Aluminiyamu 6063 ndi aloyi otsika aloyi Al-Mg-Si mndandanda kutentha-treatable aluminiyamu aloyi. Ili ndi magwiridwe antchito abwino kwambiri opangira ma extrusion, kukana kwa dzimbiri komanso makina ambiri. Amagwiritsidwanso ntchito kwambiri m'makampani amagalimoto chifukwa cha utoto wake wosavuta wa okosijeni. Ndi kukwera kwa kachitidwe ka magalimoto opepuka, kugwiritsa ntchito 6063 aluminium alloy extrusion zida mumsika wamagalimoto kwachulukiranso.

The microstructure ndi katundu wa zipangizo extruded amakhudzidwa ndi zotsatira ophatikizana wa extrusion liwiro, extrusion kutentha ndi chiŵerengero extrusion. Pakati pawo, chiŵerengero cha extrusion chimatsimikiziridwa makamaka ndi kuthamanga kwa extrusion, kupanga bwino ndi zida zopangira. Pamene chiŵerengero cha extrusion chili chaching'ono, mapindikidwe a aloyi ndi ochepa ndipo kukonzanso kwa microstructure sikukuwonekera; kuonjezera chiŵerengero cha extrusion kumatha kuyeretsa kwambiri mbewu, kuphwanya gawo lachiwiri, kupeza microstructure yunifolomu, ndikusintha makina a alloy.

6061 ndi 6063 zotayidwa zotayidwa kukumana mphamvu recrystallization pa ndondomeko extrusion. Pamene kutentha kwa extrusion kumakhala kosalekeza, pamene chiŵerengero cha extrusion chikuwonjezeka, kukula kwa tirigu kumachepa, gawo lolimbikitsa limakhala lomwazika bwino, ndipo mphamvu yamakokedwe ndi elongation ya alloy ikuwonjezeka moyenerera; komabe, pamene chiŵerengero cha extrusion chikuwonjezeka, mphamvu yowonjezera yowonjezera yomwe ikufunika kuti iwonongeke imawonjezereka, zomwe zimapangitsa kuti kutentha kwapakati kuwonongeke, kuchititsa kuti kutentha kwa mkati kwa alloy kukwezeke, ndi kuchepa kwa ntchito. Kuyesera uku kumaphunzira momwe chiŵerengero cha extrusion, makamaka chiŵerengero chachikulu cha extrusion, pa microstructure ndi makina a 6063 aluminium alloy.

1 Zida zoyesera ndi njira

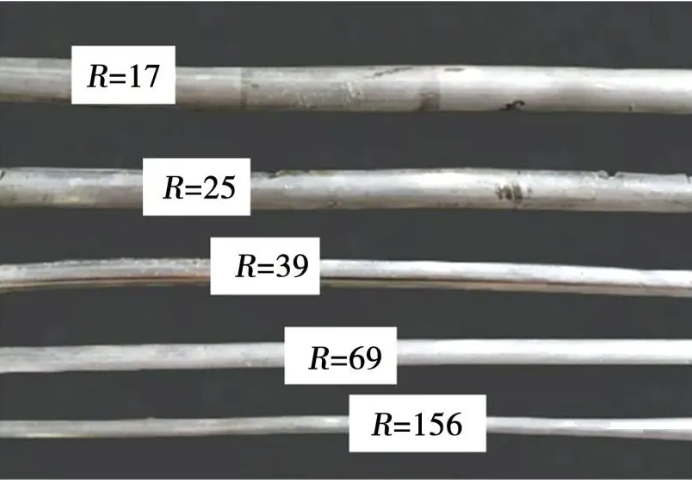

Zinthu zoyesera ndi 6063 aluminium alloy, ndipo mawonekedwe a mankhwala akuwonetsedwa mu Table 1. Kukula koyambirira kwa ingot ndi Φ55 mm × 165 mm, ndipo amasinthidwa kukhala billet extrusion ndi kukula kwa Φ50 mm × 150 mm pambuyo pa chithandizo cha homogenization pa 560 ℃ kwa 6 h. Billet imatenthedwa mpaka 470 ℃ ndikutentha. Kutentha kwa preheating kwa mbiya ya extrusion ndi 420 ℃, ndipo kutentha kwa nkhungu ndi 450 ℃. Pamene liwiro extrusion (extrusion ndodo kusuntha liwiro) V = 5 mm/s amakhalabe osasintha, 5 magulu osiyanasiyana mayeso chiŵerengero cha extrusion ikuchitika, ndi extrusion chiŵerengero R ndi 17 (logwirizana ndi kufa dzenje awiri D = 12 mm), 25 (D = 10 mm), 39 (D = 8 mm), 69 (D = 6 mm), 69 (D = 6 mm).

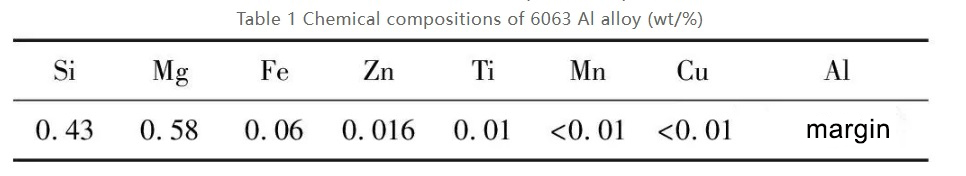

Table 1 Zolemba za Chemical za 6063 Al alloy (wt/%)

Pambuyo pa sandpaper akupera ndi makina kupukuta, zitsanzo metallographic anazikika ndi HF reagent ndi voliyumu gawo la 40% kwa pafupifupi 25 s, ndi kapangidwe metallographic wa zitsanzo ankaona pa LEICA-5000 kuwala microscope. Chitsanzo chowunikira mawonekedwe a 10 mm × 10 mm chinadulidwa kuchokera pakati pa gawo lotalikirapo la ndodo yotulutsidwa, ndipo kugaya ndi kuyika makina kunkachitidwa kuti achotse kupsinjika kwapamwamba. Ziwerengero zosakwanira za mapale a ndege zitatu za crystal {111}, {200}, ndi {220} za zitsanzozo zinayesedwa ndi X'Pert Pro MRD X-ray diffraction analyzer ya PANalytical Company, ndipo deta yapangidwe inakonzedwa ndi kufufuzidwa ndi pulogalamu ya X'Pert Data View ndi X'Pert Texture.

Chifaniziro chokhazikika cha alloy cast chinatengedwa kuchokera pakati pa ingot, ndipo chojambula chokhazikika chinadulidwa motsatira njira ya extrusion pambuyo pa extrusion. Kukula kwa dera la gauge kunali Φ4 mm×28 mm. Kuyesa kwamphamvu kunachitika pogwiritsa ntchito makina oyesa zinthu zapadziko lonse a SANS CMT5105 okhala ndi liwiro la 2 mm/min. Mtengo wapakati wa zitsanzo zitatu zokhazikika zinawerengedwa ngati deta ya katundu wamakina. Mapangidwe a fracture a zitsanzo zolimba adawonedwa pogwiritsa ntchito maikulosikopu ya electron (Quanta 2000, FEI, USA).

2 Zotsatira ndi zokambirana

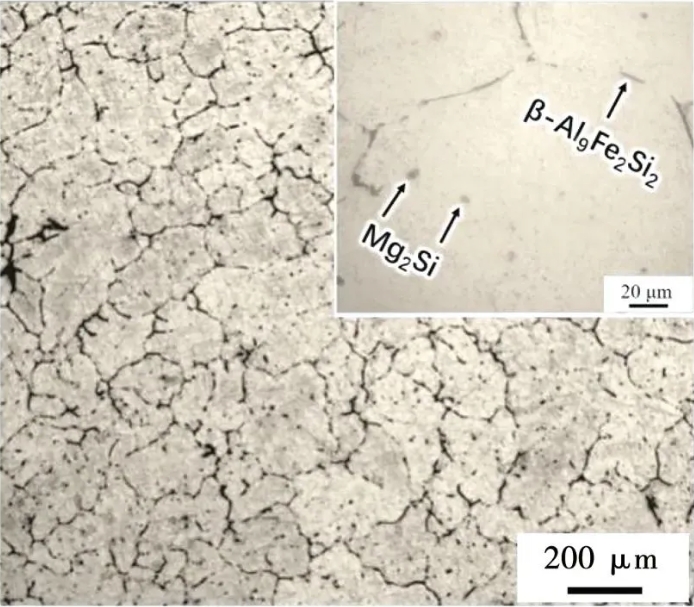

Chithunzi 1 chikuwonetsa metallographic microstructure ya as-cast 6063 aluminium alloy isanayambe komanso itatha chithandizo cha homogenization. Monga momwe tawonetsera pa Chithunzi 1a, mbewu za α-Al mu as-cast microstructure zimasiyana mu kukula, chiwerengero chachikulu cha reticular β-Al9Fe2Si2 magawo amasonkhana pa malire a tirigu, ndipo chiwerengero chachikulu cha granular Mg2Si magawo alipo mkati mwa mbewu. Ingot itatha kusinthidwa pa 560 ℃ kwa 6 h, gawo losagwirizana la eutectic pakati pa alloy dendrites linasungunuka pang'onopang'ono, zinthu za alloy zimasungunuka mu matrix, microstructure inali yunifolomu, ndipo kukula kwa tirigu kunali pafupifupi 125 μm (Chithunzi 1b).

Pamaso homogenization

Pambuyo uniformizing mankhwala pa 600 ° C kwa 6 hours

Chithunzi cha 1 Metallographic ya 6063 aluminium alloy isanayambe komanso itatha chithandizo cha homogenization

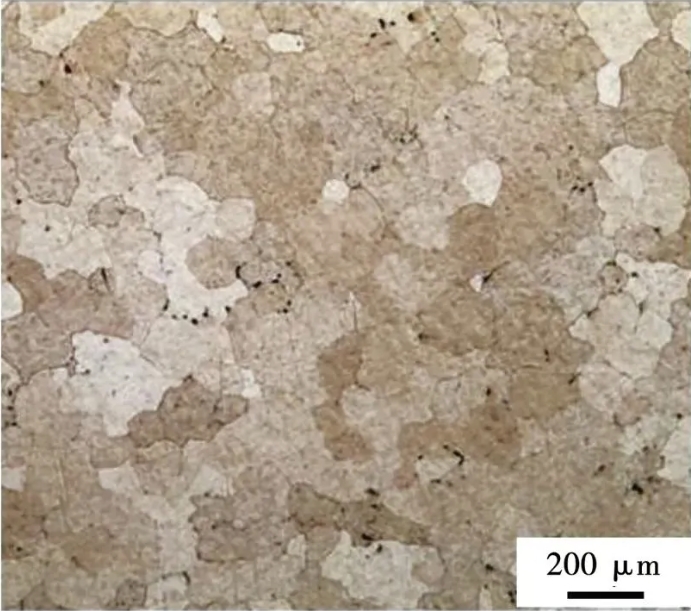

Chithunzi 2 chikuwonetsa mawonekedwe a 6063 aluminiyamu aloyi mipiringidzo yokhala ndi ma ratios osiyanasiyana. Monga momwe chithunzi 2, pamwamba khalidwe la 6063 zotayidwa aloyi mipiringidzo extruded ndi osiyana extrusion ratios ndi zabwino, makamaka pamene chiŵerengero extrusion chiwonjezeke kwa 156 (logwirizana ndi mipiringidzo extrusion kubwereketsa liwiro la 48 m/mphindi), kulibe zilema extrusion monga ming'alu ndi peeling, pamwamba pa 60 zitsulo zolumikizika ali ndi 60 zitsulo zotayidwa bwino pamwamba pa zitsulo zotayidwa. otentha extrusion kupanga ntchito pansi pa liwiro lalikulu ndi chiŵerengero chachikulu extrusion.

Chithunzi cha 2 Maonekedwe a ndodo za aluminiyamu 6063 zokhala ndi ma ratios osiyanasiyana

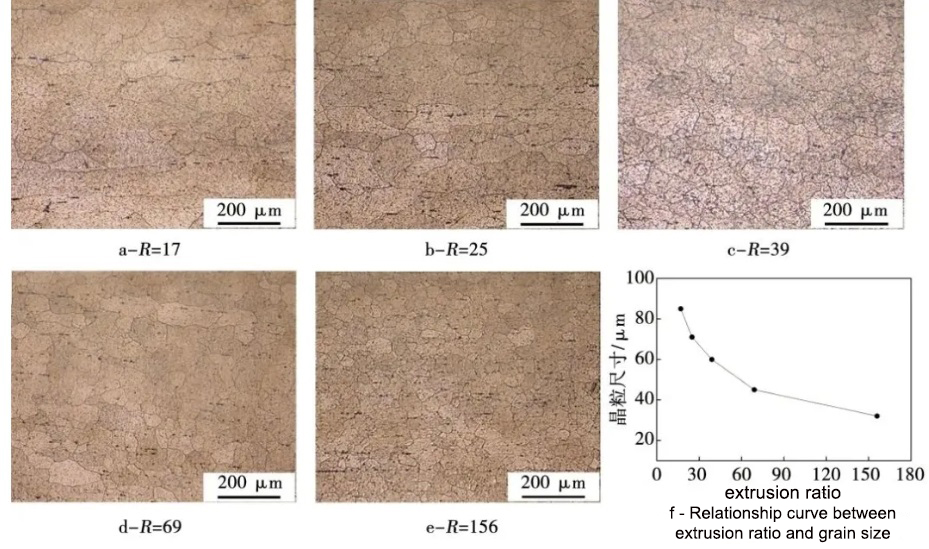

Chithunzi 3 chikuwonetsa mawonekedwe a metallographic a gawo longitudinal la 6063 aluminium alloy bar yokhala ndi ma ratios osiyanasiyana. Mapangidwe a njere a bar omwe ali ndi magawo osiyanasiyana a extrusion amawonetsa magawo osiyanasiyana akutalikira kapena kuwongolera. Pamene chiŵerengero cha extrusion ndi 17, njere zoyambirira zimatambasulidwa motsatira njira yowonjezera, limodzi ndi mapangidwe ang'onoang'ono a njere zowonjezeredwa, koma mbewuzo zimakhala zolimba, ndi kukula kwa tirigu pafupifupi 85 μm (Chithunzi 3a); pamene chiŵerengero cha extrusion ndi 25, mbewu zimakoka pang'onopang'ono, chiwerengero cha mbewu zowonjezeredwa chimawonjezeka, ndipo kukula kwa tirigu kumachepa kufika pafupifupi 71 μm (Chithunzi 3b); pamene chiŵerengero cha extrusion ndi 39, kupatulapo chiwerengero chochepa cha njere zopunduka, microstructure imapangidwa ndi njere za equiaxed recrystallized za kukula kwake, ndi kukula kwa tirigu pafupifupi 60 μm (Chithunzi 3c); pamene chiŵerengero cha extrusion ndi 69, ndondomeko yowonjezereka ya recrystallization imatsirizidwa, mbewu zoyamba zowonongeka zasinthidwa kukhala tirigu wopangidwa mofanana, ndipo kukula kwake kwambewu kumayengedwa pafupifupi 41 μm (Chithunzi 3d); pamene chiŵerengero cha extrusion ndi 156, ndi kupita patsogolo kwathunthu kwa ndondomeko yowonjezereka ya recrystallization, microstructure imakhala yofanana kwambiri, ndipo kukula kwambewu kumayeretsedwa kwambiri pafupifupi 32 μm (Chithunzi 3e). Ndi kuwonjezeka kwa chiŵerengero cha extrusion, ndondomeko yowonjezereka ya recrystallization imayenda bwino kwambiri, alloy microstructure imakhala yofanana, ndipo kukula kwambewu kumakonzedwa bwino (Chithunzi 3f).

Chithunzi cha 3 Mapangidwe a Metallographic ndi kukula kwa mbewu za gawo longitudinal la 6063 aluminiyamu aloyi ndodo zokhala ndi ma ratios osiyanasiyana.

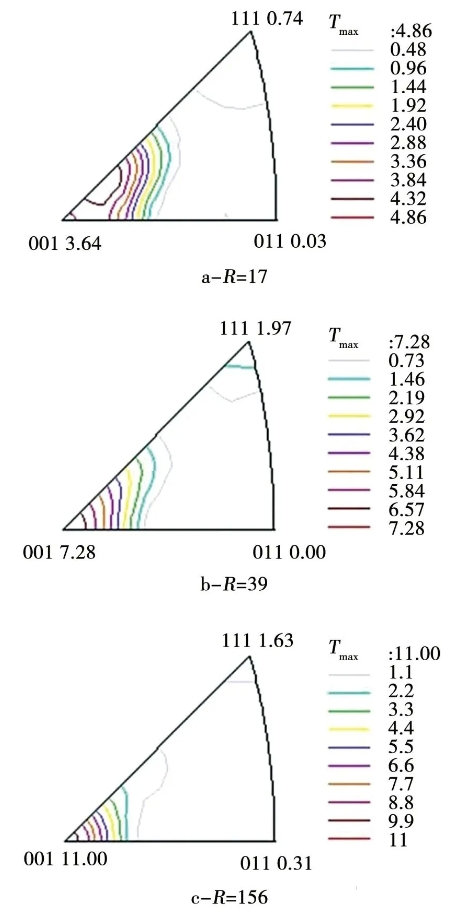

Chithunzi 4 chikuwonetsa ziwerengero zopingasa za 6063 aluminiyamu aloyi mipiringidzo yokhala ndi ma retiroti osiyanasiyana otuluka motsatira njira yotulutsira. Zitha kuwoneka kuti ma microstructures a mipiringidzo ya alloy yokhala ndi ma ratios osiyanasiyana a extrusion onse amatulutsa mawonekedwe odziwika bwino. Pamene chiwerengero cha extrusion ndi 17, chofooka <115>+<100> chimapangidwa (Chithunzi 4a); pamene chiŵerengero cha extrusion ndi 39, zigawo zapangidwe zimakhala zolimba kwambiri <100> kapangidwe kake ndi zochepa zofooka <115> kapangidwe kake (Chithunzi 4b); pamene chiŵerengero cha extrusion ndi 156, zigawo zowonongeka ndi <100> mawonekedwe ndi mphamvu zowonjezera kwambiri, pamene <115> mawonekedwe amatha (Chithunzi 4c). Kafukufuku wasonyeza kuti nkhope-centered kiyubiki zitsulo makamaka kupanga <111> ndi <100> waya mawonekedwe pa extrusion ndi kujambula. Kapangidwe kake kapangidwe, kutentha kwa chipinda cha chipinda cha aloyi kumawonetsa anisotropy yoonekeratu. Mphamvu yamapangidwe imawonjezeka ndi kuwonjezeka kwa chiŵerengero cha extrusion, kusonyeza kuti chiwerengero cha mbewu mumtundu wina wa kristalo wofanana ndi njira ya extrusion mu alloy pang'onopang'ono chikuwonjezeka, ndipo mphamvu yotalika yotalika ya aloyi ikuwonjezeka. Kulimbitsa njira za 6063 aluminiyamu aloyi otentha extrusion zipangizo monga zabwino kulimbikitsa mbewu, dislocation kulimbikitsa, kapangidwe kulimbitsa, etc. M'kati mwa osiyanasiyana ndondomeko magawo ntchito mu kafukufuku kuyesera, kuwonjezera extrusion chiŵerengero ali ndi kulimbikitsa pa pamwamba kulimbikitsa njira.

Chithunzi cha 4 Reverse pole cha 6063 aluminiyamu aloyi ndodo zokhala ndi ma retioti osiyanasiyana otuluka motsatira njira yotulutsira.

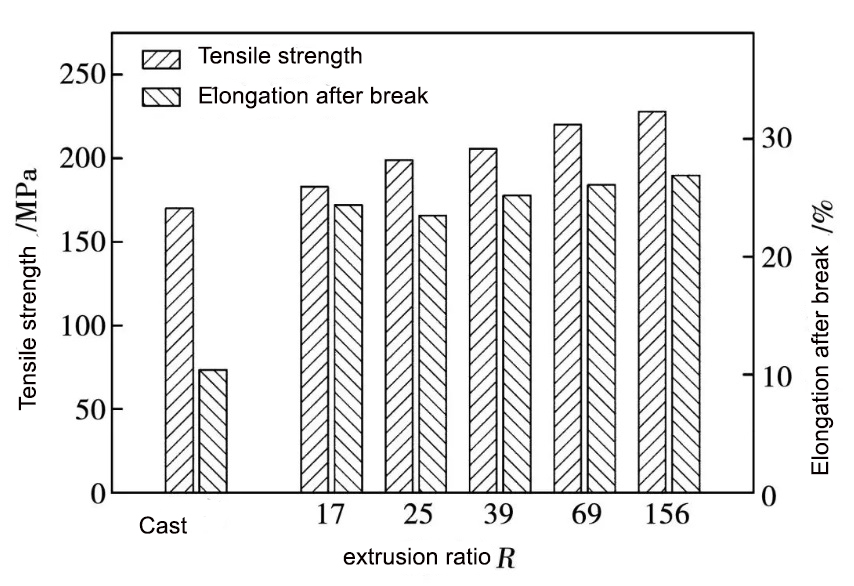

Chithunzi 5 ndi histogram wa katundu wamakokedwe wa 6063 zotayidwa aloyi pambuyo mapindikidwe pa osiyana chiŵerengero extrusion. Mphamvu yamphamvu ya alloy cast ndi 170 MPa ndipo elongation ndi 10.4%. Mphamvu yamakokedwe ndi elongation ya aloyi pambuyo extrusion bwino kwambiri, ndi kumakoka mphamvu ndi elongation pang'onopang'ono kuwonjezeka ndi kuwonjezeka chiŵerengero extrusion. Pamene chiŵerengero cha extrusion ndi 156, mphamvu yamakokedwe ndi elongation ya aloyi imafika pamtengo wapatali, womwe ndi 228 MPa ndi 26,9%, motero, womwe uli pafupi 34% kuposa mphamvu yamakomedwe ya aloyi ndi pafupifupi 158% kuposa elongation. Mphamvu yamakokedwe ya 6063 zotayidwa aloyi akalandira ndi lalikulu extrusion chiŵerengero ndi pafupi amakokedwe mphamvu mtengo (240 MPa) akamagwira 4-chiphaso ofanana njira angular extrusion (ECAP), amene ndi apamwamba kwambiri kuposa kumakokedwa mphamvu mtengo (171.1 MPa) akamagwira 1-pass ECAP extrusion wa 6063 zotayidwa aloyi. Zitha kuwoneka kuti chiŵerengero chachikulu cha extrusion chikhoza kusintha makina a alloy pamlingo wina.

Kupititsa patsogolo mphamvu zamakina a aloyi ndi chiŵerengero cha extrusion makamaka kumachokera ku kulimbikitsa kwambewu. Pamene chiŵerengero cha extrusion chikuwonjezeka, mbewu zimayengedwa ndipo kachulukidwe kameneka kamawonjezeka. Malire ochulukirapo a tirigu pagawo la unit akhoza kulepheretsa bwino kusuntha kwa dislocation, kuphatikizapo kusuntha pamodzi ndi kutsekeka kwa dislocations, potero kupititsa patsogolo mphamvu ya alloy. Mbeu zabwino kwambiri, zimakhala zovuta kwambiri malire a tirigu, ndi mapindikidwe apulasitiki amatha kumwazikana mumbewu zambiri, zomwe sizingathandize kupanga ming'alu, osasiya kufalitsa ming'alu. Mphamvu zambiri zimatha kutengeka panthawi yakuphwanyidwa, potero kuwongolera pulasitiki ya alloy.

Fig.5 Tensile katundu wa 6063 zotayidwa aloyi pambuyo kuponyera ndi extrusion

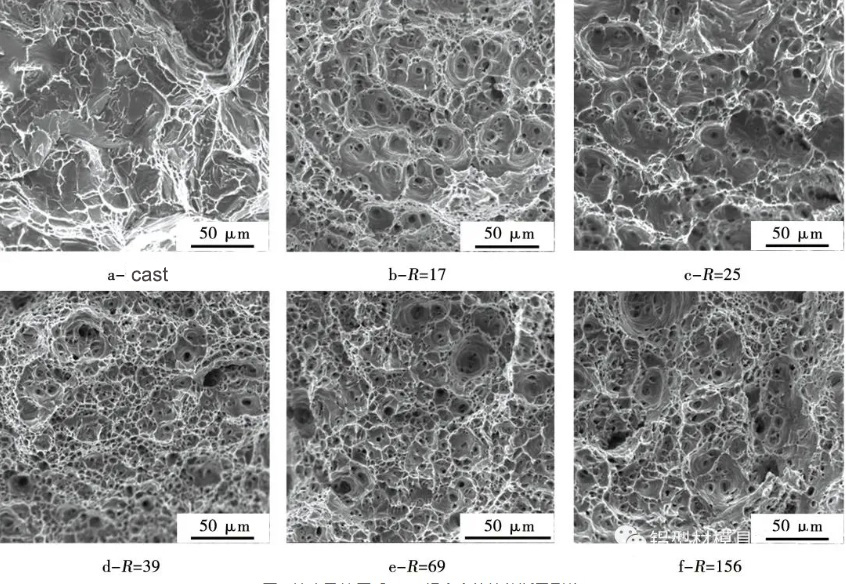

Kuwonongeka kwa morphology ya aloyi pambuyo pa kusinthika kosiyana ndi zosiyana zowonjezera kukuwonetsedwa mu Chithunzi 6. Palibe ma dimples omwe anapezeka mu fracture morphology of the as-cast sample (Figure 6a), ndipo fracture inkapangidwa makamaka ndi madera athyathyathya ndi kung'amba m'mphepete, zomwe zimasonyeza kuti fracture ya fracture ya fracture inali yaikulu kwambiri. The fracture morphology of the alloy after extrusion yasintha kwambiri, ndipo fracture imapangidwa ndi chiwerengero chachikulu cha dimples equiaxed, kusonyeza kuti fracture limagwirira a aloyi pambuyo extrusion wasintha kuchokera brittle fracture kuti ductile fracture. Pamene chiŵerengero cha extrusion chili chaching'ono, ma dimples ndi osaya ndipo kukula kwa dimple ndi kwakukulu, ndipo kugawa kumakhala kosiyana; pamene chiŵerengero cha extrusion chikuwonjezeka, chiwerengero cha ma dimples chikuwonjezeka, kukula kwa dimple ndi kochepa ndipo kugawidwa ndi yunifolomu (Chithunzi 6b ~ f), zomwe zikutanthauza kuti alloy ali ndi pulasitiki yabwino, yomwe imagwirizana ndi zotsatira zoyesa zamakina pamwamba.

3 Mapeto

Mu kuyesera uku, zotsatira za ma ratios osiyana extrusion pa microstructure ndi katundu wa 6063 zotayidwa aloyi anali kusanthula pansi chikhalidwe kuti billet kukula, ingot kutentha kutentha ndi extrusion liwiro sanasinthe. Zotsatira zake ndi izi:

1) Dynamic recrystallization imapezeka mu 6063 aluminium alloy panthawi yotentha. Ndi kuwonjezeka kwa chiŵerengero cha extrusion, njerezo zimayengedwa mosalekeza, ndipo njere zomwe zimatalikitsidwa motsatira njira ya extrusion zimasinthidwa kukhala njere za equiaxed recrystallized, ndipo mphamvu ya <100> kapangidwe ka waya imawonjezeka mosalekeza.

2) Chifukwa cha kulimbitsa bwino kwambewu, mphamvu zamakina a aloyi zimasinthidwa ndikuwonjezeka kwa chiŵerengero cha extrusion. M'kati mwa magawo oyesera, pamene chiŵerengero cha extrusion ndi 156, mphamvu yamakokedwe ndi elongation ya aloyi imafika pazitali za 228 MPa ndi 26,9%, motero.

Chithunzi cha 6 Kuphwanya kwapang'onopang'ono kwa 6063 aluminium alloy pambuyo poponyedwa ndi extrusion.

3) The fracture morphology of the as-cast specimen imapangidwa ndi madera athyathyathya ndi m'mbali zong'ambika. Pambuyo pa extrusion, fracture imapangidwa ndi ma dimples ambiri omwe amafanana, ndipo njira yowonongeka imasinthidwa kuchoka ku brittle fracture kupita ku ductile fracture.

Nthawi yotumiza: Nov-30-2024