1 Mawu Oyamba

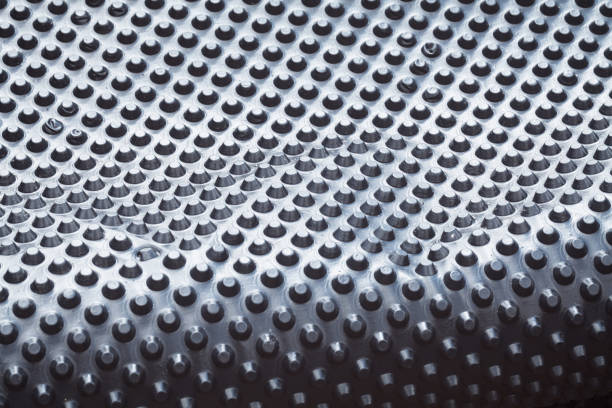

Ndi chitukuko chofulumira cha makampani a aluminiyamu ndi kuwonjezeka kosalekeza kwa matani a aluminium extrusion makina, teknoloji ya porous nkhungu aluminium extrusion yatulukira. Porous nkhungu zotayidwa extrusion bwino kwambiri kupanga dzuwa extrusion komanso amaika amafuna apamwamba luso pa nkhungu kapangidwe ndi extrusion njira.

2 Njira ya Extrusion

Mphamvu ya extrusion ndondomeko pa kupanga dzuwa porous nkhungu zotayidwa extrusion makamaka zimaonekera mu ulamuliro wa mbali zitatu: akusowekapo kutentha, nkhungu kutentha, ndi kutuluka kutentha.

2.1 Kutentha Kopanda kanthu

Uniform akusowekapo kutentha zimakhudza kwambiri linanena bungwe extrusion. Pakupanga kwenikweni, makina otulutsa omwe amatha kusinthika pamtunda nthawi zambiri amatenthedwa pogwiritsa ntchito ng'anjo zopanda kanthu. Ming'anjo yopanda kanthu imapereka kutentha kofananirako komanso kopanda kanthu kokhala ndi zinthu zabwino zotchinjiriza. Kuonjezera apo, pofuna kuonetsetsa kuti zikuyenda bwino, njira ya "kutentha kochepa ndi kuthamanga kwambiri" nthawi zambiri imagwiritsidwa ntchito. Pankhaniyi, kutentha opanda kanthu ndi kutentha kutuluka kuyenera kufanana kwambiri ndi liwiro la extrusion, ndi zoikamo poganizira kusintha kwa kuthamanga kwa extrusion ndi chikhalidwe cha malo opanda kanthu. Kutentha kopanda kanthu kumadalira momwe zinthu zimapangidwira, koma monga chitsogozo, pobowola nkhungu, kutentha kopanda kanthu kumasungidwa pakati pa 420-450 ° C, ndi kufa kwaphwando kumayikidwa pamwamba pang'ono ndi 10-20 ° C poyerekeza ndi kugawanika kumafa.

2.2 Kutentha kwa Mold

Kutengera zomwe zidachitika pamalowo, kutentha kwa nkhungu kuyenera kusungidwa pakati pa 420-450 ° C. Kutentha kwambiri nthawi kungayambitse kukokoloka kwa nkhungu panthawi yogwira ntchito. Komanso, kuyika nkhungu moyenera pakuwotha ndikofunikira. Zomwe zimapangidwira zisamangidwe moyandikana kwambiri, ndikusiya malo pakati pawo. Kuletsa kutuluka kwa mpweya wa ng'anjo ya nkhungu kapena kuyika kosayenera kungayambitse kutentha kosiyana ndi kutulutsa kosagwirizana.

3 Zinthu Zoumba

Mapangidwe a nkhungu, kukonza nkhungu, ndi kukonza nkhungu ndizofunikira kwambiri pakupanga mawonekedwe amtundu wa extrusion ndipo zimakhudza mwachindunji mtundu wa chinthu, kulondola kwa mawonekedwe, komanso kupanga bwino. Kuchokera muzochita zopanga ndikugawana zokumana nazo pamapangidwe a nkhungu, tiyeni tiwunike mbali izi.

3.1 Mapangidwe a Mold

Nkhungu ndiye maziko a mapangidwe azinthu ndipo amatenga gawo lofunikira pakuzindikira mawonekedwe, kulondola kwapang'onopang'ono, mawonekedwe apamwamba, komanso zinthu zakuthupi za chinthucho. Kwa mbiri ya porous nkhungu yokhala ndi zofunikira zapamwamba, kuwongolera pamwamba kungathe kutheka pochepetsa kuchuluka kwa dzenje lopatukira ndikukulitsa kuyika kwa milatho yopatukana kuti mupewe kukongoletsa kwakukulu kwambiri. Kuonjezera apo, pakufa kwa lathyathyathya, kugwiritsa ntchito mazenera obwerera kumbuyo kungawonetsetse kuti zitsulo zofanana zimalowa m'mabowo.

3.2 Kukonza nkhungu

Pakukonza nkhungu, kuchepetsa kukana kwachitsulo kumayenda pamilatho ndikofunikira. Kupukuta milatho yopatukirako kumatsimikizira kulondola kwa malo a mlatho wopatukirapo komanso kumathandiza kukwaniritsa zitsulo zofanana. Kwa ma profiles omwe ali ndi zofunikira zapamwamba, monga ma solar panel, ganizirani kukulitsa kutalika kwa chipinda chowotcherera kapena kugwiritsa ntchito njira yachiwiri yowotcherera kuti muwonetsetse zotsatira zabwino zowotcherera.

3.3 Kusamalira Nkhungu

Kusamalira nkhungu nthawi zonse nkofunikanso. Kupukuta nkhungu ndikukhazikitsa kukonza kwa nitrogenization kumatha kuletsa zovuta monga kuuma kosagwirizana m'malo ogwirira ntchito a nkhungu.

4 Ubwino Wopanda kanthu

Ubwino wa chinthu chopanda kanthu umakhudza kwambiri mtundu wa chinthu, kutulutsa bwino, komanso kuwonongeka kwa nkhungu. Zosamveka bwino zimatha kubweretsa zovuta zabwino monga ma grooves, kusinthika pambuyo pa okosijeni, komanso kuchepa kwa nkhungu. Khalidwe lopanda kanthu limaphatikizapo kapangidwe koyenera komanso kufanana kwa zinthu, zomwe zimakhudza mwachindunji kutulutsa kwakunja ndi mawonekedwe apamwamba.

4.1 Kusintha kwa Mapangidwe

Kutengera mawonekedwe a solar panel monga mwachitsanzo, kasinthidwe koyenera kwa Si, Mg, ndi Fe mu aloyi yapadera ya 6063 ya porous mold extrusion ndikofunikira kuti mukwaniritse mawonekedwe abwino popanda kuwononga makina. Chiwerengero chonse ndi gawo la Si ndi Mg ndizofunikira, ndipo kutengera zomwe zachitika kwa nthawi yayitali, kusunga Si + Mg mumitundu ya 0.82-0.90% ndikoyenera kupeza mtundu womwe mukufuna.

Pofufuza zotsalira zosagwirizana ndi ma solar panels, zidapezeka kuti kufufuza zinthu ndi zonyansa zinali zosakhazikika kapena zopitirira malire, zomwe zimakhudza kwambiri khalidwe lapamwamba. Kuwonjezera zinthu pa alloying mu malo osungunula ayenera kuchitidwa mosamala kupewa kusakhazikika kapena kuchulukira kwa zinthu kufufuza. M'magulu a zinyalala zamafakitale, zinyalala zotulutsa zinyalala zimaphatikizapo zinyalala zoyambira monga zodula ndi zoyambira, zinyalala zachiwiri zimaphatikizapo zinyalala zomwe zachotsedwa pambuyo pa ntchito monga makutidwe ndi okosijeni ndi zokutira zaufa, ndipo mbiri zotsekemera zotentha zimagawidwa ngati zinyalala zapamwamba. Ma profiles oxidized ayenera kugwiritsa ntchito mwapadera opanda kanthu, ndipo nthawi zambiri palibe zinyalala zomwe zidzawonjezedwe ngati zida zokwanira.

4.2 Njira Yopanga Zinthu Zopanda kanthu

Kuti mupeze zosoweka zapamwamba kwambiri, kutsata mosamalitsa zofunikira pakutsuka kwa nayitrogeni komanso nthawi yokhazikika ya aluminiyamu ndikofunikira. Ma alloying amawonjezedwa mu mawonekedwe a block, ndipo kusakaniza kokwanira kumagwiritsidwa ntchito kuti ifulumizitse kusungunuka kwawo. Kusakaniza koyenera kumalepheretsa mapangidwe amtundu wapamwamba kwambiri wa zinthu za alloy.

Mapeto

Ma aluminiyamu aloyi amagwiritsidwa ntchito kwambiri m'magalimoto amagetsi atsopano, omwe amagwiritsidwa ntchito m'magawo am'mapangidwe ndi magawo monga thupi, injini, ndi mawilo. Kuchulukirachulukira kwa ma aloyi a aluminiyumu m'makampani amagalimoto kumayendetsedwa ndi kufunikira kwa mphamvu zamagetsi komanso kukhazikika kwa chilengedwe, kuphatikiza kupita patsogolo kwaukadaulo wa aluminium alloy. Kwa ma profiles omwe ali ndi zofunikira zapamwamba kwambiri, monga ma tray a aluminiyamu a batri okhala ndi mabowo angapo amkati ndi zofuna zamakina apamwamba, kuwongolera bwino kwa porous mold extrusion ndikofunikira kuti makampani azichita bwino pakusintha kwamphamvu.

Adasinthidwa ndi May Jiang kuchokera ku MAT Aluminium

Nthawi yotumiza: May-30-2024