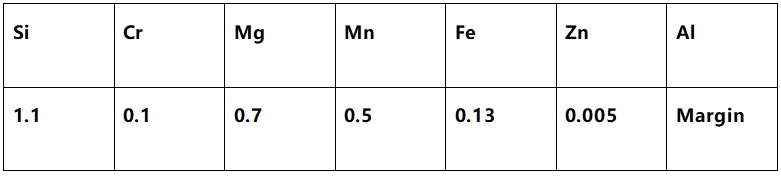

1. Kapangidwe ka aloyi

2. Homogenization Njira

390 ℃ x kutchinjiriza kwa 1.0h + 575 ℃ x kutchinjiriza kwa 8h, kuzirala kwamphepo yamphamvu mpaka 200 ℃ kenako kuzirala kwa madzi.

3. Mapangidwe a Metallographic

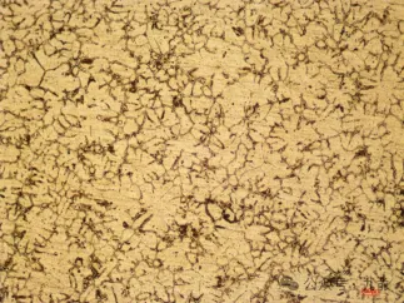

Chithunzi 1 Kapangidwe kazitsulo kapakati pa 6082 alloy ingot, yokhazikitsidwa ndi Keller reagent, yokhala ndi ma dendrites opangidwa bwino.

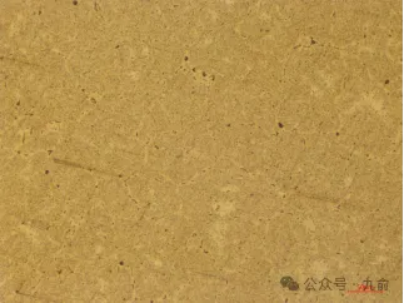

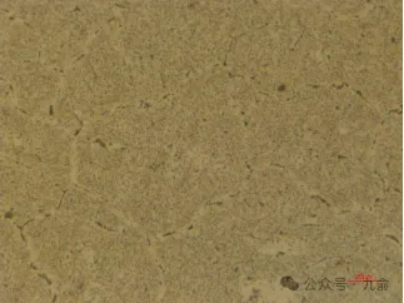

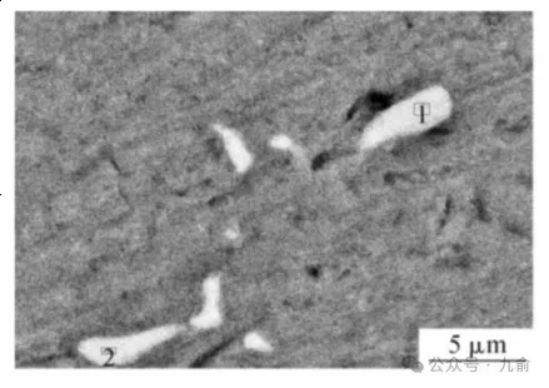

Chithunzi 2 Mapangidwe a Metallographic pachimake cha 6082 alloy ingot, okhazikika ndi Keller reagent, ndi kapangidwe pambuyo pa yankho lolimba.

4. Mmene homogenization kutentha mankhwala pa aloyi dongosolo

4.1 Monga momwe tawonetsera pa Chithunzi 1, alloy ali ndi ma dendrites opangidwa bwino mu chigawo choponyedwa, ndipo pali chiwerengero chachikulu cha magawo osagwirizana ndi mpweya wa mpweya pamalire a tirigu.

4.2 Popeza kusungunuka kwa zinthu zosiyanasiyana kumakhala kosiyana pamene aloyiyo imalimba, chodabwitsa ichi chokhazikika chokhazikika chimatsogolera kumagulu osagwirizana a solute mkati mwa kristalo, omwe amawonetseredwa makamaka mumbadwo wa magawo ambiri a mpweya wa intaneti pa malire a tirigu.

4.3 Mu microstructure pambuyo pa chithandizo cha homogenization (Chithunzi 2), kuchuluka kwa magawo omwe amawombera pamalire a tirigu kumachepetsedwa kwambiri, ndipo kukula kwambewu kumawonjezeka mofanana. Izi ndichifukwa choti kufalikira kwa ma atomu kumakulitsidwa pansi pa kutentha kwakukulu, kuthetsa tsankho ndi kusungunuka kwa gawo losagwirizana kumachitika mu ingot, ndipo ma netiweki pamalire ambewu amasungunuka pang'ono.

4.4 Kupyolera mu kusanthula kwa SEM, monga momwe tawonetsera mu FIG3, magawo osiyanasiyana a gawo lokhazikika adasankhidwa kuti afufuze EDS, kutsimikizira kuti gawo lachiwopsezo linali gawo la Al (MnFe)Si.

4.5 Pakuponyera alloy, kuchuluka kwa mpweya wokhala ndi Mn kumapangidwa, ndipo gawo lina limasungidwa mu njira yolimba ya supersaturated. Pambuyo pa kutentha kwambiri komanso chithandizo cha nthawi yaitali cha homogenization, Mn supersaturated mu masanjidwewo amadziwikiratu mu mawonekedwe a mankhwala okhala ndi Mn, omwe amawonetsedwa ngati kuchuluka kwa tinthu tambiri tambiri tambiri tambiri timene timawonongeka mu kristalo (Chithunzi 2).

4.6 Popeza gawo lomwe lakwera lili ndi gawo la Mn, limakhala ndi kukhazikika kwamafuta. Ndi kulimbikira kwa ma atomiki kufalikira, ndi Al(MnFe)Si gawo particles pang'onopang'ono kusonyeza makhalidwe spheroidization.

Fig.3 Al(MnFe)Si gawo mu 6082 aloyi

5. Mmene njira yothetsera ukalamba dongosolo pa makina katundu

Pambuyo homogenization, maukonde mpweya gawo poyamba pa malire ambewu 6082 aloyi ndi kusungunuka, amene angathe kusintha mabuku mawotchi zimatha chitsanzo. Pa nthawi yomweyo, khola kutentha zosagwira gawo Al(MnFe)Si gawo ndi zina spheroidized, amene akhoza bwino pini dislocations. Izi zikusonyeza kuti mabuku ntchito zinthu adzakhala bwino pambuyo homogenization kutentha mankhwala.

6. Mapeto

6.1 Ingot ya 6082 aluminium alloy ingot ili ndi ma dendrites opangidwa bwino komanso kuchuluka kwa magawo a mpweya osafanana ndi maukonde pamalire ambewu.

6.2 Pambuyo pa chithandizo cha homogenization, kuyang'ana kwa microscopic kunawonetsa kuti kuchuluka kwa magawo omwe adagwa kunachepetsedwa kwambiri, ndipo kukula kwambewu kunakula mofanana. Kuthetsa tsankho ndi kusungunuka kwa gawo lopanda mgwirizano kunachitika mu ingot, ndipo zopangira maukonde pamalire a tirigu zinasungunuka pang'ono.

6.3 Poponya 6082 aloyi, gawo la mpweya wa Al(MnFe)Si limapangidwa. Gawo lamvulali lili ndi gawo la Mn ndipo lili ndi kukhazikika kwamafuta. Pamene ndondomeko homogenization chikuchitika, mpweya gawo particles pang'onopang'ono kusonyeza spheroidization makhalidwe. Tinthu tating'onoting'ono ta Mn timamwazikana mofanana ndikulowa mu kristalo.

6.4 Pambuyo pa chithandizo cha homogenization, kusungunuka kwa maukonde kunayambika gawo limasonyeza kuti ntchito yonse ya ingot imakula bwino pambuyo pa chithandizo cha kutentha kwa homogenization.

Nthawi yotumiza: Jun-08-2025