Kuyesa kwamphamvu kwamphamvu kumagwiritsidwa ntchito makamaka kuti adziwe kuthekera kwa zida zachitsulo kukana kuwonongeka panthawi yotambasula, ndipo ndi chimodzi mwazofunikira pakuwunika momwe zinthu zimagwirira ntchito.

1. Kuyesa kwamphamvu

Kuyesa kwamphamvu kumatengera mfundo zoyambira zamakanika azinthu. Pogwiritsa ntchito katundu wovuta kuzinthu zakuthupi pansi pazifukwa zina, zimayambitsa kusokonezeka kwapang'onopang'ono mpaka chitsanzo chisweke. Pa mayeso, mapindikidwe chitsanzo experimental pansi katundu osiyana ndi katundu pazipita pamene yopuma chitsanzo olembedwa, kuti kuwerengera zokolola mphamvu, kumakoka mphamvu ndi zizindikiro zina ntchito za zinthu.

Kupanikizika σ = F/A

σ ndi mphamvu yolimbikira (MPa)

F ndiye kuchuluka kwamphamvu (N)

A ndi gawo laling'ono lachitsanzo

2. Njira yokhotakhota

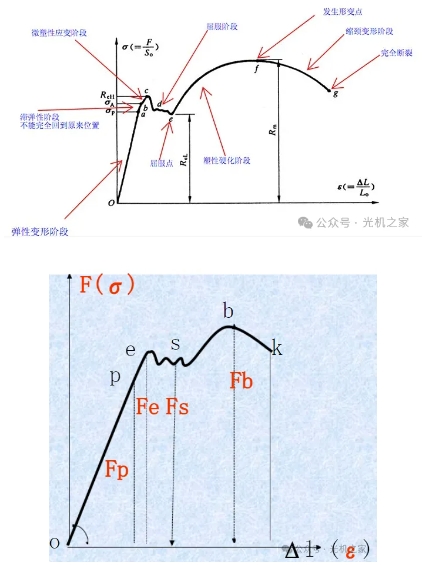

Kusanthula kwa magawo angapo a njira yotambasula:

a. Mu gawo la OP lomwe lili ndi katundu wocheperako, kutalika kwake kuli muubwenzi wofananira ndi katundu, ndipo Fp ndiye katundu wambiri kuti asunge mzere wowongoka.

b. Mtolo ukadutsa Fp, mayendedwe okhazikika amayamba kutenga ubale wopanda mzere. Chitsanzocho chimalowa mu gawo loyamba la deformation, ndipo katunduyo amachotsedwa, ndipo chitsanzocho chikhoza kubwerera ku chikhalidwe chake choyambirira ndi kupunduka.

c. Pambuyo pa katunduyo kuposa Fe, katunduyo amachotsedwa, gawo la deformation limabwezeretsedwa, ndipo gawo la zotsalira zotsalira zimasungidwa, zomwe zimatchedwa pulasitiki deformation. Fe imatchedwa malire otanuka.

d. Pamene katundu akuwonjezeka kwambiri, piritsi lolimba limasonyeza sawtooth. Pamene katundu sakuchulukirachulukira kapena kuchepa, chodabwitsa cha kufalikira kosalekeza kwa chitsanzo choyesera chimatchedwa kudzipereka. Pambuyo pobereka, chitsanzocho chimayamba kupangidwa ndi pulasitiki yowonekera.

e. Pambuyo popereka, chitsanzo chikuwonetsa kuwonjezeka kwa kukana kwa deformation, kuuma kwa ntchito ndi kulimbitsa ma deformation. Pamene katunduyo afika Fb, gawo lomwelo la chitsanzo limachepa kwambiri. Fb ndiye malire amphamvu.

f. Chochitika cha shrinkage chimayambitsa kuchepa kwa mphamvu yobereka ya chitsanzo. Pamene katunduyo afika Fk, chitsanzo chimasweka. Izi zimatchedwa katundu wosweka.

Zokolola Mphamvu

Zokolola mphamvu ndi pazipita kupsyinjika mtengo kuti zinthu zitsulo akhoza kupirira kuyambira chiyambi mapindikidwe pulasitiki kumaliza fracture pamene pansi mphamvu kunja. Mtengo uwu ndi womwe umakhala wofunikira pomwe zinthu zimasintha kuchokera pagawo la elastic deformation kupita pagawo la pulasitiki.

Gulu

Mphamvu zokolola zapamwamba: zimatanthawuza kupsinjika kwakukulu kwa chitsanzo mphamvu isanagwere kwa nthawi yoyamba pamene kulolera kumachitika.

Mphamvu zokolola zotsika: zimatanthawuza kupsinjika kochepa mu gawo la zokolola pamene zotsatira zoyamba zosakhalitsa zimanyalanyazidwa. Popeza mtengo wa zokolola zochepa zimakhala zokhazikika, nthawi zambiri zimagwiritsidwa ntchito ngati chizindikiro cha kukana kwa zinthu, zomwe zimatchedwa zokolola kapena mphamvu zokolola.

Fomula yowerengera

Kwa mphamvu zokolola zapamwamba: R = F / Sₒ, kumene F ndi mphamvu yaikulu mphamvu isanayambe kugwa kwa nthawi yoyamba mu gawo la zokolola, ndipo S- ndilo gawo loyambirira lachitsanzo.

Kwa mphamvu zochepa zokolola: R = F / Sₒ, kumene F ndi mphamvu yochepa F kunyalanyaza zotsatira zoyamba zosakhalitsa, ndipo S- ndilo gawo loyambirira lachitsanzo.

Chigawo

Chigawo cha mphamvu zokolola nthawi zambiri chimakhala MPa (megapascal) kapena N/mm² (Newton pa square millimeter).

Chitsanzo

Tengani chitsulo chochepa cha carbon mwachitsanzo, malire ake okolola nthawi zambiri amakhala 207MPa. Mukagonjetsedwa ndi mphamvu yakunja yoposa malire awa, chitsulo chochepa cha carbon chidzatulutsa kusinthika kosatha ndipo sichingabwezeretsedwe; pamene agonjetsedwa ndi mphamvu yakunja yocheperapo malire awa, chitsulo chochepa cha carbon chikhoza kubwerera ku chikhalidwe chake choyambirira.

Mphamvu zokolola ndi chimodzi mwa zizindikiro zofunika powunika makina azinthu zachitsulo. Imawonetsa kuthekera kwazinthu kukana mapindidwe apulasitiki akamakhudzidwa ndi mphamvu zakunja.

Kulimba kwamakokedwe

Kulimba kwamphamvu ndi kuthekera kwazinthu kukana kuwonongeka pansi pa katundu wovuta, womwe umawonetsedwa makamaka ngati kupsinjika kwakukulu komwe zinthuzo zimatha kupirira panthawi yamphamvu. Pamene kupsinjika kwamphamvu pazinthuzo kupitilira mphamvu yake yokhazikika, zinthuzo zimawonongeka kapena kusweka kwa pulasitiki.

Fomula yowerengera

Njira yowerengera mphamvu yamatensile (σt) ndi:

σt = F / A

Pomwe F ndiye mphamvu yayikulu kwambiri (Newton, N) yomwe chithunzicho chingathe kupirira chisanasweka, ndipo A ndiye gawo loyambira lachitsanzocho (square millimeter, mm²).

Chigawo

Chigawo champhamvu chokhazikika chimakhala MPa (megapascal) kapena N/mm² (Newton pa lalikulu millimeter). 1 MPa ikufanana ndi Newtons 1,000,000 pa square mita imodzi, yomwenso ndi yofanana ndi 1 N/mm².

Zinthu zosonkhezera

Mphamvu yamagetsi imakhudzidwa ndi zinthu zambiri, kuphatikizapo mankhwala, microstructure, njira yopangira kutentha, njira yopangira, etc. Zida zosiyana zimakhala ndi mphamvu zosiyana siyana, kotero muzogwiritsira ntchito, ndizofunikira kusankha zipangizo zoyenera pogwiritsa ntchito makina a zipangizo.

Kugwiritsa ntchito bwino

Kulimba kwamphamvu ndi gawo lofunikira kwambiri pazasayansi yaukadaulo ndi uinjiniya, ndipo nthawi zambiri amagwiritsidwa ntchito poyesa makina azinthu. Pankhani ya mapangidwe apangidwe, kusankha zinthu, kuunika kwa chitetezo, ndi zina zotero, mphamvu zowonongeka ndizofunikira zomwe ziyenera kuganiziridwa. Mwachitsanzo, mu zomangamanga, mphamvu yachitsulo yachitsulo ndi yofunika kwambiri kuti mudziwe ngati ikhoza kupirira katundu; m'munda wazamlengalenga, kulimba kwamphamvu kwa zinthu zopepuka komanso zamphamvu kwambiri ndiye chinsinsi chotsimikizira chitetezo cha ndege.

Kutopa kwamphamvu:

Kutopa kwachitsulo kumatanthawuza njira yomwe zipangizo ndi zigawo zake zimapangidwira pang'onopang'ono zowonongeka zowonongeka m'malo amodzi kapena angapo pansi pa kupsinjika kwa cyclic kapena cyclic kupsyinjika, ndipo ming'alu kapena fractures yadzidzidzi imachitika pakatha maulendo angapo.

Mawonekedwe

Mwadzidzidzi mu nthawi: Kutopa kwachitsulo nthawi zambiri kumachitika mwadzidzidzi m'kanthawi kochepa popanda zizindikiro zoonekeratu.

Malo omwe ali pamalo: Kulephera kutopa kumachitika m'madera omwe ali ndi nkhawa.

Kukhudzidwa kwa chilengedwe ndi zolakwika: Kutopa kwachitsulo kumakhudzidwa kwambiri ndi chilengedwe komanso zolakwika zazing'ono mkati mwazinthu, zomwe zimatha kufulumizitsa kutopa.

Zinthu zosonkhezera

Kupsyinjika matalikidwe: Kuchuluka kwa nkhawa kumakhudza mwachindunji moyo wotopa wachitsulo.

Avereji ya kupsinjika maganizo: Kuchuluka kwa kupanikizika kwapakati, kumachepetsa moyo wa kutopa kwachitsulo.

Kuchuluka kwa mizunguliro: Nthawi zambiri chitsulo chikakhala ndi vuto la cyclic kapena kupsyinjika, m'pamenenso kumawonjezera kuwonongeka kwa kutopa.

Njira zodzitetezera

Konzani kusankha zinthu: Sankhani zida zomwe zili ndi malire otopa kwambiri.

Kuchepetsa kupsinjika: Chepetsani kupsinjika maganizo kudzera m'mapangidwe apangidwe kapena njira zopangira, monga kugwiritsa ntchito kusintha kwa ngodya zozungulira, kukulitsa miyeso yodutsa, ndi zina.

Pamwamba mankhwala: kupukuta, kupopera mbewu mankhwalawa, etc. pa zitsulo pamwamba kuchepetsa zilema ndi kusintha kutopa mphamvu.

Kuyang'anira ndi kukonza: Yang'anani nthawi zonse zigawo zachitsulo kuti muwone msanga ndikukonza zolakwika monga ming'alu; sungani mbali zomwe zimakonda kutopa, monga kusintha ziwalo zowonongeka ndi kulimbikitsa maulalo ofooka.

Metal kutopa ndi wamba zitsulo kulephera akafuna, amene yodziwika ndi mwadzidzidzi, dera ndi tilinazo chilengedwe. Kupsyinjika matalikidwe, avareji kupsyinjika kukula ndi kuchuluka kwa mkombero ndi zinthu zazikulu zomwe zimakhudza zitsulo kutopa.

SN curve: imalongosola moyo wa kutopa kwa zinthu zomwe zili pansi pa zovuta zosiyanasiyana, pomwe S imayimira kupsinjika ndipo N imayimira kuchuluka kwazovuta.

Kutopa kwa coefficient formula:

(Kf = Ka \cdot Kb \cdot Kc \cdot Kd \cdot Ke)

Kumene (Ka) ndi katundu wa katundu, (Kb) ndi kukula kwake, (Kc) ndi kutentha, (Kd) ndi chinthu chapamwamba, ndipo (Ke) ndiye chinthu chodalirika.

Mafotokozedwe a masamu a SN curve:

(\ sigma^m N = C)

Kumene (\ sigma) kuli kupsinjika, N ndi chiwerengero cha kupsinjika maganizo, ndipo m ndi C ndizokhazikika.

Masitepe owerengera

Dziwani zosasintha:

Dziwani zofunikira za m ndi C kudzera muzoyesera kapena potengera zolemba zoyenera.

Dziwani za kupsinjika maganizo: Ganizirani za mawonekedwe enieni ndi kukula kwa gawolo, komanso kupsinjika maganizo komwe kumayambitsidwa ndi ma fillets, keyways, etc., kuti mudziwe kupsinjika maganizo K. Kuwerengera mphamvu ya kutopa: Malingana ndi SN curve ndi stress concentration factor, kuphatikizapo moyo wa mapangidwe ndi kupanikizika kwa ntchito ya gawolo, kuwerengera mphamvu ya kutopa.

2. Pulasitiki:

Plasticity imatanthawuza katundu wa chinthu chomwe, chikagwidwa ndi mphamvu yakunja, chimapanga mapindikidwe osatha popanda kusweka pamene mphamvu yakunja idutsa malire ake otanuka. Kupindika kumeneku sikungasinthe, ndipo zinthuzo sizingabwerere ku mawonekedwe ake oyambirira ngakhale mphamvu yakunja itachotsedwa.

Plasticity index ndi mawerengedwe ake

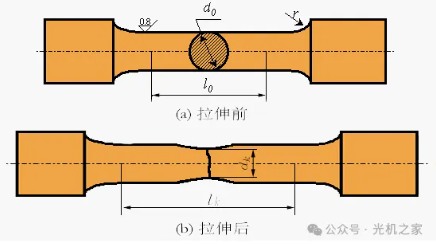

Elongation (δ)

Tanthauzo: Kutalikitsa ndi kuchuluka kwa kusinthika kwathunthu kwa gawo la gejiyo pambuyo poti chithunzicho chitaphwanyidwa mpaka kutalika kwa geji yoyambirira.

Fomula: δ = (L1 – L0) / L0 × 100%

Kumene L0 ndi kutalika kwa geji yoyambirira ya chitsanzo;

L1 ndiye kutalika kwa gauge pambuyo poti wasweka.

Kuchepetsa gawo (Ψ)

Tanthauzo: Kuchepetsa kwamagulu ndi chiwerengero cha kuchepetsa kwakukulu kwa malo ozungulira pamphepete mwa khosi pambuyo poti chitsanzocho chathyoledwa kumalo oyambirira.

Fomula: Ψ = (F0 – F1) / F0 × 100%

Kumene F0 ndi gawo loyambirira lachitsanzo;

F1 ndi gawo lopatsirana pakhosi pomwe chithunzicho chasweka.

3. Kuuma

Kuuma kwachitsulo ndi ndondomeko ya katundu wamakina kuti muyese kuuma kwa zinthu zachitsulo. Zimasonyeza kukhoza kukana mapindikidwe mu voliyumu yapafupi pamtunda wazitsulo.

Gulu ndi chiwonetsero cha kuuma kwachitsulo

Kuuma kwachitsulo kumakhala ndi mitundu yosiyanasiyana komanso njira zoyimira motengera njira zosiyanasiyana zoyesera. Muphatikizepo izi:

Kuuma kwa Brinell (HB):

Kuchuluka kwa ntchito: Zomwe zimagwiritsidwa ntchito nthawi zambiri zikakhala zofewa, monga zitsulo zosakhala ndi chitsulo, chitsulo chisanatenthedwe kapena chikatsekeredwa.

Mfundo yoyesera: Ndi kukula kwina kwa mayeso, mpira wolimba wachitsulo kapena mpira wa carbide wa m'mimba mwake umakanikizidwa pamwamba pa chitsulo kuti uyesedwe, ndipo katunduyo amatsitsidwa pambuyo pa nthawi yodziwika, ndipo m'mimba mwake wa indentation pamtunda kuti ayesedwe.

Kuwerengera: Mtengo wa Brinell hardness ndi quotient yomwe imapezeka pogawa katundu ndi malo ozungulira a indentation.

Kuuma kwa Rockwell (HR):

Kuchuluka kwa ntchito: Nthawi zambiri amagwiritsidwa ntchito pazinthu zolimba kwambiri, monga kuuma pambuyo pochiritsa kutentha.

Mfundo yoyesera: Yofanana ndi kuuma kwa Brinell, koma kugwiritsa ntchito ma probe osiyanasiyana (diamondi) ndi njira zosiyanasiyana zowerengera.

Mitundu: Kutengera kugwiritsa ntchito, pali HRC (zazinthu zolimba kwambiri), HRA, HRB ndi mitundu ina.

Kuuma kwa Vickers (HV):

Kuchuluka kwa ntchito: Yoyenera kusanthula maikulosikopu.

Mfundo yoyesera: Kanikizani zinthu zomwe zili ndi katundu wosakwana 120kg ndi diamondi lalikulu cone indenter yokhala ndi ngodya ya vertex ya 136 °, ndikugawaniza malo a dzenje lazinthu ndi mtengo wolemetsa kuti mupeze kuuma kwa Vickers.

Kuuma kwa Leeb (HL):

Mawonekedwe: Choyesa kuuma chonyamula, chosavuta kuyeza.

Mfundo yoyesera: Gwiritsani ntchito kudumpha komwe kumapangidwa ndi mutu wa mpirawo mutakhudza kuuma kwa pamwamba, ndikuwerengera kuuma kwake ndi chiŵerengero cha liwiro la nkhonya pa 1mm kuchokera pachitsanzo kupita ku liwiro lamphamvu.

Nthawi yotumiza: Sep-25-2024