1.Chiyambi

Ma aluminiyamu aloyi okhala ndi mphamvu yapakatikati amawonetsa mawonekedwe abwino opangira, kuzimitsa kukhudzika, kulimba kwamphamvu, komanso kukana dzimbiri.Amagwiritsidwa ntchito kwambiri m'mafakitale osiyanasiyana, monga zamagetsi ndi zam'madzi, popanga mapaipi, ndodo, mbiri, ndi mawaya.Pakadali pano, pakufunika kuwonjezeka kwa mipiringidzo ya 6082 aluminium alloy.Kuti tikwaniritse zofuna za msika ndi zofunikira za ogwiritsa ntchito, tidayesa njira zosiyanasiyana zotenthetsera zowonjezera komanso njira zomaliza zochizira kutentha kwa mipiringidzo ya 6082-T6.Cholinga chathu chinali kuzindikira njira yochizira kutentha yomwe imakwaniritsa zofunikira zamakina pamipiringidzo iyi.

2.Zoyeserera Zoyeserera ndi Njira Yopanga Kuyenda

2.1 Zida Zoyesera

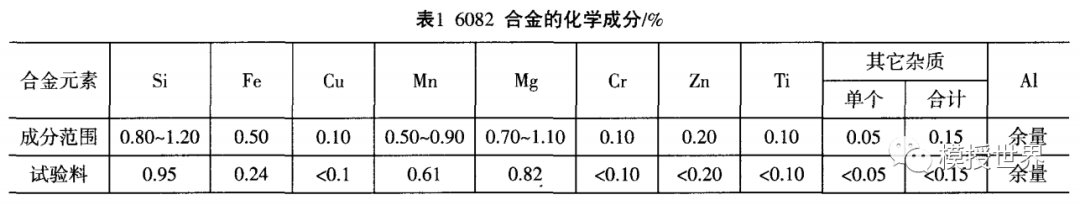

Kuponyera ma ingot a kukula Ф162 × 500 anapangidwa pogwiritsa ntchito njira yopangira theka-yopitilira ndikupatsidwa chithandizo chosafanana.Ubwino wazitsulo wa ingots umagwirizana ndi miyezo yaukadaulo yamakampani.Kapangidwe kakemidwe ka aloyi 6082 akuwonetsedwa mu Gulu 1.

2.2 Kuyenda kwa Njira Yopanga

Mipiringidzo ya 6082 yoyesera inali ndi mawonekedwe a Ф14mm.The extrusion chidebe anali awiri a Ф170mm ndi 4-hole extrusion kapangidwe ndi extrusion coefficient 18.5.Kuthamanga kwapadera kumaphatikizapo kutentha kwa ingot, extrusion, kuzimitsa, kutambasula kuwongola ndi sampuli, kuwongola kwa roller, kudula komaliza, kukalamba kochita kupanga, kuyang'anira khalidwe, ndi kutumiza.

3.Zolinga Zoyesera

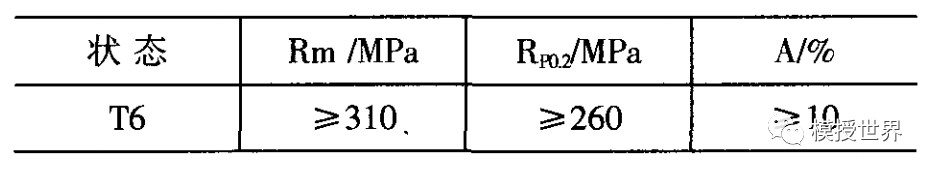

Cholinga cha phunziroli chinali kuzindikira magawo opangira kutentha kwa extrusion ndi magawo omaliza ochizira kutentha omwe amakhudza magwiridwe antchito a mipiringidzo ya 6082-T6, pomaliza kukwaniritsa zofunikira zoyenera.Malinga ndi miyezo, ma longitudinal mechanical properties a 6082 alloy ayenera kukwaniritsa zomwe zalembedwa mu Table 2.

4.Njira Yoyesera

4.1 Kufufuza kwa Chithandizo cha Extrusion Heat

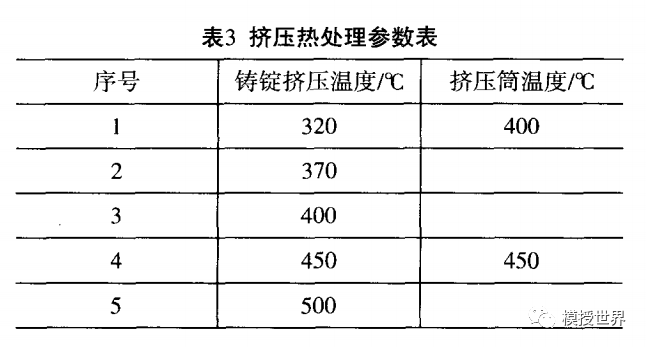

The extrusion kutentha mankhwala kafukufuku makamaka lolunjika pa zotsatira za kuponya ingot extrusion kutentha ndi extrusion chidebe kutentha pa katundu makina.Zosankha zapadera zafotokozedwa mu Table 3.

4.2 Kufufuza Kwambiri Kuthetsa Kutentha kwa Kutentha ndi Kukalamba Kwachidziwitso

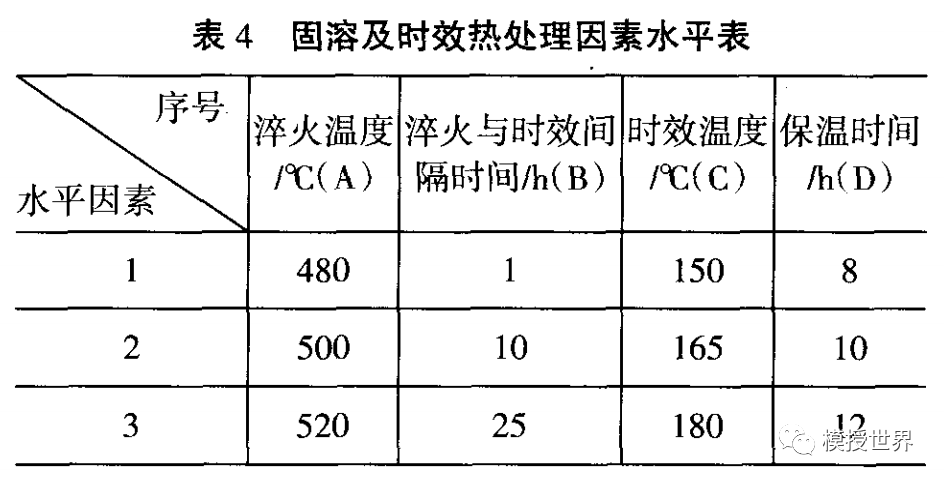

Mapangidwe oyesera a orthogonal adagwiritsidwa ntchito pofuna njira yolimba komanso njira yochiritsira kutentha kwaukalamba.Magawo osankhidwa amaperekedwa mu Table 4, ndi tebulo la orthogonal lotchedwa IJ9(34).

5.Zotsatira ndi Kusanthula

5.1 Extrusion Heat Treatment Experiment Zotsatira ndi Kusanthula

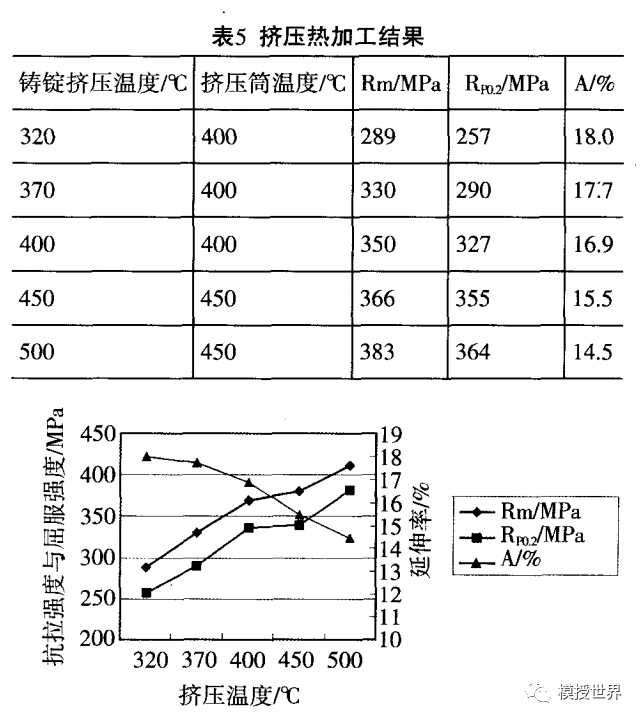

Zotsatira za kuyesa kwa chithandizo cha kutentha kwa extrusion zimaperekedwa mu Table 5 ndi Chithunzi 1. Zitsanzo zisanu ndi zinayi zinatengedwa pa gulu lirilonse, ndipo machitidwe awo amawotchi amatsimikiziridwa.Kutengera kusanthula kwa metallographic ndi kupanga mankhwala, njira yochizira kutentha idakhazikitsidwa: kuzimitsa pa 520 ° C kwa mphindi 40 ndi kukalamba pa 165 ° C kwa maola 12.Kuchokera ku Table 5 ndi Chithunzi 1, zikhoza kuwonedwa kuti pamene kutentha kwa kutentha kwa ingot extrusion ndi kutentha kwa chidebe cha extrusion kunawonjezeka, mphamvu zonse zowonongeka ndi zokolola zinawonjezeka pang'onopang'ono.Zotsatira zabwino kwambiri zidapezedwa pa kutentha kwa 450-500 ° C ndi kutentha kwa chidebe cha 450 ° C, komwe kumakwaniritsa zofunikira.Izi zidachitika chifukwa cha kuuma kwa ntchito yoziziritsa pakutentha kocheperako, kupangitsa kuti malire a tirigu aphwanyike ndikuwola kolimba pakati pa A1 ndi Mn pakuwotcha kusanazime, zomwe zimapangitsa kuti kristalo ikhale yokhazikika.Pamene kutentha kwa extrusion kunakula, mphamvu yomaliza ya Rm ya mankhwalayo inakula kwambiri.Pamene extrusion chidebe kutentha anayandikira kapena kuposa kutentha ingot, mkangano mapindikidwe utachepa, kuchepetsa kuya coarse tirigu mphete ndi kuwonjezera zokolola mphamvu Rm.Chifukwa chake, magawo oyenera ochizira kutentha kwa extrusion ndi: kutentha kwa ingot extrusion 450-500 ° C ndi kutentha kwa chidebe cha extrusion 430-450 ° C.

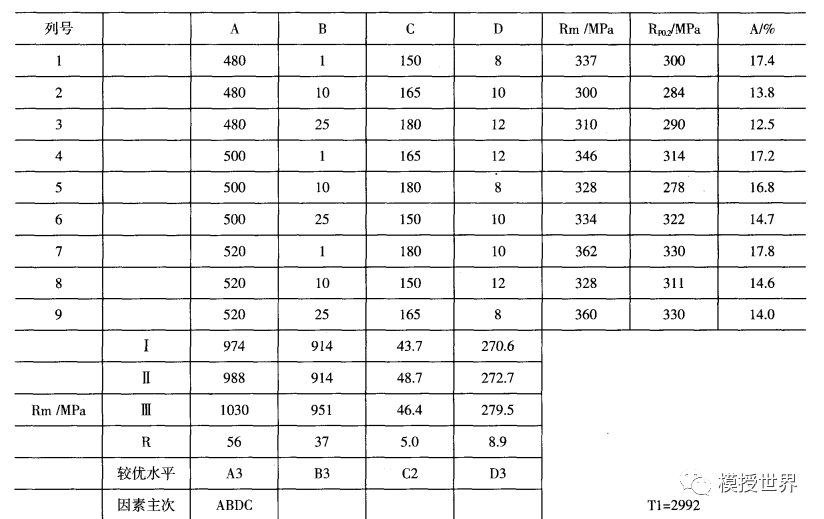

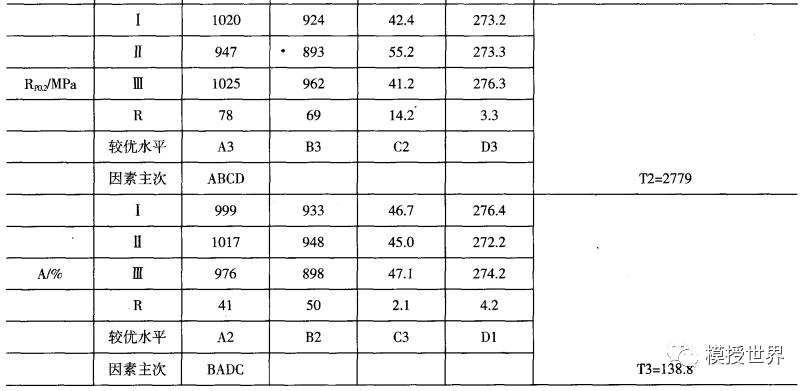

5.2 Solid Solution ndi Kukalamba Orthogonal Experimental Results ndi Analysis

Table 6 imasonyeza kuti milingo yabwino kwambiri ndi A3B1C2D3, yozimitsa pa 520 ° C, kutentha kwa ukalamba wochita kupanga pakati pa 165-170 ° C, ndi kukalamba kwa maola 12, zomwe zimapangitsa kuti pakhale mphamvu zambiri komanso pulasitiki ya mipiringidzo.Njira yozimitsa imapanga yankho la supersaturated olimba.Pa kutentha otsika quenching, ndende ya supersaturated olimba njira amachepetsa, zimakhudza mphamvu.Kutentha kozimitsa kozungulira 520 ° C kumawonjezera mphamvu ya kulimbitsa kolimba koyambitsa kuzima.The imeneyi pakati quenching ndi yokumba kukalamba, mwachitsanzo, chipinda chosungira kutentha, zimakhudza kwambiri mawotchi katundu.Izi zimatchulidwa makamaka kwa ndodo zomwe sizimatambasula pambuyo pozimitsa.Pamene nthawi pakati kuzimitsa ndi ukalamba kuposa 1 ora, mphamvu, makamaka zokolola mphamvu, amachepetsa kwambiri.

5.3 Metallographic Microstructure Analysis

Kuwunika kwakukulu komanso kusanthula kwapolarized kunachitika pazitsulo za 6082-T6 pa kutentha kolimba kwa 520 ° C ndi 530 ° C.Zithunzi zazikuluzikulu zidavumbulutsa mvula yofananirapo yokhala ndi tinthu tambiri ta precipitate gawo logawidwa mofanana.Kusanthula kwapolarized polarized pogwiritsa ntchito zida za Axiovert200 kunawonetsa kusiyana kwakukulu pazithunzi zamagulu ambewu.Malo apakati adawonetsa timbewu tating'ono ndi yunifolomu, pomwe m'mphepete mwake munawonetsa kukonzanso ndi njere zazitali.Izi zimachitika chifukwa cha kukula kwa kristalo phata pa kutentha kwambiri, kupanga coarse singano ngati precipitates.

6.Kuyesa Kuchita Zopanga

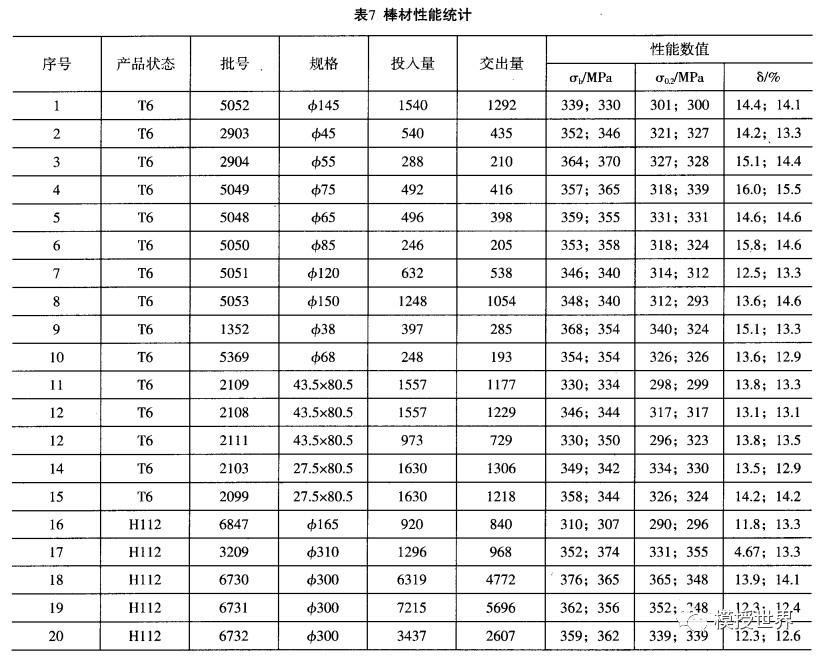

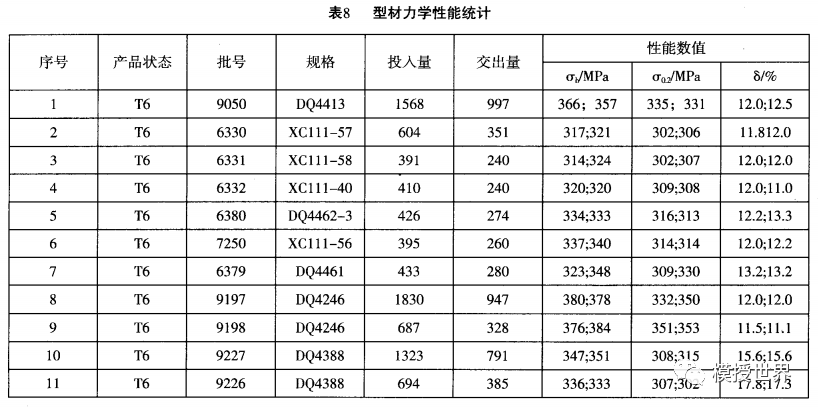

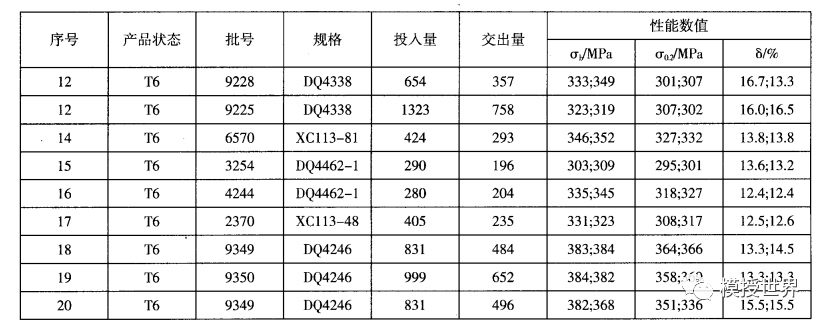

Pakupanga kwenikweni, ziwerengero zamakina zimachitidwa pamagulu 20 a mipiringidzo ndi ma 20 ma profaili.Zotsatira zikuwonetsedwa mu Matebulo 7 ndi 8. Popanga kwenikweni, njira yathu yowonjezeramo inkachitika pa kutentha komwe kumayambitsa zitsanzo za boma la T6, ndipo ntchito yamakina inakwaniritsa zofunikira.

7.Mapeto

(1) Extrusion kutentha mankhwala magawo: Ingots extrusion kutentha kwa 450-500 ° C;extrusion chidebe kutentha kwa 430-450 ° C.

(2) Magawo omaliza ochizira kutentha: Kutentha koyenera kolimba kwa 520-530 ° C;kutentha kwa ukalamba pa 165 ± 5 ° C, kukalamba kwa maola 12;nthawi pakati pa kuzimitsidwa ndi ukalamba sayenera kupitirira 1 ora.

(3) Kutengera kuwunika kothandiza, njira yopangira chithandizo cha kutentha imaphatikizapo: kutentha kwa extrusion kwa 450-530 ° C, kutentha kwa chidebe cha extrusion cha 400-450 ° C;kutentha kwazitsulo kwa 510-520 ° C;ndondomeko yokalamba ya 155-170 ° C kwa maola 12;palibe malire enieni apakati pa kuzima ndi kukalamba.Izi zikhoza kuphatikizidwa mu ndondomeko zoyendetsera ntchito.

Adasinthidwa ndi May Jiang kuchokera ku MAT Aluminium

Nthawi yotumiza: Mar-15-2024