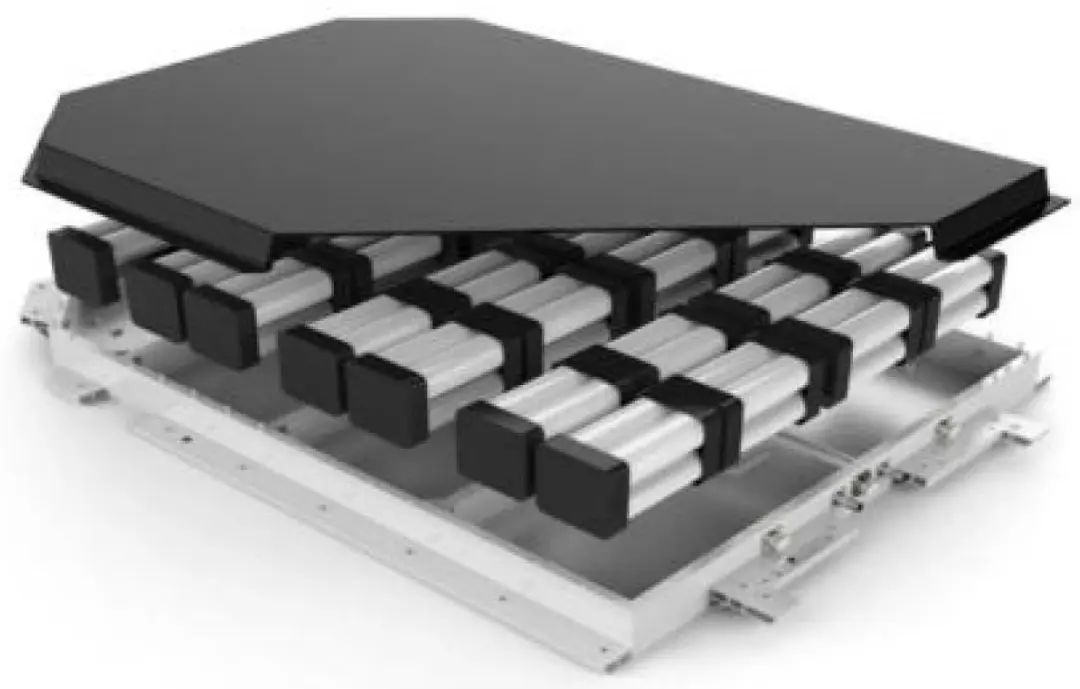

Batire ndiye gawo lalikulu lagalimoto yamagetsi, ndipo magwiridwe ake amatsimikizira zizindikiro zaukadaulo monga moyo wa batri, kugwiritsa ntchito mphamvu, komanso moyo wautumiki wagalimoto yamagetsi. Sireyi ya batri mu gawo la batri ndi gawo lalikulu lomwe limagwira ntchito zonyamula, kuteteza, ndi kuziziritsa. Phukusi la batri la modular limakonzedwa mu thireyi ya batri, yokhazikika pa chassis ya galimoto kupyolera mu thireyi ya batri, monga momwe tawonetsera pa Chithunzi 1. Popeza imayikidwa pansi pa thupi la galimoto ndipo malo ogwirira ntchito ndi ovuta, thireyi ya batri iyenera kukhala ndi ntchito yolepheretsa kukhudzidwa kwa miyala ndi puncture kuti muteteze gawo la batri kuti lisawonongeke. Tireyi ya batri ndi gawo lofunikira lachitetezo cha magalimoto amagetsi. Zotsatirazi zikuwonetsa njira yopangira ndi kapangidwe ka nkhungu zama tray a aluminiyamu aloyi batire pamagalimoto amagetsi.

Chithunzi 1 (thireyi ya batire ya Aluminium alloy)

1 Kusanthula ndondomeko ndi mapangidwe a nkhungu

1.1 Kusanthula kwamasewera

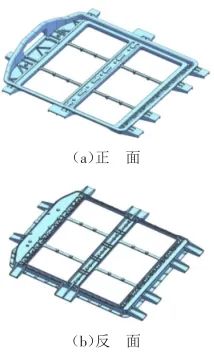

Aluminiyamu aloyi batire thireyi kwa magalimoto magetsi akuwonetsedwa Chithunzi 2. Miyeso yonse ndi 1106mm × 1029mm × 136mm, makulidwe a khoma ndi 4mm, khalidwe loponyera lili pafupi 15.5kg, ndipo khalidwe loponyera pambuyo pokonza lili pafupi 12.5kg. Zomwe zili ndi A356-T6, Kulimba Kwambiri ≥ 290MPa, mphamvu zokolola ≥ 225MPa, elongation ≥ 6%, Brinell hardness ≥ 75 ~ 90HBS, imayenera kukwaniritsa kulimba kwa mpweya ndi IP67 & IP69K zofunika.

Chithunzi 2 (thireyi ya batire ya Aluminium alloy)

1.2 Kusanthula ndondomeko

Low pressure die casting ndi njira yapadera yoponyera pakati pa kuponyera ndi kuponya mphamvu yokoka. Sikuti ali ndi ubwino wogwiritsa ntchito nkhungu zachitsulo kwa onse awiri, komanso ali ndi makhalidwe a kudzazidwa kokhazikika. Low pressure die casting ili ndi maubwino a kudzaza kothamanga kwambiri kuchokera pansi kupita pamwamba, kosavuta kuwongolera liwiro, kugunda pang'ono ndi kuwaza kwa aluminiyamu yamadzimadzi, kuchepera kwa oxide slag, kachulukidwe kakang'ono ka minofu komanso makina apamwamba kwambiri. Pansi otsika kuthamanga kufa kuponyera, zotayidwa madzi wodzazidwa bwino, ndi kuponyera solidifies ndi crystallizes pansi pa kupsyinjika, ndi kuponyera ndi kapangidwe mkulu wandiweyani, mkulu mawotchi katundu ndi maonekedwe okongola akhoza analandira, amene ali oyenera kupanga lalikulu woonda-mipanda castings.

Malinga ndi katundu makina chofunika ndi kuponyera, zinthu kuponyera ndi A356, amene angakwaniritse zosowa za makasitomala pambuyo mankhwala T6, koma kuthira fluidity za nkhaniyi zambiri amafuna wololera kulamulira nkhungu kutentha kubala castings lalikulu ndi woonda.

1.3 Njira yothira

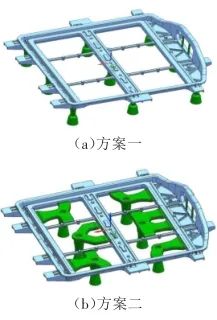

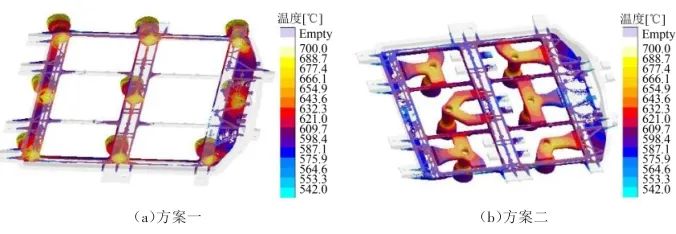

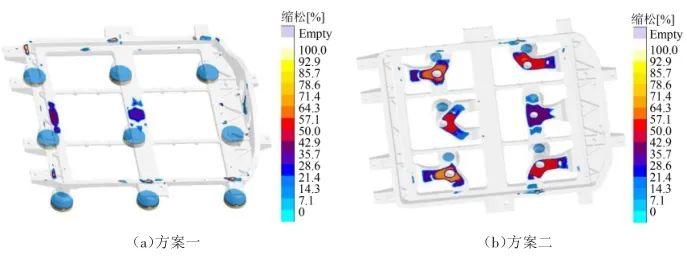

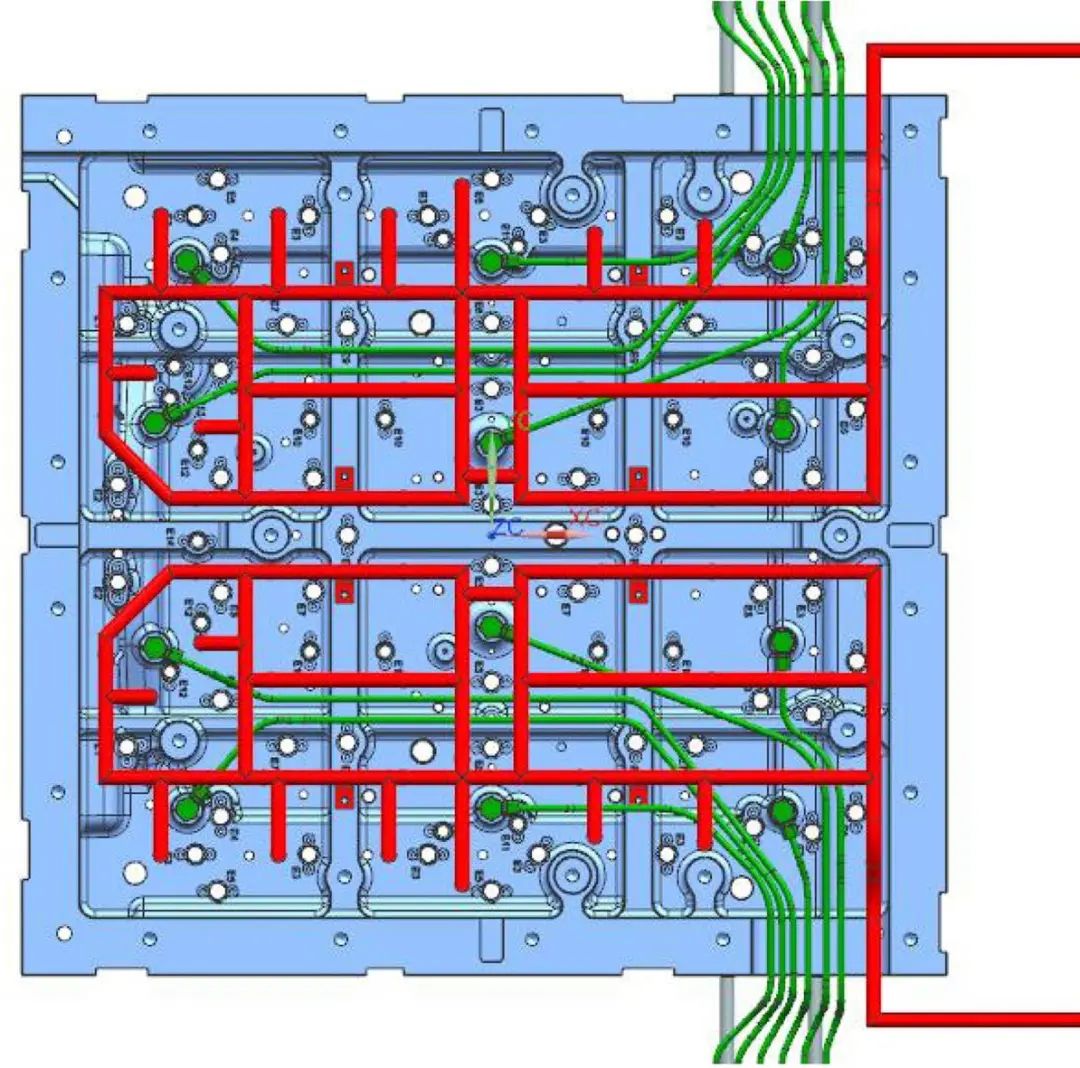

Poganizira mawonekedwe a ma castings akulu ndi owonda, zipata zingapo ziyenera kupangidwa. Panthawi imodzimodziyo, pofuna kuonetsetsa kuti kudzazidwa kosalala kwa aluminiyamu yamadzimadzi, njira zodzaza zimawonjezeredwa pawindo, zomwe ziyenera kuchotsedwa ndi post-processing. Njira ziwiri zoyendetsera dongosolo la kuthira zidapangidwa koyambirira, ndipo chiwembu chilichonse chinafaniziridwa. Monga momwe tawonetsera pa Chithunzi 3, chiwembu cha 1 chimakonza zipata za 9 ndikuwonjezera njira zodyera pawindo; chiwembu 2 amakonza zipata 6 kutsanulira kuchokera kumbali ya kuponyera kuti apangidwe. Kusanthula kayeseleledwe ka CAE kukuwonetsedwa mu Chithunzi 4 ndi Chithunzi 5. Gwiritsani ntchito zotsatira zofananira kuti mukwaniritse bwino mawonekedwe a nkhungu, yesetsani kupeŵa zotsatira zoyipa za mapangidwe a nkhungu pa khalidwe la castings, kuchepetsa kuthekera kwa kuponyera zolakwika, ndikufupikitsa chitukuko cha castings.

Chithunzi 3 (Kuyerekeza kwa njira ziwiri zoyendetsera kupanikizika kochepa

Chithunzi 4 (Kuyerekeza kwa gawo la kutentha pakudzaza)

Chithunzi 5 (Kuyerekeza kwa shrinkage porosity defects pambuyo kulimbitsa)

The kayeseleledwe zotsatira za ziwembu ziwiri pamwamba kusonyeza kuti zotayidwa madzi mu patsekeke zimayenda m'mwamba pafupifupi kufanana, zomwe zimagwirizana ndi chiphunzitso cha kufanana kudzazidwa kwa aluminiyamu madzi lonse, ndi yoyerekeza shrinkage porosity mbali za kuponyera amathetsedwa ndi kulimbikitsa kuzirala ndi njira zina.

Ubwino wa ziwembu ziwiri: Tikayang'ana kutentha kwa aluminiyamu madzi pa yoyerekeza kudzazidwa, kutentha kwa distal mapeto a kuponyera opangidwa ndi chiwembu 1 ali apamwamba yunifolomu kuposa chiwembu 2, amene amathandiza kuti kudzazidwa kwa patsekeke. Kuponyedwa kopangidwa ndi chiwembu 2 kulibe zotsalira zachipata monga chiwembu 1. shrinkage porosity ndiyabwino kuposa ya chiwembu 1.

Zoyipa za ziwembu ziwirizi: Chifukwa chipatacho chimakonzedwa pakuponyedwa kuti chipangidwe mu chiwembu 1, padzakhala zotsalira zachipata pakuponyedwa, zomwe zidzawonjezeka pafupifupi 0,7ka poyerekeza ndi kuponyedwa koyambirira. kuchokera kutentha kwa aluminiyamu madzi mu chiwembu 2 kayeseleledwe kudzazidwa, kutentha kwa aluminiyamu madzi pa distal mapeto kale otsika, ndi kayeseleledwe ali pansi pa chikhalidwe chabwino cha nkhungu kutentha, kotero otaya mphamvu ya zotayidwa madzi kungakhale kosakwanira mu mkhalidwe weniweniwo, ndipo padzakhala vuto la kuvutika kuponyera akamaumba.

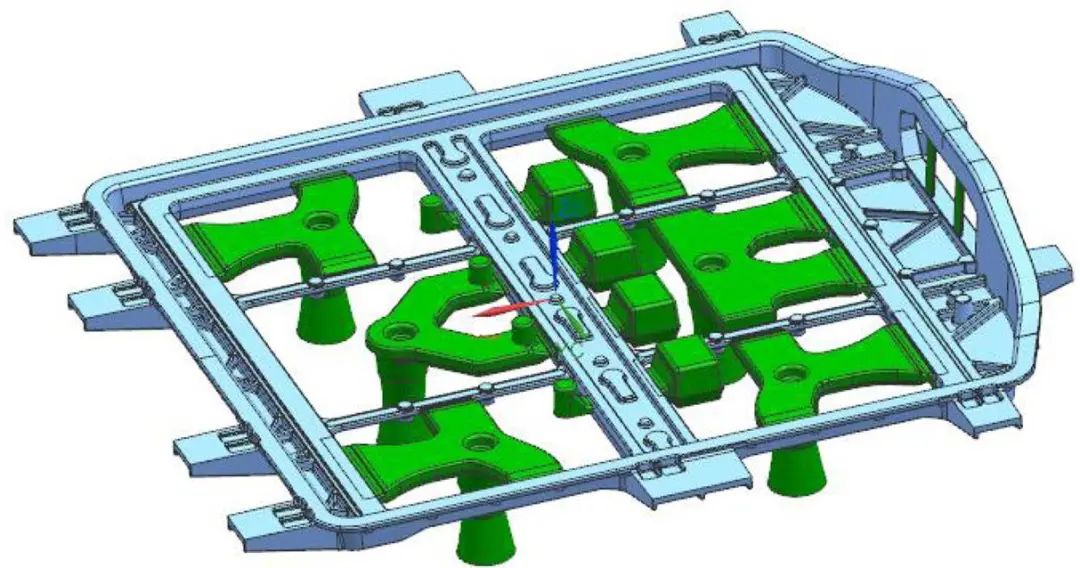

Kuphatikizidwa ndi kusanthula kwazinthu zosiyanasiyana, chiwembu 2 chinasankhidwa ngati njira yothira. Poganizira zolakwika za chiwembu 2, makina otsanulira ndi makina otenthetsera amakonzedwa bwino pamapangidwe a nkhungu. Monga momwe tawonetsera pa Chithunzi 6, chokwera chochulukirapo chimawonjezedwa, chomwe chimakhala chopindulitsa pakudzaza kwa aluminiyamu yamadzimadzi ndikuchepetsa kapena kupewa kupezeka kwa zolakwika muzoponyera zowumbidwa.

Chithunzi 6 (Mchitidwe wothira wokometsedwa)

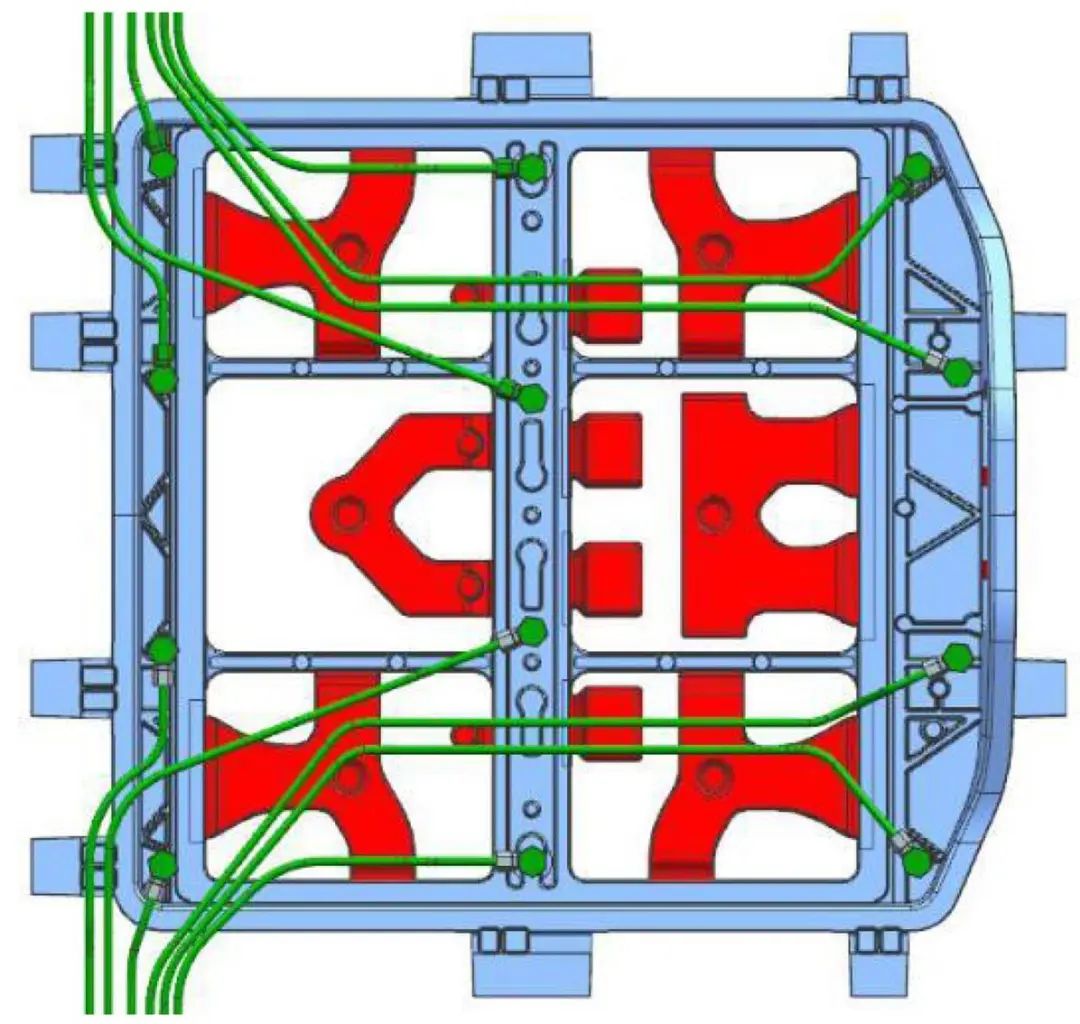

1.4 Dongosolo lozizira

Zigawo zokhala ndi nkhawa komanso madera omwe ali ndi zofunikira zamakina opangira ma castings ayenera kuziziritsidwa bwino kapena kudyetsedwa kuti zisawonongeke kapena kuphulika kwamafuta. Makulidwe oyambira a khoma la kuponyera ndi 4mm, ndipo kulimba kumakhudzidwa ndi kutentha kwa nkhungu komweko. Pazigawo zake zofunika, dongosolo lozizira limakhazikitsidwa, monga momwe tawonetsera pa Chithunzi 7. Pambuyo podzaza kudzazidwa, perekani madzi kuti aziziritsa, ndipo nthawi yeniyeni yozizira iyenera kusinthidwa pa malo othiramo kuti zitsimikizire kuti ndondomeko yokhazikika imapangidwira kuchokera kutali ndi chipata mpaka kumapeto kwa chipata, ndipo chipata ndi riser zimakhazikika pamapeto kuti zikwaniritse zotsatira za chakudya. Gawo lomwe lili ndi makulidwe okulirapo amatengera njira yowonjezerera kuziziritsa kwamadzi ndikuyikapo. Njirayi imakhala ndi zotsatira zabwino mu ndondomeko yeniyeni yoponyera ndipo imatha kupewa shrinkage porosity.

Chithunzi 7 (Dongosolo Lozizira)

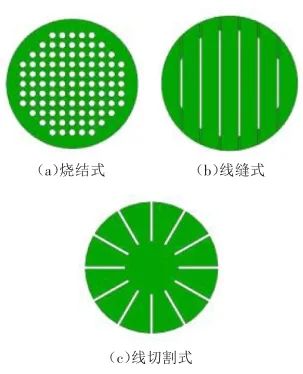

1.5 Dongosolo la exhaust

Popeza patsekeke ya chitsulo choponderezedwa chotsika chatsekedwa, sichikhala ndi mpweya wabwino ngati nkhungu zamchenga, komanso sichimatuluka kudzera muzokwera mozungulira mphamvu yokoka, kutulutsa kwapang'onopang'ono kukhudza kudzaza kwa aluminiyamu yamadzimadzi komanso mtundu wa castings. The otsika kuthamanga kufa kuponyera nkhungu akhoza wotopa kudzera mipata, utsi grooves ndi utsi mapulagi mu molekanitsa pamwamba, kukankha ndodo etc.

Mapangidwe a kukula kwa mpweya muzitsulo zotulutsa mpweya ayenera kukhala zothandiza kuti zithetse popanda kusefukira, njira yabwino yothetsera vutoli ingalepheretse kuponyera ku zolakwika monga kudzaza kosakwanira, kutayirira, ndi mphamvu zochepa. Malo omaliza odzaza ndi aluminiyumu yamadzimadzi panthawi yothira, monga mpumulo wam'mbali ndi chokwera cha nkhungu chakumtunda, ayenera kukhala ndi mpweya wotulutsa mpweya. Poona chakuti zotayidwa madzi mosavuta umayenda mu kusiyana kwa pulagi utsi mu ndondomeko yeniyeni ya otsika kuthamanga kufa kuponyera, zomwe zimabweretsa zinthu kuti pulagi mpweya ndi chikoka pamene nkhungu anatsegula, njira zitatu anatengera pambuyo zoyesayesa zingapo ndi kusintha: Njira 1 ntchito ufa zitsulo sintered mpweya pulagi, monga momwe chithunzi chithunzi 8(kuipa ndi mkulu); Njira 2 imagwiritsa ntchito pulagi yamtundu wa msoko wokhala ndi kusiyana kwa 0.1 mm, monga momwe tawonetsera pa Chithunzi 8 (b), choyipa ndi chakuti msoko wotulutsa mpweya umatsekedwa mosavuta pambuyo popopera utoto; Njira 3 imagwiritsa ntchito pulagi yotulutsa waya, kusiyana kwake ndi 0.15 ~ 0.2 mm, monga momwe tawonetsera pa Chithunzi 8 (c). The kuipa ndi otsika processing dzuwa ndi mkulu kupanga mtengo. Mapulagi osiyana otulutsa mpweya ayenera kusankhidwa molingana ndi malo enieni a kuponyera. Nthawi zambiri, mapulagi a sintered ndi odulidwa ndi waya amagwiritsidwa ntchito pobowoleza, ndipo mtundu wa msoko umagwiritsidwa ntchito pamutu wamchenga.

Chithunzi 8 (Mitundu ya 3 ya mapulagi otulutsa mpweya oyenera kuponyera kwapansi)

1.6 Dongosolo lotenthetsera

Chojambulacho ndi chachikulu kukula kwake komanso kocheperako pamakoma. Pakuwunika kwa nkhungu, kuthamanga kwa aluminiyumu yamadzimadzi kumapeto kwa kudzaza sikukwanira. Chifukwa chake n'chakuti aluminiyamu yamadzimadzi ndi yaitali kwambiri kuti isasunthike, kutentha kumatsika, ndi aluminiyumu yamadzimadzi imakhazikika pasadakhale ndipo imataya mphamvu yake yothamanga, kutsekedwa kozizira kapena kutsanulira kosakwanira kumachitika, chokwera chapamwamba chakufa sichidzatha kukwaniritsa zotsatira za kudyetsa. Kutengera ndi mavutowa, popanda kusintha makulidwe a khoma ndi mawonekedwe a kuponyera, onjezerani kutentha kwa aluminiyamu yamadzimadzi ndi kutentha kwa nkhungu, kusintha madzi a aluminiyamu yamadzimadzi, ndikuthetsa vuto la kutsekedwa kozizira kapena kuthira kosakwanira. Komabe, kutentha kwambiri kwa aluminiyumu yamadzimadzi ndi kutentha kwa nkhungu kumatulutsa matenthedwe atsopano kapena shrinkage porosity, zomwe zimapangitsa kuti pakhale ma pinholes a ndege pambuyo poponya. Chifukwa chake, ndikofunikira kusankha kutentha koyenera kwa aluminiyumu yamadzimadzi komanso kutentha kwa nkhungu koyenera. Malinga ndi chidziwitso, kutentha kwa aluminiyamu yamadzimadzi kumayendetsedwa pafupifupi 720 ℃, ndipo kutentha kwa nkhungu kumayendetsedwa pa 320 ~ 350 ℃.

Poyang'ana kuchuluka kwakukulu, makulidwe a khoma laling'ono ndi kutalika kochepa kwa kuponyera, makina otenthetsera amaikidwa pamwamba pa nkhungu. Monga momwe tawonetsera pa Chithunzi 9, mayendedwe a lawi akuyang'ana pansi ndi mbali ya nkhungu kuti atenthe ndege yapansi ndi mbali ya kuponyera. Malinga ndi momwe kuthirira pamalopo, sinthani nthawi yotenthetsera ndi lawi lamoto, wongolerani kutentha kwa gawo lapamwamba la nkhungu pa 320 ~ 350 ℃, onetsetsani kuti aluminiyumu yamadzimadzi imakhala yokwanira, ndikupangitsa kuti aluminiyumu yamadzimadzi idzaze pabowo ndi chokwera. Pogwiritsira ntchito, makina otenthetsera amatha kuonetsetsa kuti madzi a aluminiyamu amadzimadzimadzi.

Chithunzi 9 (Heating system)

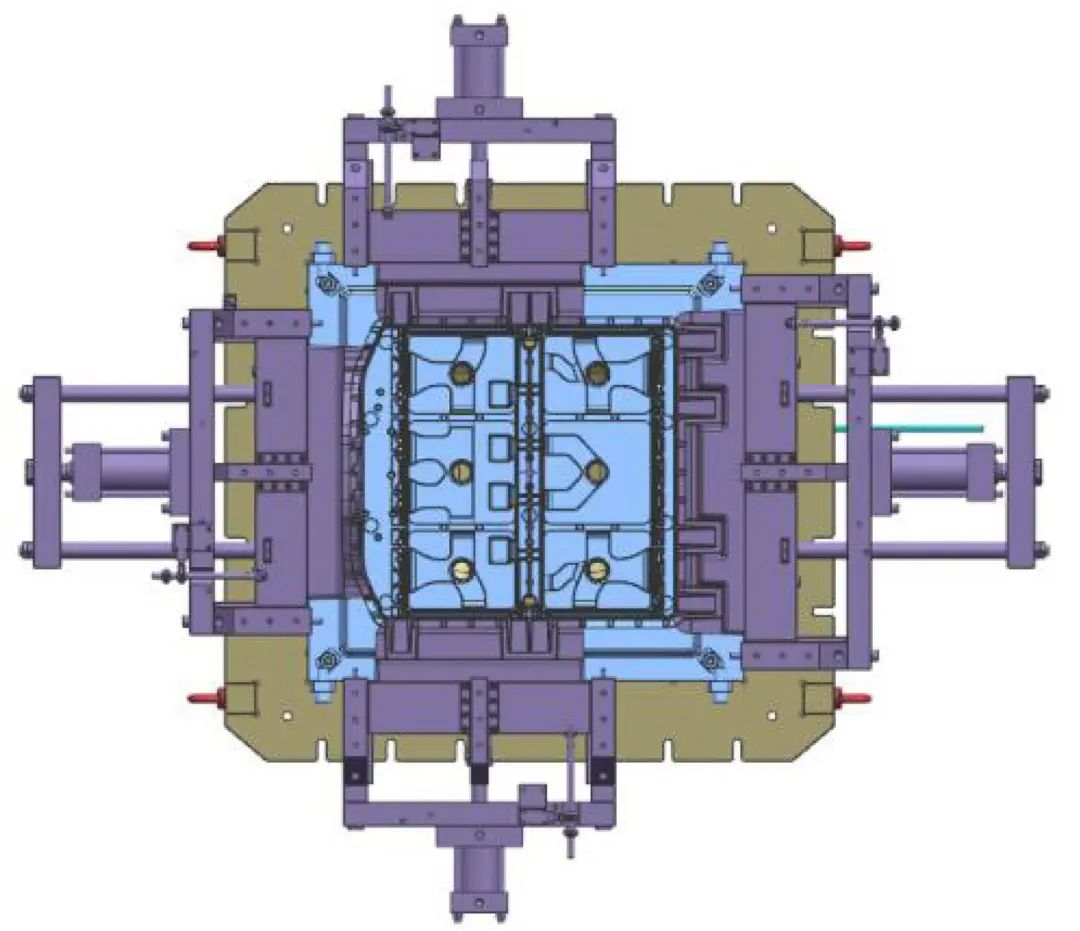

2. Mapangidwe a nkhungu ndi mfundo yogwirira ntchito

Malinga ndi otsika kuthamanga kufa kuponyera ndondomeko, kuphatikizapo makhalidwe a kuponyera ndi dongosolo la zida, pofuna kuonetsetsa kuti kuponya anapanga amakhala mu nkhungu chapamwamba, kutsogolo, kumbuyo, kumanzere ndi kumanja pachimake-chikoka nyumba zakonzedwa pa nkhungu chapamwamba. Pambuyo kuponyedwa kupangidwa ndi kukhazikika, zoumba zapamwamba ndi zapansi zimatsegulidwa poyamba, ndiyeno kukoka pachimake mu njira 4, ndipo potsiriza mbale yapamwamba ya nkhungu yapamwamba imakankhira kunja kuponyedwa komwe kunapangidwa. Mapangidwe a nkhungu akuwonetsedwa mu Chithunzi 10.

Chithunzi 10 (Kapangidwe ka nkhungu)

Adasinthidwa ndi May Jiang kuchokera ku MAT Aluminium

Nthawi yotumiza: May-11-2023