndi ntchito zapadera kapena ntchito; Wodzipereka ku cholinga china; Kukhala ndi kukula kwakukulu kapena kochepa; Ndi kulondola kwapamwamba kwambiri kapena zofunikira zapamtunda. Choncho, mitundu yosiyanasiyana ndi yochulukirapo ndipo mtandawo ndi wochepa, kufunikira kowonjezera njira zapadera kapena kuwonjezera zida ndi zida zapadera, kupanga kumakhala kovuta komanso luso lapamwamba, mtengo wopangira umawonjezeka ndipo mtengo wowonjezera ukuwonjezeka.

Ndi kupita patsogolo kwa sayansi ndi umisiri ndi mosalekeza kusintha kwa makhalidwe a anthu, apamwamba ndi apamwamba zofunika akhala anaika patsogolo kwa linanena bungwe, khalidwe ndi zosiyanasiyana zotayidwa ndi zotayidwa aloyi extrusion mankhwala, makamaka m'zaka zaposachedwapa, zikamera wa mankhwala personalization walimbikitsa chitukuko cha mbiri yapadera ndi mipope ndi makhalidwe payekha ndi ntchito yeniyeni.

Mbiri yolondola kwambiri imagwiritsidwa ntchito kwambiri pazida zamagetsi, mauthenga, positi ndi zida zotumizira mauthenga, makina olondola, zida zolondola, zida zofooka zamakono, zakuthambo, sitima zapamadzi za nyukiliya ndi zombo, makampani oyendetsa magalimoto ndi madera ena ang'onoang'ono, khoma lochepa thupi, kukula kwa gawo la magawo olondola kwambiri. Kawirikawiri zofunika kulolerana ndi okhwima kwambiri, mwachitsanzo, gawo autilaini kukula kulolerana ndi zosakwana ± 0.10mm, khoma makulidwe kulolerana ndi zosakwana ± 0.05mm. Komanso, flatness, kupindika ndi mawonekedwe ena ndi malo tolerances wa mankhwala extruded ndi okhwima kwambiri. Komanso, mu ndondomeko extrusion wapadera kopitilira muyeso-mwatsatanetsatane zotayidwa aloyi mbiri, zipangizo, nkhungu, ndondomeko ndi zofunika kwambiri okhwima. Chifukwa cha kukula mofulumira makampani amakono, odula-m'mphepete chitetezo dziko ndi kafukufuku wa sayansi ndi ntchito zina ndi kusintha kwa digiri ya makonda, chiwerengero, zosiyanasiyana ndi khalidwe laing'ono kopitilira muyeso-mwatsatanetsatane mbiri zikuchulukirachulukira, ngakhale m'zaka zaposachedwapa, wapanga ndi opangidwa zambiri apamwamba ang'onoang'ono kopitilira muyeso zotayidwa aloyi mbiri, koma sangathe kukwaniritsa zosowa makamaka za zipangizo zoweta, pali kusiyana pakati pa zipangizo zamakono zoweta. ang'onoang'ono ultra-precision aluminium alloy profiles ndi mlingo wapamwamba wapadziko lonse lapansi, womwe sungathe kukwaniritsa zofuna za msika wapakhomo ndi wakunja ndipo uyenera kugwidwa.

4. Mapeto

Aluminiyamu ndi zitsulo zotayidwa aloyi wapadera mwatsatanetsatane extrusion (mbiri ndi mipope) ndi mtundu wa mawonekedwe ovuta, woonda khoma makulidwe, kulolerana dimensional ndi mawonekedwe ndi malo olondola amafuna kwambiri, okhutira mkulu luso, kupanga zovuta za mkulu, zipangizo zabwino, ndi chuma dziko ndi chitetezo dziko chofunika kwambiri zipangizo kiyi, osiyanasiyana kwambiri ntchito, akulonjeza chuma chiyembekezero chitukuko. Kupanga kwa mankhwalawa kuli ndi zofunikira zapadera za billet, zida zogwiritsira ntchito zida ndi extrusion ndi njira yotulutsira, ndipo mndandanda wazovuta zazikulu zaukadaulo ziyenera kuthetsedwa kuti mupeze zinthu zabwino kwambiri m'magulu.

Adasinthidwa ndi May Jiang kuchokera ku MAT Aluminium

Nthawi yotumiza: Apr-07-2024