Ngati makina opangira ma extrusions sali momwe amayembekezeredwa, chidwi nthawi zambiri chimangoyang'ana pakupanga koyambirira kwa billet kapena mikhalidwe ya extrusion / ukalamba. Anthu ochepa amakayikira ngati homogenization palokha kungakhale vuto. M'malo mwake, gawo la homogenization ndilofunika kwambiri popanga ma extrusion apamwamba kwambiri. Kulephera kuwongolera bwino gawo la homogenization kungayambitse:

●Kuthamanga kwambiri

●Zowonongeka zina

●Sinthani mawonekedwe pambuyo anodizing

● Kuthamanga kwapansi kwa extrusion

● Kusagwira ntchito bwino kwa makina

Gawo la homogenization lili ndi zolinga ziwiri zazikulu: kuyenga chitsulo chokhala ndi intermetallic mankhwala, ndikugawanso magnesium (Mg) ndi silicon (Si). Poyang'ana microstructure ya billet isanayambe komanso itatha homogenization, munthu akhoza kudziwiratu ngati billet idzachita bwino panthawi ya extrusion.

Zotsatira za Billet Homogenization pa Kuwumitsa

Mu ma extrusions 6XXX, mphamvu zimachokera ku magawo a Mg- ndi Si-rich omwe amapangidwa akamakalamba. Kutha kupanga magawowa kumadalira kuyika zinthuzo kukhala njira yolimba ukalamba usanayambe. Kuti Mg ndi Si zikhale gawo la yankho lolimba, chitsulocho chiyenera kuzimitsidwa mofulumira kuchokera pamwamba pa 530 ° C. Pakutentha pamwamba pa mfundoyi, Mg ndi Si zimasungunuka kukhala aluminiyamu. Komabe, pa extrusion, zitsulo zimangokhala pamwamba pa kutentha kumeneku kwa nthawi yochepa. Kuonetsetsa kuti Mg ndi Si zonse zisungunuke, tinthu tating'ono ta Mg ndi Si tikuyenera kukhala tating'ono. Tsoka ilo, pakuponyedwa, Mg ndi Si amatsika ngati midadada yayikulu ya Mg₂Si (mkuyu 1a).

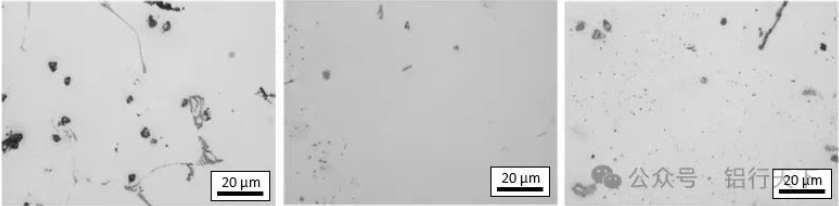

Kuzungulira kwa homogenization kwa 6060 billets ndi 560 °C kwa maola awiri. Panthawiyi, popeza billet imakhala pamwamba pa 530 ° C kwa nthawi yaitali, Mg₂Si imasungunuka. Ikazizira, imayambanso kugawa bwino kwambiri (mkuyu 1c). Ngati kutentha kwa homogenization sikuli kokwanira, kapena nthawi ndi yochepa kwambiri, tinthu tating'ono ta Mg₂Si tidzakhalabe. Izi zikachitika, yankho lolimba pambuyo pa extrusion limakhala ndi Mg ndi Si zochepa, zomwe zimapangitsa kuti zikhale zosatheka kupanga kachulukidwe kakang'ono ka kuuma kowumitsidwa-zomwe zimatsogolera kutsika kwamakina.

Chithunzi 1. Ma micrographs owoneka bwino a ma billets opukutidwa ndi 2% a HF-etched 6060: (a) ngati-cast, (b) opangidwa pang'ono, (c) opangidwa ndi homogenized.

Udindo wa Homogenization pa Iron-containing Intermetallics

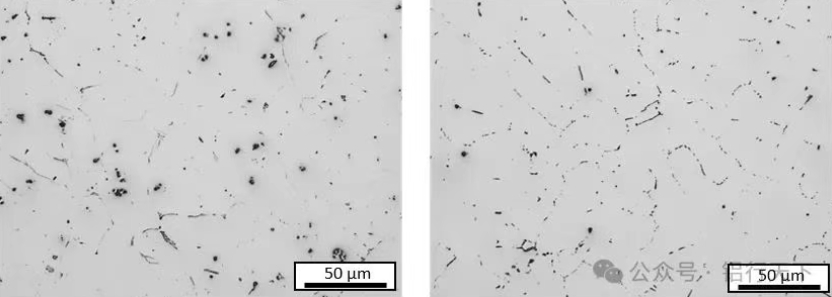

Iron (Fe) imakhudza kwambiri kulimba kwa fracture kuposa mphamvu. Mu 6XXX alloys, Fe phases amakonda kupanga β-phase (Al₅(FeMn)Si kapena Al₈.₉(FeMn)₂Si₂) panthawi yoponya. Magawo amenewa ndi aakulu, okhotakhota, ndipo amasokoneza extrusion (yomwe yafotokozedwa mkuyu 2a). Pa homogenization, zinthu zolemetsa (Fe, Mn, etc.) zimafalikira, ndipo magawo akuluakulu aang'ono amakhala ochepa komanso ozungulira (mkuyu 2b).

Kuchokera pazithunzi za kuwala kokha, n'zovuta kusiyanitsa magawo osiyanasiyana, ndipo n'zosatheka kuwerengera modalirika. Pa Innoval, timayesa ma billet homogenization pogwiritsa ntchito njira yathu yodziwira zinthu zamkati (FDC), yomwe imapereka mtengo wa %α pamabilu. Izi zimatithandiza kuwunika khalidwe la homogenization.

Chithunzi 2. Optical micrographs of billets (a) pamaso ndi (b) pambuyo homogenization.

Njira Yowunikira ndi Kuyika (FDC).

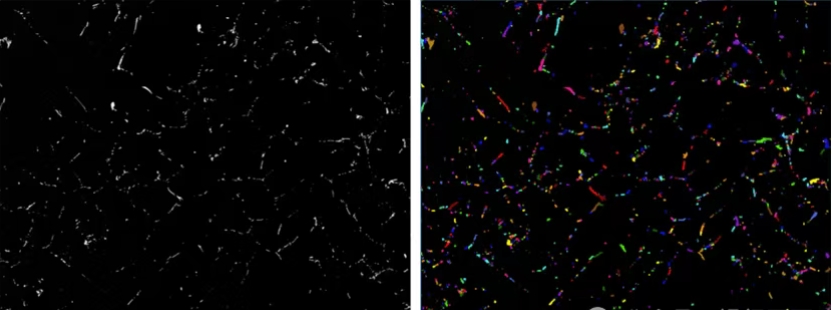

Chithunzi cha 3a chikuwonetsa chitsanzo chopukutidwa chomwe chimawunikidwa ndi makina owonera ma electron microscopy (SEM). Njira yotchingira imvi imagwiritsidwa ntchito polekanitsa ndi kuzindikira ma intermetallics, omwe amawoneka oyera mu Mkuyu 3b. Njirayi imalola kusanthula madera mpaka 1 mm², kutanthauza kuti zinthu zopitilira 1000 zitha kusanthula nthawi imodzi.

Chithunzi 3. (a) Chifaniziro cha ma elekitironi chakumbuyo cha homogenized 6060 billet, (b) chozindikiritsa mawonekedwe amunthu kuchokera ku (a).

Kupanga Tinthu

Innoval system ili ndi chowunikira cha Oxford Instruments Xplore 30 energy-dispersive X-ray (EDX). Izi zimalola kusonkhanitsa mwachangu kwazithunzi za EDX kuchokera kumalo aliwonse odziwika. Izi sipekitiramu, ndi tinthu zikuchokera angadziŵike, ndi wachibale Fe: Si chiŵerengero inferred.

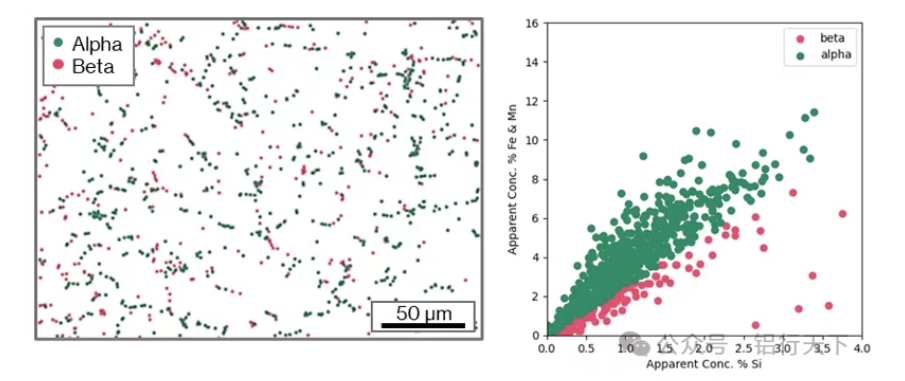

Kutengera ndi Mn kapena Cr zomwe zili mu alloy, zinthu zina zolemetsa zithanso kuphatikizidwa. Kwa ma aloyi 6XXX (nthawi zina okhala ndi Mn wofunikira), chiŵerengero cha (Fe + Mn):Si chimagwiritsidwa ntchito ngati chisonyezero. Izi zitha kufananizidwa ndi zomwe zimadziwika kuti Fe-containing intermetallics.

β-phase (Al₅(FeMn)Si kapena Al₈.₉(FeMn)₂Si₂): (Fe+Mn):Si chiŵerengero ≈ 2. α-phase (Al₁₂(FeMn)₃Si kapena Al₈.₃(FeMn)₂5 malingana ndi. Mapulogalamu athu achizolowezi amatilola kuti tiyike pakhomo ndikuyika gawo lililonse ngati α kapena β, kenaka jambulani malo awo mkati mwa microstructure (mkuyu 4). Izi zimapereka pafupifupi peresenti ya osinthidwa α mu homogenized billet.

Chithunzi 4. (a) Mapu owonetsa α- ndi β-classified particles, (b) chigawo chobalalitsa cha (Fe + Mn):Si chiŵerengero.

Zimene Data Ingatiuze

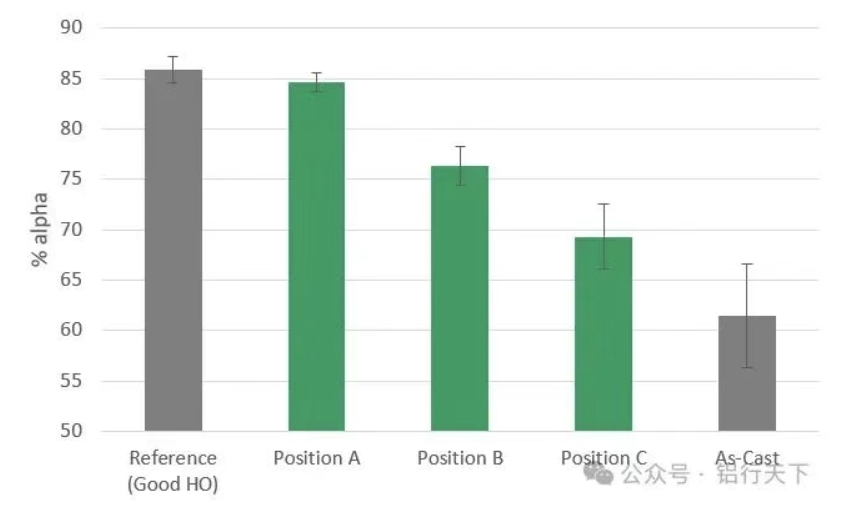

Chithunzi 5 chikuwonetsa chitsanzo cha momwe chidziwitsochi chimagwiritsidwira ntchito. Pachifukwa ichi, zotsatira zimasonyeza kutentha kosafanana mkati mwa ng'anjo inayake, kapena mwina kutentha kwa setpoint sikunafike. Kuti muwunikire bwino milandu yotereyi, ma billet oyeserera ndi mabulogu odziwika bwino amafunikira. Popanda izi, mulingo wa %α woyembekezeka wa kaphatikizidwe ka aloyi sungathe kukhazikitsidwa.

Chithunzi 5. Kuyerekeza % α m'magawo osiyanasiyana a ng'anjo yosagwira bwino ntchito ya homogenization.

Nthawi yotumiza: Aug-30-2025