Pa extrusion ndondomeko zotayidwa aloyi extruded zipangizo, makamaka aluminiyamu mbiri, "pitting" chilema nthawi zambiri amapezeka pamwamba. Mawonetseredwe ake enieni amaphatikizapo zotupa zazing'ono zomwe zimakhala ndi makulidwe osiyanasiyana, matupi, ndi manja omveka bwino, ndi kumverera kwamphamvu. Pambuyo makutidwe ndi okosijeni kapena electrophoretic pamwamba mankhwala, iwo nthawi zambiri amawoneka ngati granules wakuda kumamatira pamwamba pa mankhwala.

Mu extrusion kupanga lalikulu-gawo mbiri, chilema izi ndi zambiri zimachitika chifukwa cha chikoka cha dongosolo ingot, extrusion kutentha, extrusion liwiro, nkhungu zovuta, etc. Ambiri a particles zabwino za zibowo zopunduka akhoza kuchotsedwa pa mbiri padziko pretreatment ndondomeko, makamaka alkali etching ndondomeko, pamene chiwerengero chochepa cha zazikulu-kakulidwe kakulidwe kakulidwe pa mawonekedwe olimba khalidwe, tinthu olimba maonekedwe a tinthu olimba pamwamba pa mawonekedwe olimba, tinthu mankhwala.

M'nyumba wamba khomo ndi zenera mbiri malonda, makasitomala zambiri kuvomereza zipatso zazing'ono pitted, koma mbiri mafakitale amene amafuna kutsindika ofanana katundu makina ndi ntchito kukongoletsa kapena kutsindika kwambiri ntchito kukongoletsa, makasitomala zambiri savomereza chilema, makamaka pitted zolakwika zomwe sizikugwirizana ndi mtundu wosiyana wa maziko.

Pofuna kusanthula mapangidwe limagwirira a akhakula particles, morphology ndi zikuchokera malo chilema pansi osiyana aloyi nyimbo ndi extrusion njira anali kusanthula, ndi kusiyana kwa zolakwika ndi masanjidwewo anali poyerekeza. Yankho lololera lothetsera bwino tinthu tating'onoting'ono tidayikidwa patsogolo, ndipo mayeso adayesedwa.

Kuti muthane ndi vuto la ma pitting a mbiri, ndikofunikira kumvetsetsa njira yopangira zolakwika za pitting. Pa ndondomeko extrusion, zotayidwa kumamatira kufa ntchito lamba ndi chifukwa chachikulu pitting zilema padziko extruded zotayidwa zipangizo. Izi ndichifukwa choti kutulutsa kwa aluminiyamu kumachitika pa kutentha kwakukulu pafupifupi 450 ° C. Ngati zotsatira za kutentha kwa deformation ndi kutentha kwa mkangano zikuwonjezedwa, kutentha kwachitsulo kudzakhala kokwera pamene chituluka mu dzenje lakufa. Pamene mankhwala amatuluka mu dzenje lakufa, chifukwa cha kutentha kwakukulu, pali chodabwitsa cha aluminiyumu yomamatira pakati pa chitsulo ndi lamba wogwira ntchito nkhungu.

Mawonekedwe a mgwirizanowu nthawi zambiri ndi: kubwereza mobwerezabwereza - kung'amba - kugwirizanitsa - kung'amba kachiwiri, ndipo mankhwalawa amayenda patsogolo, zomwe zimapangitsa kuti pakhale maenje ang'onoang'ono pamtunda wa mankhwala.

Chodabwitsa ichi chomangirira chikugwirizana ndi zinthu monga mtundu wa ingot, mawonekedwe amtundu wa lamba wogwirira ntchito nkhungu, kutentha kwa extrusion, kuthamanga kwa extrusion, kuchuluka kwa mapindikidwe, ndi kukana kwachitsulo.

1 Zida zoyesera ndi njira

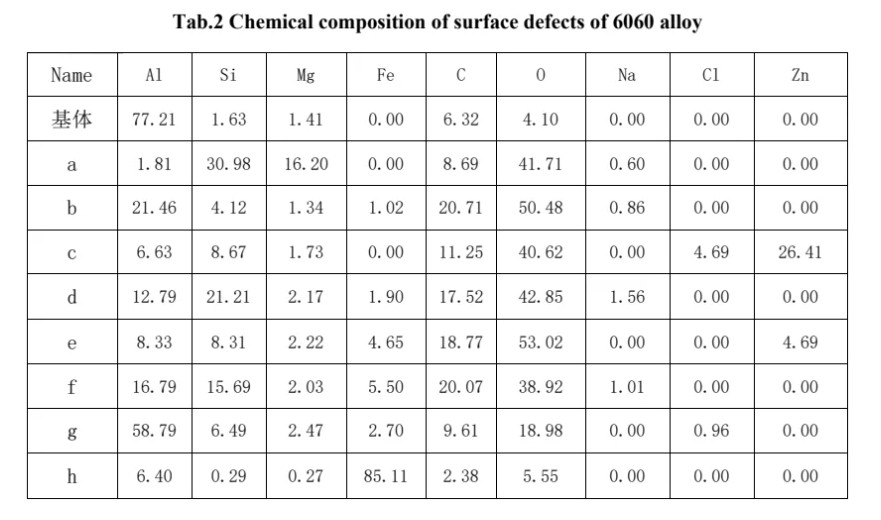

Kupyolera mu kafukufuku koyambirira, tinaphunzira kuti zinthu monga metallurgical chiyero, udindo nkhungu, extrusion ndondomeko, zosakaniza, ndi zinthu kupanga zingakhudze pamwamba roughened particles. Pakuyesa, ndodo ziwiri za alloy, 6005A ndi 6060, zidagwiritsidwa ntchito kutulutsa gawo lomwelo. Mapangidwe ndi kapangidwe ka magawo a tinthu tating'onoting'ono adawunikidwa kudzera mu spectrometer yowerengera molunjika ndi njira zodziwira za SEM, ndikuyerekeza ndi matrix ozungulira.

Pofuna kusiyanitsa momveka bwino morphology ya zolakwika ziwiri za pitted ndi particles, zimatanthauzidwa motere:

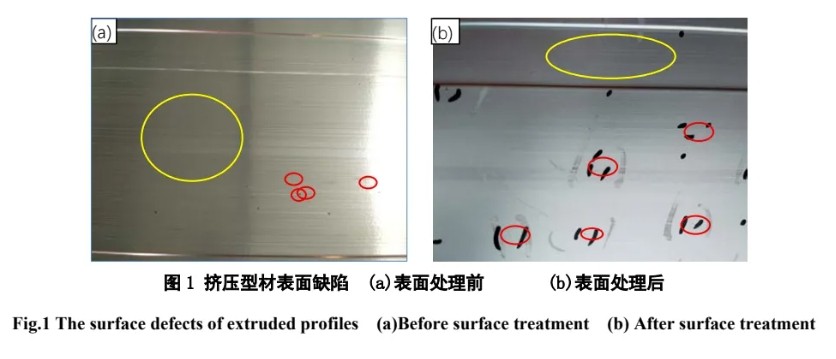

(1) Zowonongeka zokhala ndi zibowo kapena kukoka ndi mtundu wa cholakwika chomwe chimakhala ngati tadpole kapena chilema chowoneka pamwamba pa mbiri. Chilemacho chimayamba kuchokera pamzere woyambira ndikutha ndi chilemacho, ndikuwunjikana mu nyemba zachitsulo kumapeto kwa mzere woyambira. Kukula kwa chilemacho nthawi zambiri chimakhala 1-5mm, ndipo chimasanduka mdima wakuda pambuyo pa chithandizo cha okosijeni, chomwe chimakhudza mawonekedwe a mbiriyo, monga zikuwonetsedwa mubwalo lofiira pa Chithunzi 1.

(2) Tinthu tating'onoting'ono timatchedwanso nyemba zachitsulo kapena tinthu tating'onoting'ono ta adsorption. Pamwamba pa aluminiyumu alloy mbiri amamangiriridwa ndi ozungulira imvi-wakuda zitsulo zolimba particles ndipo ali ndi dongosolo lotayirira. Pali mitundu iwiri ya mbiri ya aluminiyamu alloy: omwe amatha kufafanizidwa ndi omwe sangathe kufufutidwa. Kukula kwake nthawi zambiri kumakhala kosakwana 0.5mm, ndipo kumakhala kovutirapo kukhudza. Kutsogolo kulibe zokanda. Pambuyo pa okosijeni, sizosiyana kwambiri ndi matrix, monga momwe tawonetsera mu bwalo lachikasu pa Chithunzi 1.

2 Zotsatira za mayeso ndi kusanthula

2.1 Zowonongeka zokoka pamwamba

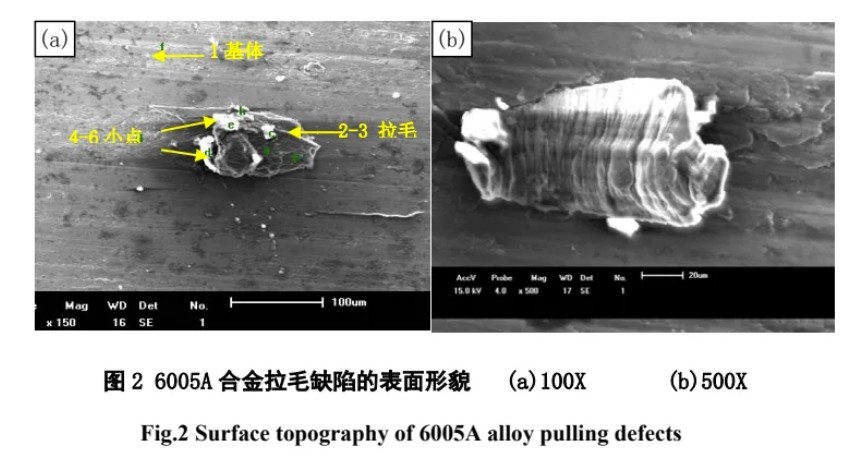

Chithunzi 2 chikuwonetsa kachitidwe ka microstructural kachilema chokoka pamwamba pa alloy 6005A. Pali zokopa zonga masitepe kutsogolo kwa kukoka, ndipo zimatha ndi timinofu tambirimbiri tambirimbiri. Pambuyo powonekera, pamwamba pake amabwerera mwakale. Malo a roughening chilema si yosalala kukhudza, ali lakuthwa kumverera kwa minga, ndipo amamatira kapena kudziunjikira pamwamba pa mbiri. Kupyolera mu mayeso a extrusion, adawona kuti kukoka morphology ya 6005A ndi 6060 extruded profiles ndi ofanana, ndipo mapeto a mchira wa mankhwala ndi oposa mutu; kusiyana kwake ndikuti kukula konsekoko kwa 6005A ndikocheperako ndipo kuya kwakuya kumachepa. Izi zitha kukhala zokhudzana ndi kusintha kwa kapangidwe ka aloyi, mawonekedwe a ndodo, ndi mawonekedwe a nkhungu. Kuwonedwa pansi pa 100X, pali zizindikiro zoonekeratu kutsogolo kwa malo okoka, omwe amatalikirana ndi njira yowonjezera, ndipo mawonekedwe a tinthu tating'onoting'ono tomaliza ndi osakhazikika. Pa 500X, kutsogolo kutsogolo kwa kukoka pamwamba kumakhala ndi masitepe ngati masitepe motsatira njira ya extrusion (kukula kwa chilemachi ndi pafupifupi 120 μm), ndipo pali zizindikiro zodziwikiratu pazitsulo za nodular kumapeto kwa mchira.

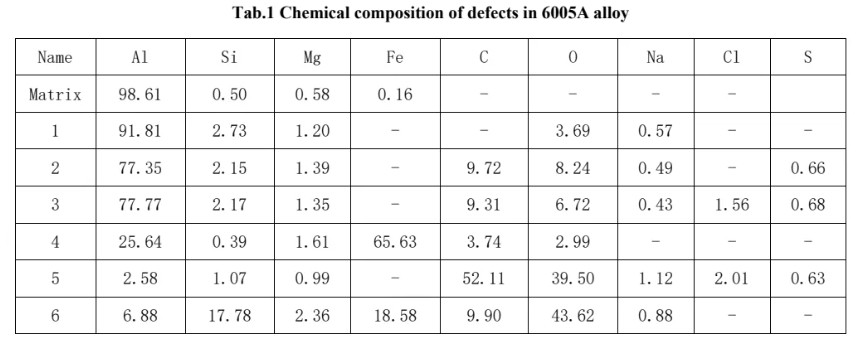

Pofuna kufufuza zomwe zimayambitsa kukoka, spectrometer yowerengera molunjika ndi EDX zinagwiritsidwa ntchito pofufuza chigawo cha malo olakwika ndi matrix a zigawo zitatu za alloy. Gulu 1 likuwonetsa zotsatira za mayeso a mbiri ya 6005A. Zotsatira za EDX zikuwonetsa kuti mawonekedwe a stacking malo a particles kukoka kwenikweni ndi ofanana ndi matrix. Kuphatikiza apo, tinthu tating'onoting'ono toyipa timaunjikana mkati ndi kuzungulira chilema chokoka, ndipo tinthu tazonyansa timakhala ndi C, O (kapena Cl), kapena Fe, Si, ndi S.

Kuwunika kwa roughening zolakwika za 6005A zabwino oxidized extruded mbiri zikusonyeza kuti kukoka particles ndi lalikulu kukula (1-5mm), pamwamba kwambiri zakhala zikuzunza m'miyoyo, ndipo pali sitepe-ngati zokopa kutsogolo gawo; Zomwe zili pafupi ndi matrix a Al, ndipo padzakhala magawo osiyanasiyana omwe ali ndi Fe, Si, C, ndi O omwe amagawidwa mozungulira. Zimasonyeza kuti kukoka mapangidwe limagwirira a aloyi atatu ndi chimodzimodzi.

Panthawi ya extrusion, kukangana kwachitsulo kumapangitsa kutentha kwa lamba wogwirira ntchito kukwera, kupanga "chosanjikiza chomata cha aluminiyamu" pamphepete mwa khomo lolowera lamba. Nthawi yomweyo, Si owonjezera ndi zinthu zina monga Mn ndi Cr mu aloyi ya aluminiyamu ndizosavuta kupanga njira zosinthira zolimba ndi Fe, zomwe zimalimbikitsa kupanga "zosanjikiza zomata za aluminiyumu" pakhomo la zone yogwirira ntchito.

Pamene zitsulo zikuyenda kutsogolo ndikugwedeza pa lamba wa ntchito, chinthu chobwerezabwereza cha kugwirizanitsa-kung'amba-kumangiriza-kumangiriza kumachitika pamalo enaake, kuchititsa kuti chitsulo chizipitirirabe pamwamba pa malo awa. Pamene particles kuwonjezeka kwa kukula, Iwo adzakokedwa kutali ndi loyenda mankhwala ndi kupanga zikande zizindikiro pa zitsulo pamwamba. Iwo adzakhala pa zitsulo pamwamba ndi kupanga kukoka particles kumapeto kwa zikande. Choncho, zikhoza kuganiziridwa kuti mapangidwe roughened particles makamaka zokhudzana ndi zotayidwa kumamatira ku nkhungu ntchito lamba. The heterogeneous magawo anagawira mozungulira angachokere mafuta mafuta, oxides kapena fumbi particles, komanso zonyansa anabweretsa akhakula pamwamba pa ingot.

Komabe, kuchuluka kwa zomwe zimakoka pazotsatira za 6005A ndizocheperako ndipo digiriyo ndiyopepuka. Kumbali imodzi, ndi chifukwa cha chamfering pa kutuluka kwa nkhungu ntchito lamba ndi kupukuta mosamala lamba ntchito kuchepetsa makulidwe a wosanjikiza aluminiyamu; Kumbali inayi, zimagwirizana ndi kuchuluka kwa Si.

Malinga ndi zotsatira zowerengera molunjika, zitha kuwoneka kuti kuwonjezera pa Si kuphatikiza ndi Mg Mg2Si, Si yotsalayo imawoneka ngati chinthu chosavuta.

2.2 Tinthu tating'onoting'ono pamtunda

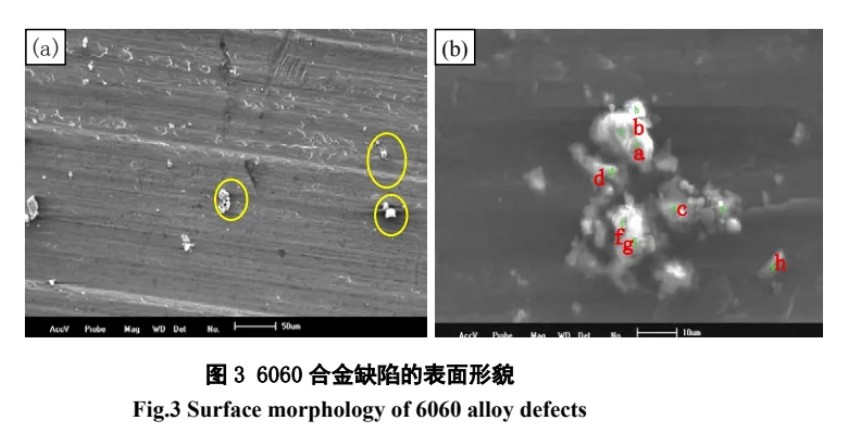

Poyang'aniridwa ndi mawonekedwe otsika kwambiri, tinthu tating'onoting'ono (≤0.5mm), sizosalala mpaka kukhudza, kukhala ndi malingaliro akuthwa, ndikumamatira pamwamba pa mbiriyo. Anawona pansi pa 100x, tinthu tating'onoting'ono tofalitsidwapo ndi anthu ambiri, ndipo pali tinthu tating'onoting'ono tomwe timayankhulidwapo ngakhale zitakhala kuti pali zingwe zokanga kapena ayi;

Pa 500X, ziribe kanthu kaya pali zoonekeratu ngati sitepe ngati zikanda pamwamba pa njira extrusion, particles ambiri akadali Ufumuyo, ndi tinthu kukula zosiyanasiyana. Kukula kwakukulu kwa tinthu ndi pafupifupi 15 μm, ndipo tinthu tating'onoting'ono tokhala ndi 5 μm.

Kupyolera mu kufufuza kwa 6060 alloy pamwamba particles ndi matrix osasinthika, tinthu tating'onoting'ono timapangidwa ndi O, C, Si, ndi Fe, ndipo zotayidwa ndizochepa kwambiri. Pafupifupi tinthu tating'onoting'ono tomwe timakhala ndi zinthu za O ndi C. Kapangidwe ka tinthu kalikonse ndi kosiyana pang'ono. Pakati pawo, tinthu tating'onoting'ono tating'ono ta 10 μm, zomwe ndi zapamwamba kwambiri kuposa matrix Si, Mg, ndi O; Mu c particles, Si, O, ndi Cl mwachiwonekere ndi apamwamba; Tinthu d ndi f ali ndi Si, O, ndi Na wapamwamba kwambiri; tinthu tating'onoting'ono timakhala ndi Si, Fe, ndi O; h tinthu tating'onoting'ono tomwe timakhala ndi Fe. Zotsatira za 6060 particles ndizofanana ndi izi, koma chifukwa Si ndi Fe zomwe zili mu 6060 zokha ndizochepa, zomwe zimagwirizana ndi Si ndi Fe zomwe zili pamwamba pa particles ndizochepa; C zomwe zili mu 6060 particles ndizochepa.

Tinthu tating'onoting'ono sitingakhale tinthu tating'ono ting'onoting'ono, koma titha kukhalanso ngati tinthu tating'ono tating'ono tambiri tokhala ndi mawonekedwe osiyanasiyana, ndipo kuchuluka kwa zinthu zosiyanasiyana m'tinthu tosiyanasiyana kumasiyana. Amakhulupirira kuti tinthu tating'onoting'ono timapangidwa ndi mitundu iwiri. Chimodzi ndi ma precipitates monga AlFeSi ndi elemental Si, omwe amachokera ku magawo osungunuka kwambiri osungunuka monga FeAl3 kapena AlFeSi(Mn) mu ingot, kapena magawo a precipitate panthawi ya extrusion. China ndi chotsatira chachilendo.

2.3 Zotsatira za roughness pamwamba pa ingot

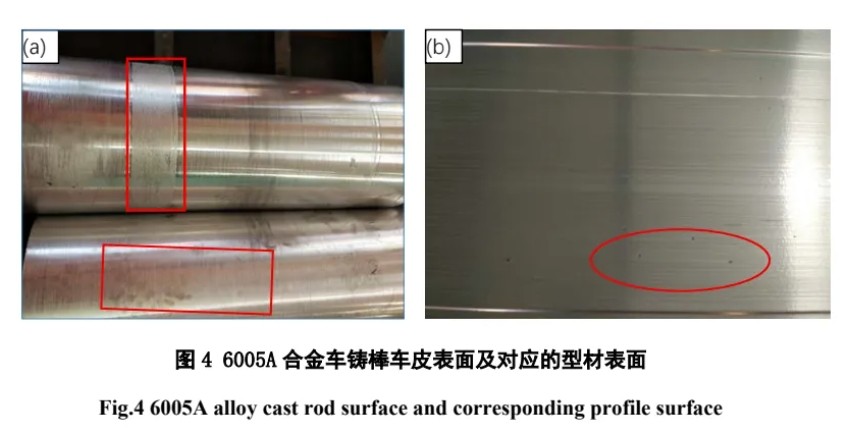

Pakuyesedwa, adapeza kuti kumbuyo kwa 6005A ndodo yachitsulo kunali kovuta komanso kodetsedwa ndi fumbi. Panali ndodo ziwiri zoponyedwa zokhala ndi zizindikiro zozama kwambiri zotembenuza m'malo am'deralo, zomwe zimafanana ndi kuwonjezeka kwakukulu kwa chiwerengero cha kukoka pambuyo pa extrusion, ndipo kukula kwa kukoka kamodzi kunali kokulirapo, monga momwe tawonetsera pa Chithunzi 7.

Ndodo ya 6005A ilibe lathe, kotero kuti kuuma kwapansi kumakhala kochepa ndipo chiwerengero cha kukoka kumachepetsedwa. Kuonjezera apo, popeza palibe madzi owonjezera odula omwe amamangiriridwa pazitsulo za ndodo, C zomwe zili mumagulu ofananira zimachepetsedwa. Zikutsimikiziridwa kuti kutembenuka kwa pamwamba pa ndodo yoponyedwa kumawonjezera kukoka ndi kupanga tinthu kumlingo wina.

3 Kukambitsirana

(1) Zigawo za kukoka zolakwika ndizofanana ndi za matrix. Ndi particles yachilendo, khungu lakale pamwamba pa ingot ndi zonyansa zina anasonkhana mu extrusion mbiya khoma kapena akufa m`dera nkhungu pa ndondomeko extrusion, amene anabweretsedwa kwa zitsulo pamwamba kapena zotayidwa wosanjikiza wa nkhungu ntchito lamba. Pamene mankhwalawo akuyenda patsogolo, ziwombankhanga zam'mwamba zimayambitsidwa, ndipo pamene mankhwalawo akuchulukana mpaka kukula kwake, amachotsedwa ndi mankhwala kuti apange kukoka. Pambuyo pa okosijeni, kukokako kunachita dzimbiri, ndipo chifukwa cha kukula kwake kwakukulu, panali zolakwika zonga dzenje pamenepo.

(2) Tinthu tating'onoting'ono nthawi zina timawoneka ngati tinthu tating'onoting'ono, ndipo nthawi zina timakhala mophatikizana. Mapangidwe awo mwachiwonekere ndi osiyana ndi a matrix, ndipo makamaka amakhala ndi O, C, Fe, ndi Si. Zina mwa tinthu tating'onoting'ono timayendetsedwa ndi O ndi C, ndipo tinthu tating'onoting'ono timayang'aniridwa ndi O, C, Fe, ndi Si. Choncho, zimaganiziridwa kuti particles pamwamba zimachokera ku magwero awiri: imodzi ndi precipitates monga AlFeSi ndi elemental Si, ndi zonyansa monga O ndi C zimamatiridwa pamwamba; China ndi chotsatira chachilendo. The particles ndi dzimbiri kutali pambuyo makutidwe ndi okosijeni. Chifukwa cha kukula kwawo kochepa, alibe kapena kukhudza pang'ono pamtunda.

(3) Tinthu tambiri C ndi O zinthu makamaka zimachokera mafuta mafuta, fumbi, nthaka, mpweya, etc. amamatira pamwamba pa ingot. Zigawo zazikulu za mafuta opaka mafuta ndi C, O, H, S, etc., ndipo chigawo chachikulu cha fumbi ndi nthaka ndi SiO2. The O zili pamwamba particles zambiri mkulu. Chifukwa tinthu tating'onoting'ono timatentha kwambiri mutangosiya lamba wogwirira ntchito, ndipo chifukwa cha malo akuluakulu enieni a tinthu tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono timatulutsa ma atomu a O mumlengalenga ndikuyambitsa oxidation pambuyo pokhudzana ndi mlengalenga, zomwe zimapangitsa kukhala ndi kuchuluka kwa O kuposa masanjidwewo.

(4) Fe, Si, etc. makamaka amachokera ku oxides, msinkhu wakale ndi magawo onyansa mu ingot (malo osungunuka kwambiri kapena gawo lachiwiri lomwe silinathetsedwe mokwanira ndi homogenization). Fe element imachokera ku Fe muzitsulo za aluminiyamu, kupanga magawo osungunuka kwambiri osungunuka monga FeAl3 kapena AlFeSi (Mn), omwe sangathe kusungunuka mu njira yolimba panthawi ya homogenization, kapena osatembenuzidwa mokwanira; Si ilipo mu matrix a aluminium mu mawonekedwe a Mg2Si kapena yankho lolimba la Si panthawi yoponya. Pa kutentha kwa extrusion ndondomeko ya ndodo yoponyedwa, owonjezera Si akhoza kuthamanga. Kusungunuka kwa Si mu aluminium ndi 0.48% pa 450 ° C ndi 0.8% (wt%) pa 500 ° C. Zochulukira za Si mu 6005 ndi pafupifupi 0.41%, ndipo mpweya wa Si ukhoza kukhala wophatikizana ndi mvula chifukwa cha kusinthasintha kwa ndende.

(5) Aluminiyamu kumamatira ku nkhungu yogwirira ntchito lamba ndiye chifukwa chachikulu chokoka. The extrusion die ndi malo otentha kwambiri komanso othamanga kwambiri. Kukangana kwachitsulo kumawonjezera kutentha kwa lamba wogwirira ntchito wa nkhungu, kupanga "chosanjikiza chomata cha aluminiyamu" pamphepete mwa khomo lolowera lamba.

Nthawi yomweyo, Si owonjezera ndi zinthu zina monga Mn ndi Cr mu aloyi ya aluminiyamu ndizosavuta kupanga njira zosinthira zolimba ndi Fe, zomwe zimalimbikitsa kupanga "zosanjikiza zomata za aluminiyumu" pakhomo la zone yogwirira ntchito. Chitsulo chomwe chikuyenda mu "zomata za aluminiyumu wosanjikiza" ndi cha kukangana kwamkati (kumeta ubweya mkati mwachitsulo). Chitsulo chimapunduka ndikuwumitsa chifukwa cha kukangana kwamkati, zomwe zimalimbikitsa chitsulo chapansi ndi nkhungu kumamatirana. Pa nthawi yomweyo, nkhungu ntchito lamba ndi olumala mu lipenga mawonekedwe chifukwa cha kupsyinjika, ndi zomata aluminiyamu wopangidwa ndi kudula m'mphepete mbali lamba ntchito kukhudzana ndi mbiri ndi ofanana ndi kudula m'mphepete mwa chida kutembenukira.

Mapangidwe a aluminiyamu yomata ndi njira yosinthira kukula ndi kukhetsa. Tinthu nthawi zonse kutulutsidwa ndi mbiri.Kumamatira pamwamba pa mbiri, kupanga kukoka zilema. Ngati imayenda molunjika kuchokera ku lamba wogwirira ntchito ndipo imakongoletsedwa nthawi yomweyo pamwamba pa mbiriyo, tinthu tating'onoting'ono tomwe timamatira pamwamba timatchedwa "adsorption particles". Ngati ena particles adzakhala wosweka ndi extruded zotayidwa aloyi, ena particles adzakhala n'kudziphatika pamwamba pa lamba ntchito podutsa ntchito lamba, kuchititsa zokopa padziko mbiri. Kumapeto kwa mchira ndi matrix a aluminiyamu osakanikirana. Pamene pali aluminiyumu yambiri yomwe imamatira pakati pa lamba wa ntchito (chomangiracho chimakhala cholimba), chidzakulitsa zokopa zapamtunda.

(6) Kuthamanga kwa extrusion kumakhudza kwambiri kukoka. Mphamvu ya extrusion liwiro. Pankhani ya aloyi ya 6005, kuthamanga kwa extrusion kumawonjezeka mkati mwa mayeso, kutentha kwa malo kumawonjezeka, ndipo kuchuluka kwa tinthu tating'onoting'ono tomwe timakoka kumawonjezeka ndikulemera kwambiri pamene mizere yamakina ikuwonjezeka. Liwiro la extrusion liyenera kukhala lokhazikika momwe mungathere kuti mupewe kusintha kwadzidzidzi kwa liwiro. Kuthamanga kwambiri kwa extrusion ndi kutentha kwapamwamba kwambiri kungayambitse mikangano yambiri komanso kukoka kwakukulu kwa tinthu. Njira yeniyeni ya mphamvu ya extrusion liwiro pa kukoka chodabwitsa amafuna kutsatira ndi kutsimikizira wotsatira.

(7) Ubwino wa pamwamba pa ndodo yoponyedwa ndi chinthu chofunika kwambiri chokhudza kukoka particles. Pamwamba pa ndodo yachitsulo ndi yovuta, yokhala ndi macheka, madontho a mafuta, fumbi, dzimbiri, ndi zina zotero, zomwe zimawonjezera chizolowezi chokoka particles.

4 Mapeto

(1) Kupangidwa kwa zolakwika zokoka kumagwirizana ndi matrix; kapangidwe ka tinthu tating'ono tating'ono tating'ono tating'ono tating'onoting'ono ta masanjidwewo, makamaka okhala ndi O, C, Fe, ndi Si.

(2) Kukoka kwa tinthu ting'onoting'ono kumachitika makamaka chifukwa cha aluminiyumu yomamatira ku lamba wogwirira ntchito. Zinthu zilizonse zomwe zimalimbikitsa aluminiyumu kumamatira ku lamba wogwirira ntchito ku nkhungu zingayambitse kusokonekera. Pamaziko owonetsetsa kuti ndodoyo ili yabwino, m'badwo wa tinthu tating'onoting'ono tating'ono tating'ono tating'ono tating'onoting'ono ta aloyi.

(3) Kuchiza koyenera kofanana ndi moto kumapindulitsa kuchepetsa kukoka pamwamba.

Nthawi yotumiza: Sep-10-2024