Kafukufuku wochuluka wachitika pa kuwonjezera kwa zinthu zapadziko lapansi (REEs) ku 7xxx, 5xxx, ndi 2xxx mndandanda wa aluminiyamu aloyi, kusonyeza zotsatira zochititsa chidwi. Makamaka, 7xxx mndandanda wa aluminiyamu alloys, omwe ali ndi zinthu zingapo zopangira ma alloying, nthawi zambiri amakhala ndi tsankho lambiri pakusungunuka ndi kuponyera, zomwe zimapangitsa kuti pakhale magawo ambiri a eutectic. Izi zimachepetsa kulimba komanso kukana dzimbiri, kusokoneza magwiridwe antchito a alloy. Kuphatikizika kwa zinthu zosowa zapadziko lapansi mu zosakaniza za aluminiyamu zophatikizika kwambiri kumatha kuyeretsa mbewu, kupondereza tsankho, ndikuyeretsa matrix, potero kuwongolera kamangidwe kake ndi zinthu zonse.

Posachedwapa, mtundu wina woyenga tirigu wapamwamba kwambiri watchuka kwambiri. Oyenga awa amapezerapo mwayi pazinthu zapadziko lapansi monga La ndi Ce kuti apititse patsogolo kufowokeka kwa malire a tirigu ndi tirigu. Izi sizimangoyenga mbewu komanso zimalimbikitsa kubalalitsidwa kofanana kwa precipitates, kupondereza recrystallization, komanso kumapangitsanso bwino aloyi ductility, potsirizira pake kumawonjezera zokolola mu njira zowonjezera.

Mu 7xxx mndandanda wa aluminiyamu aloyi, zinthu zapadziko lapansi zosowa nthawi zambiri zimawonjezeredwa m'njira zitatu:

1.Zosowa zapadziko lapansi zokha;

2.Kuphatikizika kwa Zr ndi zinthu zosowa zapadziko lapansi;

3.Kuphatikizika kwa Zr, Cr, ndi zinthu zosowa zapadziko lapansi.

Zomwe zili muzinthu zapadziko lapansi zomwe zimasowa nthawi zambiri zimayendetsedwa mkati mwa 0.1-0.5 wt%.

Njira Zosowa Zapadziko Lapansi

Zinthu zosawerengeka zapadziko lapansi monga La, Ce, Sc, Er, Gd, ndi Y zimathandizira kupanga ma aluminiyamu pogwiritsa ntchito njira zingapo:

Kukonzanso kwa mbewu: Zinthu zapadziko lapansi zomwe sizipezeka kawirikawiri zimagawikana mofanana zomwe zimakhala ngati malo opangira ma nucleation, kutembenuza ma dendritic kukhala njere zofananira, zomwe zimapangitsa mphamvu ndi ductility.

Kuletsa tsankho: Pakusungunuka ndi kulimba, zinthu zapadziko lapansi zosawerengeka zimalimbikitsa kugawa zinthu zofanana, kuchepetsa mapangidwe a eutectic, ndikuwonjezera kachulukidwe ka matrix.

Kuyeretsedwa kwa matrix: Y, La, ndi Ce amatha kuchitapo kanthu ndi zonyansa zomwe zimasungunuka (O, H, N, S) kuti apange zinthu zokhazikika, kuchepetsa zomwe zili ndi gasi ndi inclusions, zomwe zimapangitsa kuti alloy apangidwe bwino.

Kusintha kwa mayendedwe a recrystallization: Zinthu zina zosowa zapadziko lapansi zimatha kuyika malire a tirigu ndi magawo ang'onoang'ono, kulepheretsa kusuntha komanso kusamuka kwa malire. Izi zimachedwetsa kukonzanso ndikusunga zomangira zabwino za subgrain panthawi yamafuta, ndikuwongolera mphamvu zonse komanso kukana dzimbiri.

Zinthu Zofunika Kwambiri Zapadziko Lapansi ndi Zotsatira Zake

Scandium (Sc)

Sc ili ndi utali wocheperako kwambiri wa atomiki pakati pa zinthu zomwe sizikupezeka padziko lapansi komanso ndichitsulo chosinthira. Ndiwothandiza kwambiri pakuwonjezera mphamvu za ma aluminiyamu opunduka.

Mu zotayidwa zotayidwa, Sc imayenda ngati Al₃Sc yogwirizana, kukulitsa kutentha kwa recrystallization ndikupondereza kuphulika kwambewu.

Zikaphatikizidwa ndi Zr, tinthu tating'ono tating'ono ta Al₃(Sc,Zr) tomwe timatentha kwambiri, timapanga tinthu tating'ono ting'onoting'ono tomwe timatulutsa timadzi tambiri tambiri tambiri tambiri tambiri tambiri tambiri tambiri tambiri tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'ono tating'onoting'ono. Izi zimawonjezera mphamvu, kukana kutopa, komanso kupsinjika-kuwonongeka kwa ntchito.

Kuchuluka kwa Sc kumatha kupangitsa tinthu tating'onoting'ono ta Al₃(Sc,Zr), kuchepetsa kuthekera kokonzanso, mphamvu, ndi ductility.

Erbium (Er)

Er imagwira ntchito mofanana ndi Sc koma ndiyotsika mtengo.

Mu 7xxx ma aloyi angapo, zowonjezera za Er zimayenga mbewu, zimalepheretsa kusuntha kwa malire ndi kusamuka kwa malire a tirigu, kupondereza kukonzanso, ndikuwonjezera mphamvu.

Mukaphatikizidwa ndi Zr, Al₃ (Er, Zr) tinthu tating'onoting'ono tating'ono tating'ono tating'ono tating'ono tating'onoting'ono tomwe timatentha kwambiri kuposa Al₃Er yekha, ndikupereka kuponderezedwa kwabwinoko.

Er yochulukira imatha kupanga magawo a Al₈Cu₄Er, kuchepetsa mphamvu zonse komanso ductility.

Gadolinium (Gd)

Zowonjezera za Gd zocheperako zimayeretsa njere, zimawonjezera mphamvu ndi ductility, ndikuwonjezera kusungunuka kwa Zn, Mg, ndi Cu mu matrix.

Zotsatira za Al₃(Gd,Zr) zikhomo zimasuntha ndi malire a subgrain, kupondereza recrystallization. Kanema wokangalika amapangikanso pamalo ambewu, zomwe zimalepheretsa kukula kwa mbewu.

Kuchulukitsitsa kwa Gd kungayambitse kugwa kwa tirigu ndi kuwonongeka kwa makina.

Lanthanum (La), Cerium (Ce), ndi Yttrium (Y)

La amayenga mbewu, amachepetsa mpweya wa okosijeni, ndipo amapanga filimu yogwira ntchito pamtunda kuti alepheretse kukula.

La ndi Ce amalimbikitsa GP zone ndi η′ gawo mpweya, kukulitsa mphamvu ya matrix ndi kukana dzimbiri.

Y imatsuka matrix, imalepheretsa kusungunuka kwa zinthu zazikuluzikulu za alloying mu njira yolimba, imalimbikitsa nucleation, ndipo imachepetsa kusiyana komwe kulipo pakati pa malire a tirigu ndi zamkati, kupititsa patsogolo kukana kwa dzimbiri.

Kuchulukirachulukira kwa La, Ce, kapena Y kumatha kupangitsa kuti pakhale ma coarse blocky compounds, omwe amachepetsa ductility ndi mphamvu.

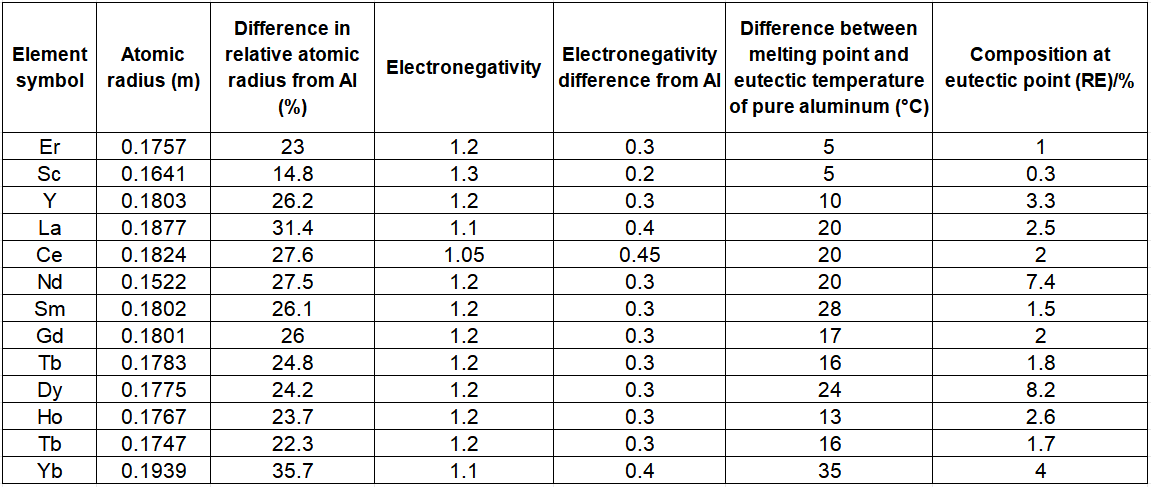

Katundu wa zinthu zazikulu zosowa padziko lapansi ndi mawonekedwe awo mu aluminiyamu

Nthawi yotumiza: Aug-21-2025