Kupepuka kwa magalimoto ndi cholinga chogawana nawo pamakampani opanga magalimoto padziko lonse lapansi. Kuchulukitsa kugwiritsa ntchito zida za aluminiyamu aloyi m'zigawo zamagalimoto ndikuwongolera kwa magalimoto amakono amtundu watsopano. 6082 aluminiyamu aloyi ndi kutentha kutentha, kulimbikitsa zotayidwa aloyi ndi mphamvu zolimbitsa, mawonekedwe abwino, weldability, kukana kutopa, ndi kukana dzimbiri. Aloyi imeneyi akhoza extruded mu mapaipi, ndodo, ndi mbiri, ndipo chimagwiritsidwa ntchito zigawo magalimoto, welded mbali structural, mayendedwe, ndi makampani zomangamanga.

Pakalipano, pali kafukufuku wochepa pa 6082 aluminium alloy kuti agwiritsidwe ntchito pamagalimoto atsopano amphamvu ku China. Chifukwa chake, kafukufuku woyesererawa amafufuza momwe 6082 aluminium alloy aloyi amasinthira, magawo opangira ma extrusion, njira zozimitsa, ndi zina zambiri, pakuchita kwa mbiri ya alloy ndi microstructure. Kafukufukuyu akufuna kukhathamiritsa kapangidwe ka aloyi ndikusintha magawo kuti apange 6082 aluminiyamu aloyi zida zoyenera kuyendetsa magalimoto atsopano.

1. Zida Zoyesera ndi Njira

Mayendedwe oyesera: Chiŵerengero cha aloyi - Kusungunuka kwa Ingot - Ingot homogenization - Ingot sawing mu billets - Extrusion of profiles - In-line quenching of profiles - Ukalamba Wopanga - Kukonzekera zitsanzo zoyesa.

1.1 Kukonzekera kwa Ingot

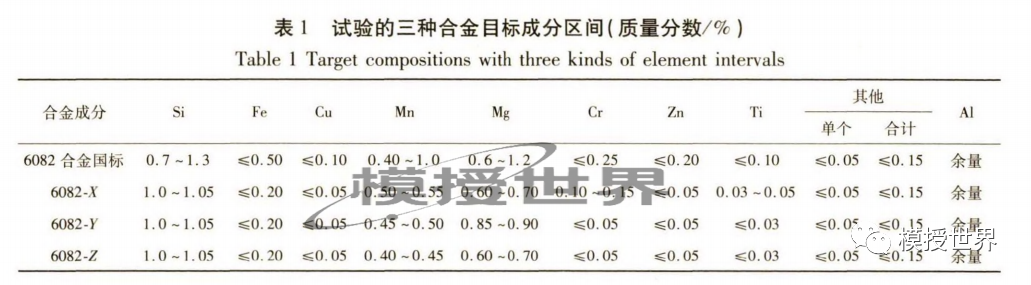

M'mitundu yapadziko lonse lapansi yamitundu 6082 ya aluminiyamu aloyi, nyimbo zitatu zidasankhidwa zokhala ndi zowongolera zocheperako, zolembedwa kuti 6082-/6082″, 6082-Z, zomwe zili ndi Si element. Mg zomwe zili mkati, y > z; Mn zinthu, x > y > z; Cr, zinthu za Ti, x > y = z. Zolinga zenizeni za alloy zikufotokozedwa mu Table 1. Kuponyedwa kwa ingot kunkachitika pogwiritsa ntchito njira yopopera yoziziritsa madzi yopitilira theka, yotsatiridwa ndi chithandizo cha homogenization. Ma ingots onse atatu adapangidwa homogenized pogwiritsa ntchito makina opangidwa ndi fakitale pa 560 ° C kwa maola awiri ndi kuziziritsa kwa nkhungu yamadzi.

1.2 Kutulutsa Mbiri

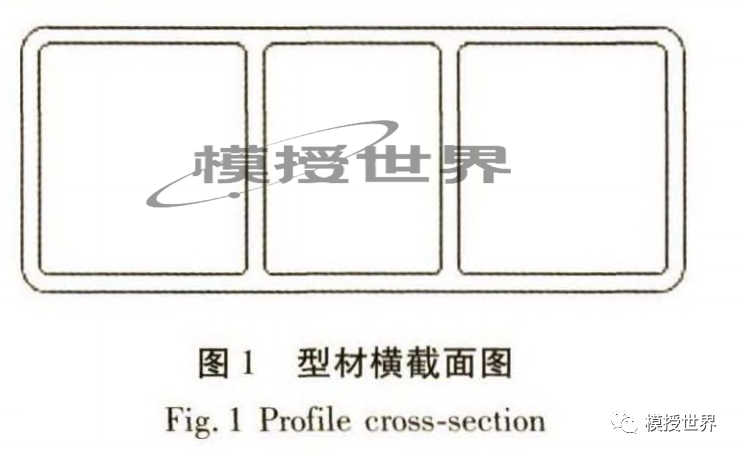

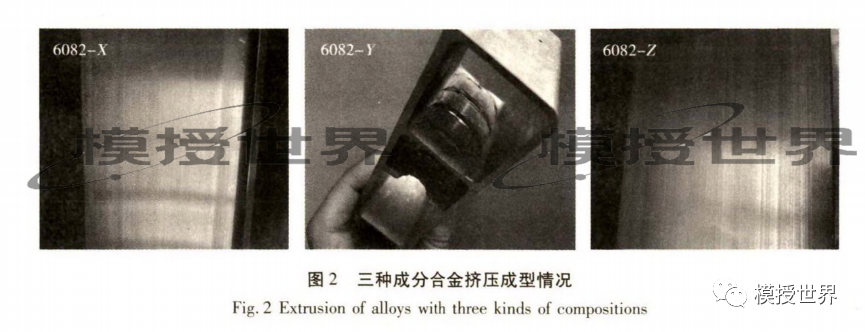

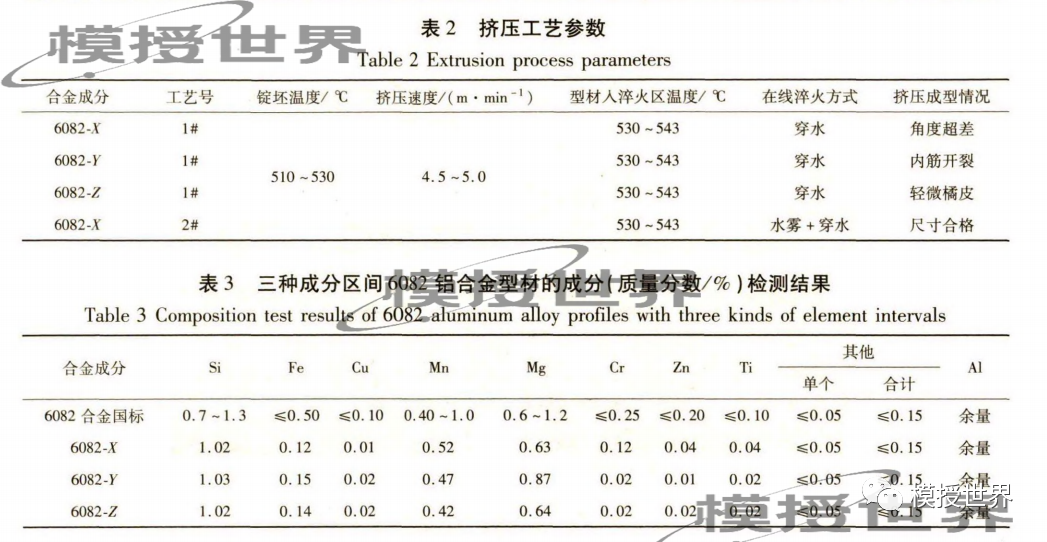

The extrusion ndondomeko magawo anasinthidwa moyenera billet kutentha kutentha ndi quenching mlingo kuzirala. Chigawo cham'mbali cha ma profiles otulutsidwa chikuwonetsedwa mu Chithunzi 1. Zomwe zimapangidwira zowonjezera zikuwonetsedwa mu Table 2. Kupanga mawonekedwe a ma profayilo otulutsidwa kukuwonetsedwa mu Chithunzi 2.

2.Kuyesa Zotsatira ndi Kusanthula

Kapangidwe kake ka ma profiles a 6082 aluminiyamu aloyi mkati mwa magawo atatu omwe adapangidwa adatsimikiziridwa pogwiritsa ntchito Swiss ARL yowerengera molunjika spectrometer, monga momwe tawonetsera mu Gulu 3.

2.1 Kuyesa Kuchita

Kuti tifananize, magwiridwe antchito amitundu itatu yamitundu yosiyanasiyana ya aloyi ndi njira zosiyanasiyana zozimitsa, magawo ofanana a extrusion, ndi ukalamba adawunikidwa.

2.1.1 Magwiridwe Amakina

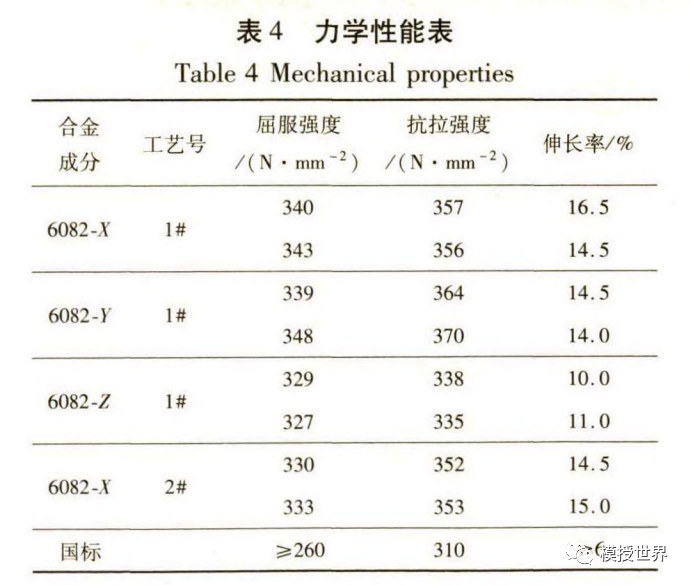

Pambuyo pa ukalamba wochita kupanga pa 175 ° C kwa maola 8, zitsanzo zokhazikika zinatengedwa kuchokera kumalo opangira ma profayilo kuti ayesedwe movutikira pogwiritsa ntchito makina a Shimadzu AG-X100 oyesera padziko lonse lapansi. Kuchita kwamakina pambuyo pa kukalamba kochita kupanga kwa nyimbo zosiyanasiyana ndi njira zozimitsa zikuwonetsedwa mu Gulu 4.

Kuchokera pa Table 4, zitha kuwoneka kuti machitidwe amakanika a mbiri yonse amaposa miyezo yapadziko lonse lapansi. Mbiri zopangidwa kuchokera ku 6082-Z alloy billets zinali ndi kutalika kochepa pambuyo pakusweka. Mbiri zopangidwa kuchokera ku 6082-7 alloy billets zinali ndi makina apamwamba kwambiri. Mbiri ya aloyi ya 6082-X, yokhala ndi njira zosiyanasiyana zoyankhira, idawonetsa magwiridwe antchito apamwamba ndi njira zoziziritsira mwachangu.

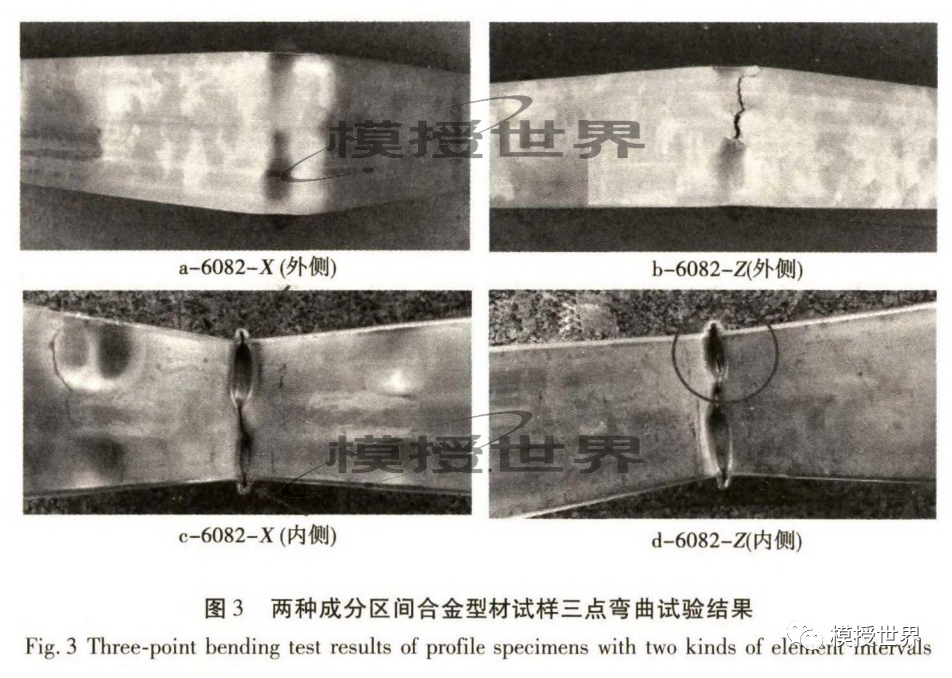

2.1.2 Kuyesa Magwiridwe Opindika

Pogwiritsa ntchito makina oyesera amagetsi padziko lonse lapansi, mayesero atatu opindika adachitidwa pazitsanzo, ndipo zotsatira zopindika zikuwonetsedwa mu Chithunzi 3. Chithunzi 3 chikuwonetsa kuti mankhwala opangidwa kuchokera ku 6082-Z alloy billets anali ndi peel yaikulu ya lalanje pamwamba ndi kusweka kumbuyo kwa zitsanzo zopindika. Zopangidwa kuchokera ku 6082-X alloy billets zinali ndi ntchito yopindika bwino, malo osalala opanda peel lalanje, komanso ming'alu yaying'ono pamagawo ocheperako ndi mawonekedwe a geometric kumbuyo kwa zitsanzo zopindika.

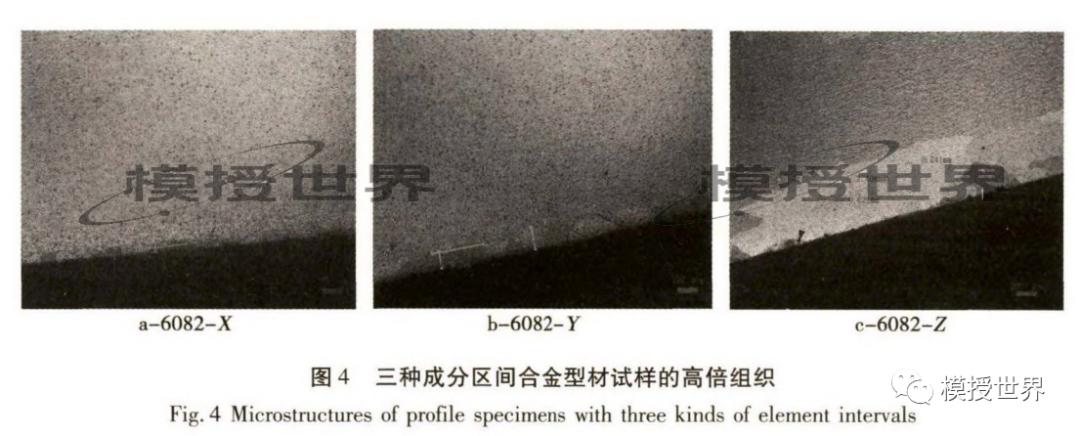

2.1.3 Kuyang'ana Kwambiri

Zitsanzo zidawonedwa pansi pa microscope ya Carl Zeiss AX10 yowunikira ma microstructure. Zotsatira za kusanthula kwa microstructure kwa ma profiles atatu amtundu wa alloy akuwonetsedwa mu Chithunzi 4. Chithunzi 4 chikuwonetsa kuti kukula kwa mbewu zamagulu opangidwa kuchokera ku 6082-X ndodo ndi 6082-K alloy billets zinali zofanana, ndi kukula kwa tirigu wabwinoko pang'ono mu 6082-X alloy poyerekeza ndi 6082-y alloy. Zopangidwa kuchokera ku 6082-Z alloy billets zinali ndi makulidwe okulirapo a tirigu ndi zigawo zokulirapo za kotekisi, zomwe zidapangitsa kuti ma peel alalanje awonekere komanso kufooketsa zitsulo zamkati.

2.2 Kusanthula Zotsatira

Kutengera zotsatira za mayeso omwe ali pamwambapa, titha kunena kuti mapangidwe amitundu yosiyanasiyana ya alloy amakhudza kwambiri mawonekedwe a microstructure, magwiridwe antchito, komanso mawonekedwe amtundu wa extruded. Kuchuluka kwa zinthu za Mg kumachepetsa pulasitiki ya alloy ndikupangitsa kuti ming'alu ipangidwe panthawi ya extrusion. Zomwe zili mu Mn, Cr, ndi Ti zili ndi zotsatira zabwino pakuyenga mawonekedwe ang'onoang'ono, omwe amakhudzanso mawonekedwe a pamwamba, kupindika, ndi magwiridwe antchito onse.

3.Mapeto

Mg element imakhudza kwambiri magwiridwe antchito a 6082 aluminium alloy. Kuchulukitsidwa kwa Mg kumachepetsa pulasitiki ya alloy ndipo kumabweretsa kupanga ming'alu panthawi ya extrusion.

Mn, Cr, ndi Ti ali ndi zotsatira zabwino pakuwongolera ma microstructure, zomwe zimapangitsa kuti pakhale mawonekedwe apamwamba komanso kupindika kwa zinthu zomwe zatulutsidwa.

Kuzizira kosiyanasiyana kozimitsa kumakhudza kwambiri magwiridwe antchito a 6082 aluminiyamu aloyi mbiri. Pogwiritsa ntchito magalimoto, kugwiritsa ntchito njira yozimitsa nkhungu yamadzi yotsatiridwa ndi kuziziritsa kwamadzi kumapereka magwiridwe antchito amakina ndikuwonetsetsa kuti mbiriyo ndi yolondola komanso yolondola.

Adasinthidwa ndi May Jiang kuchokera ku MAT Aluminium

Nthawi yotumiza: Mar-26-2024